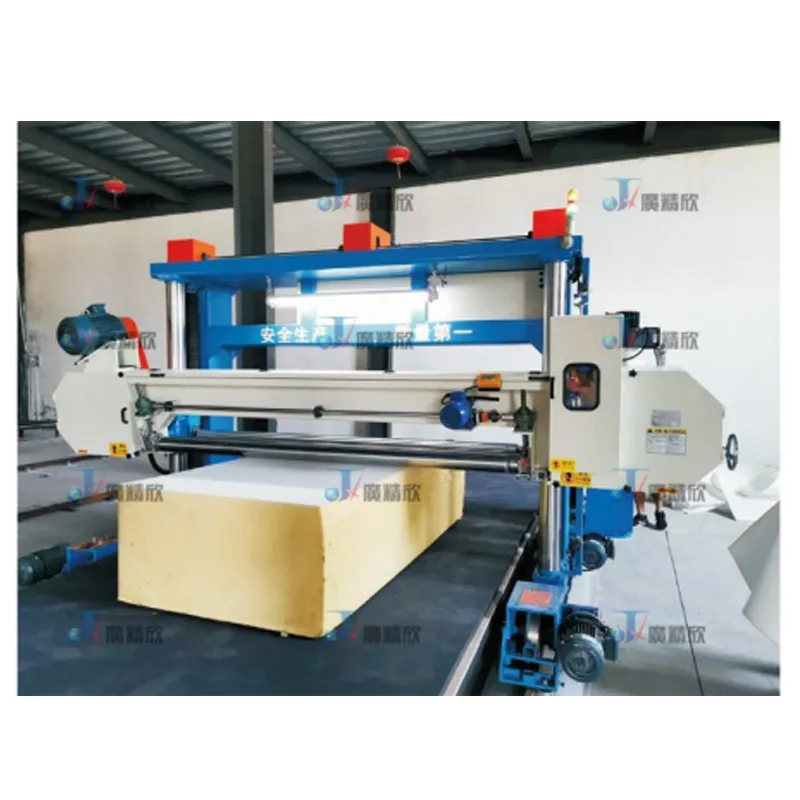

Product Description

Mainly used for slicing PU foam.

The equipment is mainly composed of a cutting system, a translation mechanism and the like; the translation mechanism is driven by a servo system, so that the response speed is high, and the positioning is accurate; the lifting mechanism is driven by a servo system, so that the positioning is accurate; the operation interface is visual, and the operation and the setting are simple and convenient.

Working Principle

The PU Slicer operates through the following key steps:

Material Loading:The PU foam is placed on the slicing platform, where it is securely positioned for cutting.

Automatic Positioning:The servo-driven translation mechanism ensures that the foam is accurately aligned for precise slicing.

Height Adjustment:The lifting mechanism adjusts the cutting blade to the required thickness, ensuring uniform slicing.

Slicing Process:The cutting system moves across the foam, slicing it with high precision and minimal waste.The servo control ensures smooth, vibration-free cutting for clean edges and consistent thickness.

Material Discharge:The sliced foam is automatically transferred to the next processing stage or stacked for further use.

Key Features of the PU Slicer

- 1.High-Precision Cutting System: The slicer is equipped with an advanced cutting system that ensures clean, uniform cuts with minimal material waste. Suitable for cutting various densities of PU foam, including soft, semi-rigid, and high-density foams.

- 2.Servo-Driven Translation Mechanism: The translation mechanism is powered by a servo system, ensuring fast response speed and high positioning accuracy. The system allows for smooth movement, reducing mechanical wear and improving cutting stability.

- 3.Servo-Controlled Lifting Mechanism: The lifting mechanism is also servo-driven, ensuring precise height control for consistent slicing thickness. This feature enables multi-layer cutting, allowing for adjustable foam thickness according to production needs.

- 4.Intuitive Visual Operation Interface: The user-friendly interface provides real-time visual monitoring, allowing operators to easily set and adjust cutting parameters. The simple and efficient controls reduce training time for operators and minimize errors in the production process.

- 5.Customizable Cutting Settings: The equipment supports customized cutting thickness settings, making it suitable for different product specifications. The system can store multiple cutting programs, allowing for quick switching between different product requirements.

Advantages of the PU Slicer

- 1.High Efficiency & Precision: Servo-driven mechanisms ensure fast and accurate positioning, reducing processing time. Produces consistent and high-quality cuts, improving overall product uniformity.

- 2.Customization & Flexibility: Adjustable cutting thickness to meet different production needs.

- Compatible with various PU foam densities for multiple applications.

- 3.Easy Operation & Control: Visual control interface makes parameter adjustments simple and efficient.Operators can quickly switch cutting settings, enhancing production flexibility.

- 4.Reduced Material Waste: The precision cutting system minimizes errors, reducing foam wastage and lowering production costs.

- 5.Stable & Durable Performance: Built with high-quality materials and servo control technology, ensuring long-term reliable operation.Low maintenance requirements, improving overall equipment lifespan.

Applications of the PU Slicer

The PU Slicer is widely used in industries that require precise foam cutting, including:

- 1.Automotive Interior Manufacturing: Cutting PU foam sheets for car seats, ceilings, door panels, and armrests.Ensures uniform thickness and clean cuts for seamless integration into vehicle interiors.

- 2.Furniture Industry: Slicing PU foam for cushions, mattresses, sofas, and padding materials. Produces comfortable, high-quality foam with accurate dimensions.

- 3.Packaging Industry: Cutting foam inserts for protective packaging, ensuring shock absorption and product safety.Ideal for electronics, fragile items, and high-value products.

- 4.Medical & Healthcare Applications: Producing PU foam for orthopedic supports, medical mattresses, and prosthetic padding.Ensures hygienic, precisely cut foam for healthcare needs.

- 5.Industrial & Custom Applications: Used in insulation, sports equipment, aerospace, and soundproofing foam manufacturing.Allows for customized foam sizes and shapes for diverse applications.

Why Choose the PU Slicer?

The PU Slicer is an essential machine for industries requiring high-precision polyurethane foam cutting. Its servo-driven translation and lifting mechanisms, user-friendly operation, and customizable cutting options make it a highly efficient and versatile solution. With its ability to deliver consistent quality, minimize waste, and enhance production efficiency, the PU Slicer is the ideal choice for manufacturers in automotive interiors, furniture, packaging, and beyond.