Automobile Headliner Wet Method Line (Fiberglass Rolling Adhesive Process)

Product Description

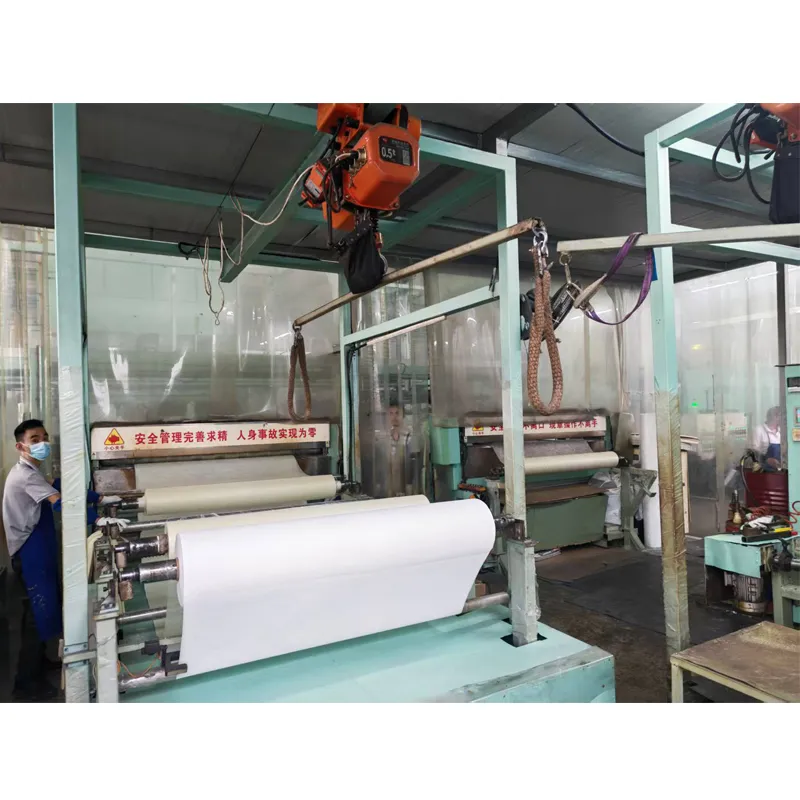

Mainly used for automobile interior headliner made by rolling glass fiber felt, spraying PU plate, overlapping with upper and lower non-woven fabrics, and pressing by forming press.

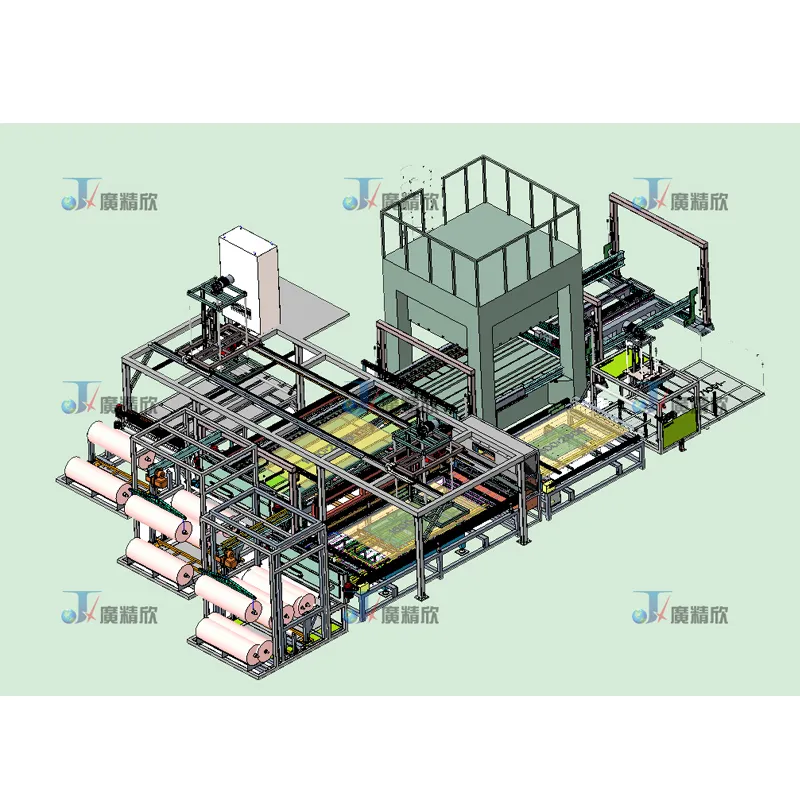

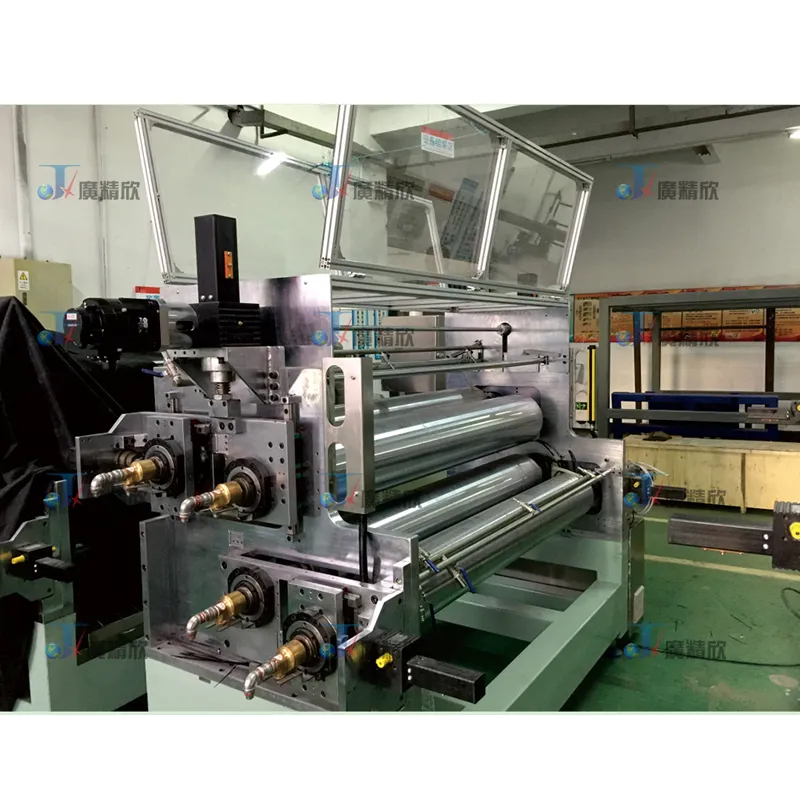

The production line is mainly composed of a PU feeding machine, a glass fiber glue rolling machine, a pre-spraying conveying machine, a spraying machine, a post-spraying conveying machine, a coil material feeding machine, a cutting machine, a transfer machine, a feeding mechanism, a discharging mechanism and the like;

Working principle: the process of PU upper and lower layers of glass fiber felt rolling glue and PU plate spraying is adopted. The PU lower layer is made of non-woven fabric and glass fiber felt. After five layers of materials are superimposed, they are sent to the forming machine in the form of conveying beam. After forming and pressure maintaining, the finished product is taken out by the reclaiming gripper and sent to the manual reclaiming post or the subsequent process.

Key Features & Advantages

Automated & High-Efficiency Production

This production line is fully automated, significantly reducing manual labor and improving production accuracy. The combination of glass fiber felt rolling glue application and PU plate spraying ensures strong adhesion and structural integrity, enhancing the headliner's durability and sound insulation performance.

Optimized Cost Savings

Labor Efficiency: Requires only 1-2 operators, saving 4-5 workers compared to traditional manual production.

Material Utilization: The precise cutting system reduces material waste by minimizing clamping distance, leading to lower production costs.

Fast Production Cycle: The system achieves a high-speed rhythm of up to 62 seconds per piece, ensuring efficient large-scale manufacturing.

Advanced Functional Integration

The production line can be equipped with specialized modules to enhance functionality, including:

Glass fiber reinforcement placement mechanism, ensuring additional strength.

Non-woven fabric positioning system, maintaining accurate material alignment.

Ultrasonic warning label system, improving safety and quality control.

Intelligent Management System

By integrating with the MAS management monitoring system, the production line enables:

Real-time production monitoring for increased transparency.

Material scanning error prevention to eliminate processing errors.

Visual management system for better workflow optimization.