Product Description

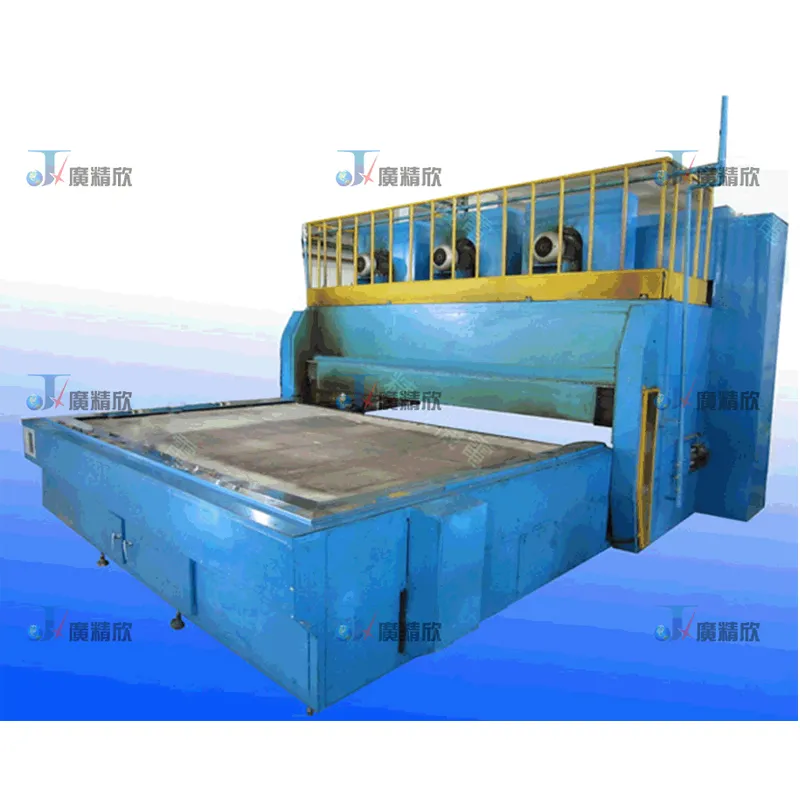

It is mainly used in the production of automotive carpets with thermoplastic materials.

The line body is mainly composed of a base material tray, a heating oven, an interactive chain and other mechanisms.

Working principle: the equipment has two trays to place the substrate, the substrate tray adopts the interactive access mode, and the heating mode adopts the electric heating tube and the air mixing mode. The equipment occupies a small area and is easy to operate. The access is on the same side and only one person is needed to operate.

Product Advantages

✅ Compact and Space-Efficient Design

The oven’s small footprint makes it ideal for installations with space constraints, such as small to medium-sized production lines.

✅ Energy-Efficient Heating

The electric heating tubes combined with air mixing technology allow for efficient energy usage while providing consistent heating across the entire surface area.

✅ Easy Operation

The oven’s design ensures that it is easy to operate with minimal training required. Only one person is needed to load and unload the trays, enhancing the labor efficiency of the production process.

✅ Reduced Operational Costs

With its simple, compact design and easy-to-use functionality, the system helps to reduce operational costs, especially related to labor and floor space.

✅ Consistent and High-Quality Production

The air mixing heating mode ensures that materials are heated uniformly, leading to consistent high-quality results in the production of automotive carpets.

Applications of the Internal Circulating Air Electrically Heating Oven

Automotive Industry

Automotive Carpets: The oven is extensively used in the production of automotive carpets, including floor mats, trunk mats, wheel covers, and seat covers. By ensuring uniform heat distribution, it enhances adhesion and durability of the thermoplastic coating, ensuring the carpets remain durable, heat-resistant, and comfortable under a wide range of environmental conditions.

Interior Components: In addition to carpets, the system can be used for other automotive interior components such as door panels, headliners, and soundproofing materials. These parts often require consistent heating to ensure proper molding and adhesion of thermoplastic materials.

Thermal Insulation: The oven is also used in thermal insulation processes for automotive components, ensuring they meet the necessary heat resistance and durability standards for use in various climate conditions.

Commercial Textile Production

Commercial Carpets and Rugs: The oven is perfect for large-scale production of commercial carpets and rugs, such as those used in hotels, offices, and public spaces. These carpets require a consistent coating of thermoplastic materials for increased durability, heat resistance, and easy cleaning properties.

Wall Coverings and Upholstery: The system can be used in the production of wall coverings and upholstery fabrics, where uniform heating ensures effective bonding of thermoplastic coatings to the substrate material.

Protective Textile Coatings: Ideal for protective textiles used in industrial environments or outdoor settings, where coatings are applied for water resistance, abrasion resistance, and flame retardancy.

Specialty Flooring and Insulation Products

Temporary Event Carpets: For temporary flooring solutions such as event carpets used in exhibitions, trade shows, and conferences, the oven provides quick and efficient processing, ensuring smooth surfaces and high-quality finishes for high-traffic areas.

Soundproofing Materials: The oven is used to create soundproofing materials that require thermoplastic coatings to improve their acoustic properties. These materials are commonly used in commercial buildings, conference rooms, theaters, and even automotive applications.

Insulation Mats: The oven’s consistent heating is ideal for producing thermal and acoustic insulation mats used in both construction and automotive industries to reduce heat loss and external noise.

Aerospace and Transportation

Aircraft Interiors: The oven is useful in the production of non-woven carpets and insulation materials used in aircraft interiors, where lightweight and fire-resistant properties are crucial. The uniform heat provided by the oven ensures that the materials meet aerospace standards for flame resistance and structural integrity.

Railway and Bus Flooring: Similarly, the oven is applied in the manufacturing of railway and bus flooring, ensuring that materials are durable, fire-resistant, and meet safety regulations for public transport vehicles.

Construction and Building Materials

Flooring Materials for Commercial Buildings: The oven can be used to produce thermoplastic-coated flooring materials for commercial and industrial spaces. These floors are designed to be durable, slip-resistant, and easy to clean, making them ideal for hospitals, schools, and shopping malls.

Waterproof Membranes and Roofing Materials: It also plays a role in producing waterproof membranes and roofing materials. The thermoplastic coating applied through the oven ensures that the materials have high water resistance and long-lasting protection against the elements.

Protective Film Coatings: The oven can be used for applying protective films to building materials, such as glass or metal surfaces, to enhance scratch resistance, UV protection, and overall durability.

Sports and Recreation Products

Sports Flooring: The system is used to produce sports flooring materials, such as gym mats, indoor/outdoor courts, and running tracks, where the thermoplastic coating ensures impact resistance, shock absorption, and long-lasting wear in high-traffic environments.

Outdoor Gear and Equipment: The oven can be used for manufacturing various outdoor gear such as tents, tarps, and protective covers. The consistent heating ensures durable, weather-resistant coatings for outdoor activities and harsh environments.

Packaging Materials

Thermoplastic Packaging Films: The oven is beneficial in the production of thermoplastic packaging films used in food packaging, medical packaging, and industrial products. These films require consistent, controlled heating to ensure the adhesion of coatings that protect the contents and enhance shelf life.