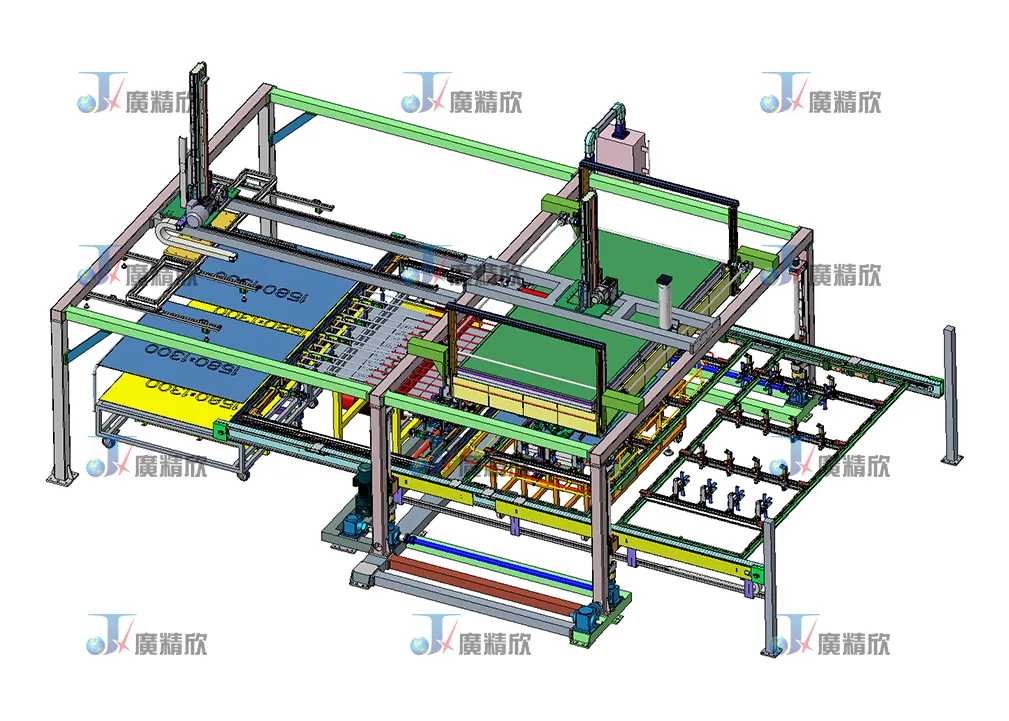

Automatic Feeding Mechanism

The production process begins with the automatic feeding system, which utilizes vacuum suction cups to pick up raw materials. These suction cups are designed to handle various material types and thicknesses, ensuring flexibility in production. The lifting mechanism is driven by a servo motor combined with a planetary gear reducer, providing smooth and precise vertical movement. The multi-speed control feature allows for optimized handling of different material weights and sizes, ensuring stability and minimizing vibration during operation.

Conveying System

The transportation of materials between different stages of production is facilitated by a highly efficient conveying system. The horizontal movement is achieved using a frequency converter-driven synchronous belt mechanism, which ensures quiet and smooth operation. This design minimizes noise pollution in the working environment while maintaining high precision in material positioning. The conveying system is engineered to handle varying loads without compromising speed or accuracy, making it ideal for high-volume production environments.

Infrared Heating System

One of the most critical stages in wheel housing production is the heating process, which ensures the material reaches the optimal temperature for forming. This production line employs an advanced infrared heating system, where the heating tubes are precisely aligned along the mold cavity. This configuration ensures uniform heat distribution and rapid temperature rise, significantly improving energy efficiency compared to traditional heating methods. The infrared heating system is designed to maintain consistent temperatures throughout the production cycle, reducing the risk of material warping or defects.

Forming Mold

The forming mold is a key component that shapes the heated material into the desired wheel housing geometry. The mold is constructed from high-grade materials to withstand prolonged exposure to heat and mechanical stress. Its precision-engineered contours ensure dimensional accuracy and repeatability in every produced part. The mold is integrated with the heating system to maintain optimal forming conditions, allowing for high-quality output with minimal scrap rates.

Unloading Mechanism

Once the wheel housing is formed, the unloading mechanism takes over to remove the finished product from the mold. The extraction process is carried out using a beam conveyor system, which is driven by a frequency converter and a synchronous belt for smooth and quiet operation. The unloading mechanism is equipped with adjustable finger grippers, allowing for secure handling of different product sizes. The clamping force and width of the grippers can be fine-tuned to accommodate various wheel housing dimensions, ensuring compatibility across multiple product variants.

Key Advantages of the Production Line

High Efficiency & Speed – With a cycle time of just 60 seconds per piece, this production line is optimized for high-volume manufacturing, making it ideal for automotive suppliers with demanding production schedules.

Precision & Stability – The integration of servo motors, planetary reducers, and synchronous belt drives ensures precise movement control, reducing deviations and enhancing product consistency.

Energy-Efficient Heating – The infrared heating system provides rapid and uniform heating, reducing energy consumption compared to conventional heating methods.

Flexibility & Adaptability – The adjustable grippers and multi-speed controls allow the line to handle different product sizes and material types without requiring extensive reconfiguration.

Low Noise & Smooth Operation – The use of synchronous belts and frequency converters minimizes mechanical noise, creating a more comfortable working environment.

Applications & Industry Relevance

This wheel housing production line is particularly suited for automotive manufacturers and suppliers specializing in chassis components. Its ability to produce high-precision wheel housings at a rapid pace makes it an invaluable asset for companies looking to enhance their production capabilities while maintaining stringent quality standards. Furthermore, the system’s modular design allows for future upgrades or integration with additional automation solutions, ensuring long-term usability in evolving industrial environments.