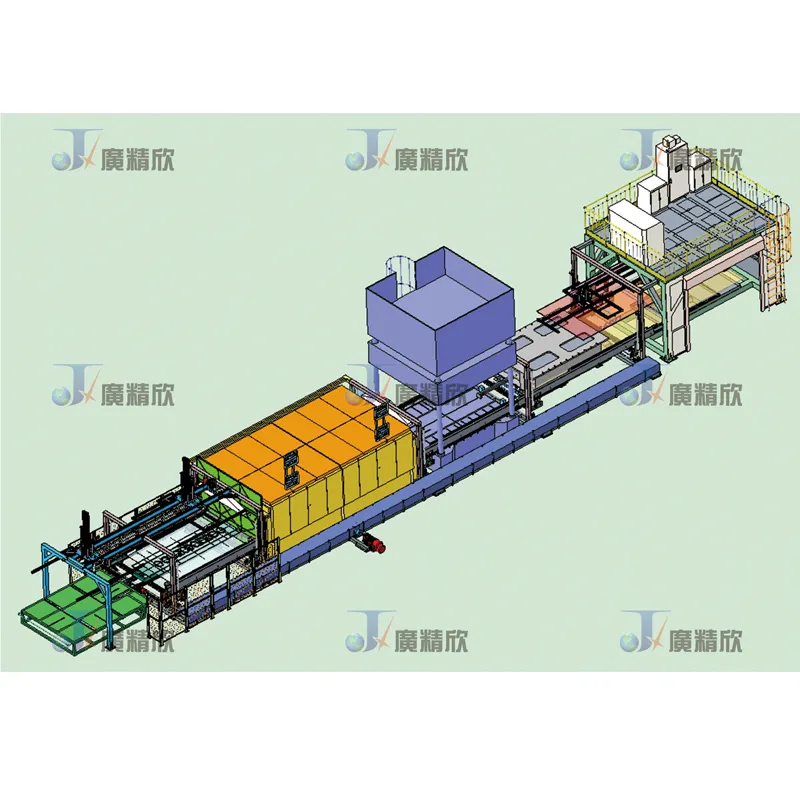

Product Description

Mainly used in the production of blankets (carpets, wheel covers) with thermoplastic material coatings. It is clamped by the gripper jaws on both sides of the girder and heated by the external ceramic heating plate. After forming, the product is automatically clamped and sent to the cutting station for water cutting by the robot.

The line body mainly comprises a sheet material feeding mechanism, a needling mechanism, a net chain conveying mechanism, an oven, a discharging mechanism, high-pressure water cutting and the like.

Expanded Working Principle

1、Material Feeding & Preparation

The process begins with sheet base material feeding using an automated sheet material feeding mechanism.

The needling mechanism enhances the fabric's structure, increasing durability and bonding strength.

2、Heating & Forming

The material is transported via a net chain conveying mechanism to the oven for precise heating.

External ceramic heating plates ensure uniform heating, making the material malleable for forming.

3、Clamping & Forming

The gripper jaws on both sides of the girder securely hold the material in place.

After reaching the desired temperature, the material is pressed into the required shape.

4、Automated Cutting Process

Once formed, the product is automatically clamped and transported to the high-pressure water cutting station.

A robotic water jet cutting system ensures precise trimming with clean edges while minimizing material waste.

5、Final Processing & Discharge

After water cutting, the finished product is discharged automatically for further assembly or packaging.

The fully automated workflow reduces manual handling, ensuring efficiency and consistency.

Applications of the Automobile Carpet Dry Automatic Production Line

Automobile Floor Carpets

Used to manufacture high-durability vehicle carpets with precise shaping and cutting.

Ensures strong adhesion of thermoplastic coatings for better wear resistance.

Wheel Covers & Fender Liners

Produces wheel covers with noise-reducing and protective properties.

Enhances durability and fitment accuracy.

Trunk Mats & Interior Linings

Ideal for trunk carpet production, ensuring proper insulation and durability.

Suitable for cargo liners and floor mats requiring precise forming and cutting.

Automotive Noise & Heat Insulation Components

Can be used for fabricating soundproof and thermal insulation layers for vehicle interiors.

Supports multi-layer composite materials for better performance.