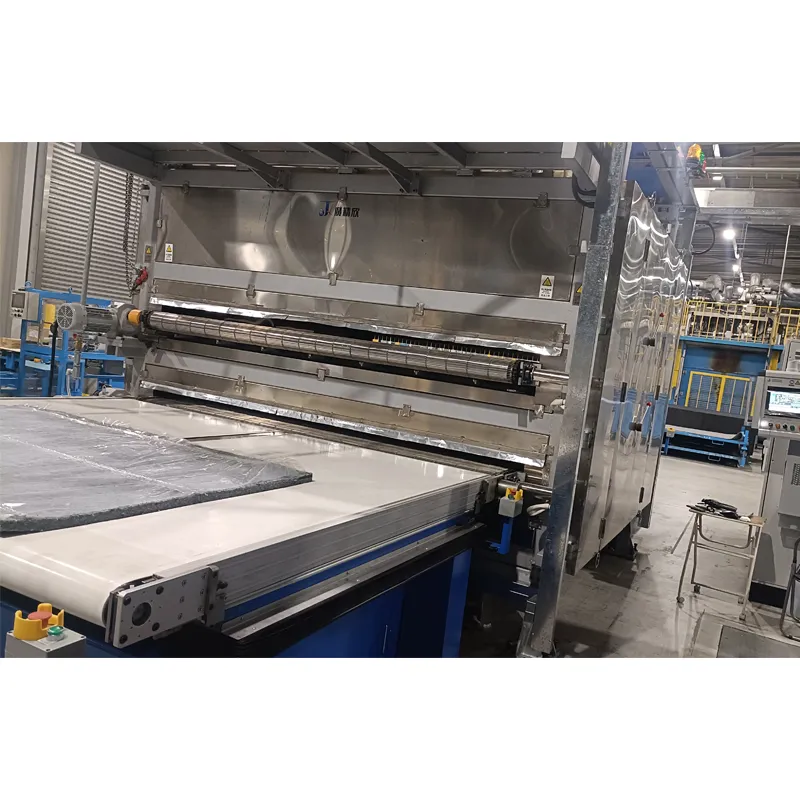

Product Description

The oven has multiple heating layers, which can heat three layers of materials at the same time. The feeding and discharging mechanism adopts high temperature belt conveyor. It has multiple heating modes, which can achieve small footprint, multiple heating areas, and the fastest rhythm can reach 50 seconds/piece.

Mainly used in the production of automotive carpets with thermoplastic materials, multi-layer heating and multi-layer stainless steel mesh belt conveyor.

The line body is mainly composed of a lifting feeding belt conveyor, a heating oven, a conveying mesh belt and a lifting material receiving mechanism.

Multilayer Infrared Heating Furnace: Working Principle

The multilayer infrared heating furnace operates through an integrated automated process that maximizes production efficiency while ensuring uniform material treatment. Here's a detailed breakdown of the working mechanism:

1、Automated Material Feeding Stage

The lifting feeding conveyor automatically positions and transports raw materials (thermoplastic-coated non-woven fabrics) into the heating chamber

Adjustable height mechanism accommodates varying material thicknesses (3-15mm)

Infrared sensors detect material position for precise alignment

2、Multi-Zone Heating Process

Materials enter the 3-layer heating chamber with independently controlled temperature zones:

Pre-heating zone (80-120°C) - initial material softening

Core heating zone (150-200°C) - complete thermoplastic activation

Temperature stabilization zone - ensures even heat distribution

Ceramic infrared emitters provide directional heating with 92-95% energy efficiency

Forced air circulation system prevents hot spots and maintains ±2°C temperature uniformity

3、Multi-Layer Conveyance System

Synchronized stainless steel mesh belts transport materials through each heating zone

Variable speed control (0.5-2m/min) matches material thermal requirements

Anti-sag support system maintains flatness for thick multilayer materials

4、Controlled Discharge Process

Lifting discharge mechanism gently transfers heated materials to forming station

Temperature maintenance system prevents heat loss during transfer

Automatic alignment ensures proper positioning for subsequent pressing

5、Integrated Control System

PLC coordinates all components with production cycle time as fast as 50 seconds

Touchscreen HMI allows parameter adjustment for different material specifications

Energy monitoring system optimizes power consumption in real-time

Key Technical Features

Simultaneous 3-layer processing capacity

30% energy savings vs conventional heating methods

Compact footprint (40% smaller than single-layer systems with equivalent output)

Automatic production data recording for quality tracking