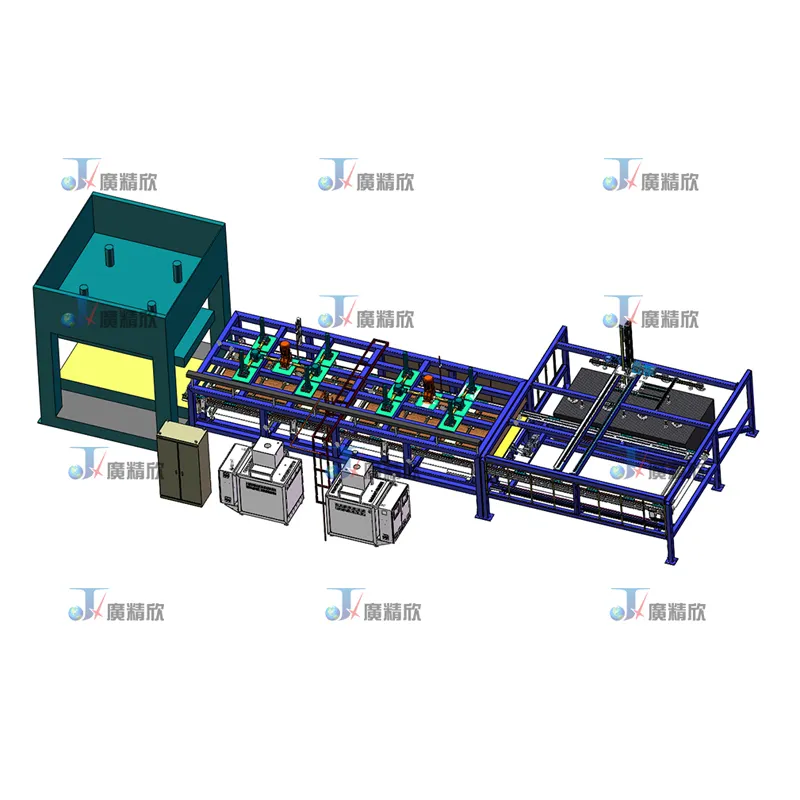

Automotive Carpet Automatic Production Line (Heating By Thermal Conductive Oil)

Product Description

Mainly used to produce non-woven carpet with thermoplastic material coating.

The line body is mainly composed of an automatic feeding mechanism, a Teflon mesh belt, a heating steel template, a forming machine and other mechanisms; Adopt chain conveying and heat conduction oil steel mould heating plate for heating, adopt needle-punched automatic feeding mechanism for feeding, and the width of reclaiming mechanism is adjustable, which can be compatible with different sizes of various products. The heating is controlled by PID mode. In the double oven heating mode, the fastest rhythm can reach 55 seconds/piece. The overall operation of the equipment is simple.

Key Components & Working Principle

(1) Automatic Feeding Mechanism

Needle-Punched Feeding System: Ensures precise alignment and uniform material distribution.

Adjustable Width Mechanism: Compatible with various product sizes (e.g., automotive mats, home carpets).

(2) Conveying System

Teflon-Coated Mesh Belt:

High-temperature resistant & non-stick surface.

Prevents material deformation during heating.

Chain-Driven Conveyor: Ensures smooth, stable, and synchronized material transport.

(3) Heating System

Heat Conduction Oil Steel Template Heating:

Double Heating Plates for uniform temperature distribution.

PID Temperature Control for precise heat regulation (±1°C accuracy).

Energy-efficient & stable compared to electric heating.

(4) Forming Machine

Hydraulic/Pneumatic Cold Press:

High-pressure forming for consistent thickness & texture.

Compatible with embossing rollers for patterned designs.

(5) Control System

PLC + Touchscreen HMI:

Adjustable parameters (speed, temperature, pressure).

Fault detection & alarm system for reduced downtime.

Technical Advantages

✅ High Efficiency: 55 seconds/piece in dual-heating mode.

✅ Energy Saving: Heat conduction oil retains heat longer, reducing power consumption.

✅ Uniform Heating: Steel mold heating eliminates cold spots for consistent quality.

✅ Wide Compatibility: Adjustable for non-woven fabrics, PP, PET, PVC coatings.

✅ Durable Construction: Teflon belt & stainless steel frame for long-term use.

✅ Easy Operation: Automated controls minimize manual intervention.

Applications of Carpet Automatic Production Line

Automotive Carpets: Durable, heat-resistant floor mats.

Home & Office Carpets: Customizable textures/colors.

Industrial Flooring: Anti-slip, heavy-duty mats.

Acoustic Panels: Sound-absorbing non-woven layers.

Why Choose Carpet Automatic Production Line?

Lower operating costs (oil recirculation saves energy).

Superior heat uniformity for defect-free production.

Minimal maintenance (no heating coil replacements).