Product Description

Mainly used to produce non-woven carpet with thermoplastic material coating.

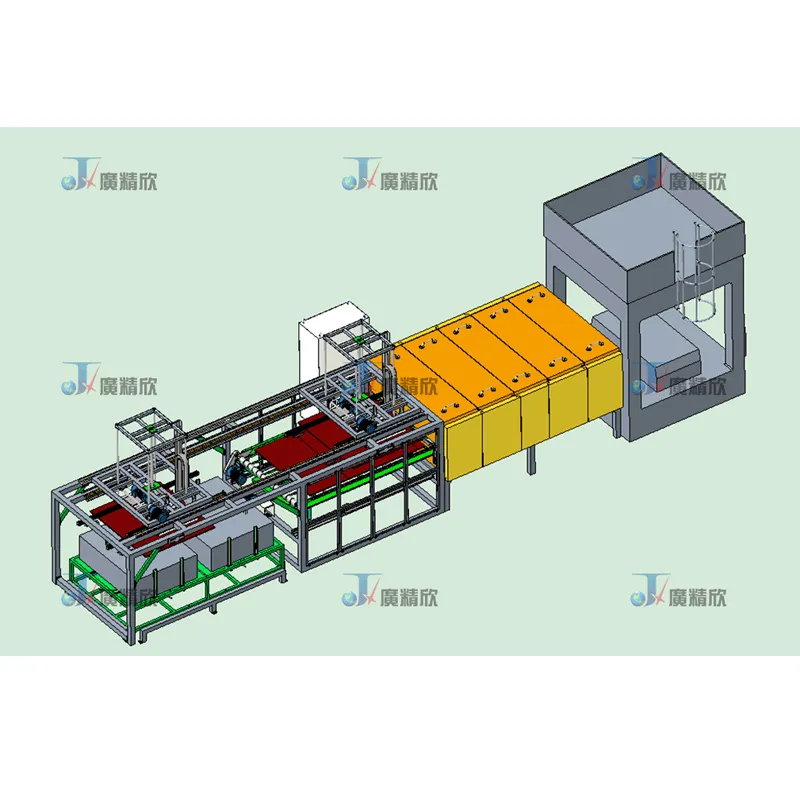

The line body is mainly composed of an automatic feeding mechanism, a conveying mesh belt, an oven, a forming machine and the like; The equipment adopts stainless steel mesh belt to convey, adopts infrared ceramic oven to heat the carpet substrate, adopts needle-punched automatic feeding mechanism, and the width of the material taking mechanism is adjustable, which can be compatible with different sizes of various products. In the double oven heating mode, the speed can be up to 55 seconds/piece.

Key Components & Functions

(1) Automatic Feeding Mechanism

Needle-Punched Feeding System: Ensures precise material placement for uniform carpet production.

Adjustable Width Compatibility: The material-taking mechanism can be adjusted to accommodate different product sizes, enhancing flexibility.

(2) Conveying System

Stainless Steel Mesh Belt: Provides high-temperature resistance, durability, and smooth transportation without material deformation.

Anti-Slip & Tension Control: Prevents misalignment and ensures consistent movement through the production stages.

(3) Infrared Ceramic Oven

Dual-Oven Heating System: Ensures rapid and uniform heating of the non-woven carpet substrate and thermoplastic coating.

Energy-Efficient Heating: Infrared ceramic heating reduces power consumption compared to conventional hot air ovens.

Precise Temperature Control: Adjustable heating zones for optimal material softening without overheating.

(4) Forming Machine

Cold Press or Thermoforming Options: Depending on the carpet design, the machine can press or mold the heated material into the desired shape.

High-Pressure Stability: Ensures consistent thickness and texture across the entire carpet surface.

(5) Control System

PLC & Touchscreen Interface: Allows easy adjustment of temperature, speed, and pressure for different production requirements.

Automated Speed Synchronization: The conveyor, oven, and forming machine work in sync for seamless operation.

Technical Advantages

High Production Speed: With dual-oven heating, the line achieves a cycle time of 55 seconds/piece, maximizing output.

Energy Savings: Infrared ceramic heating is 30-40% more efficient than traditional heating methods.

Material Versatility: Compatible with non-woven fabrics, thermoplastic polymers (PP, PET, PVC), and composite materials.

Adjustable Width: The feeding and forming mechanisms can be modified for different carpet sizes (e.g., automotive mats, home carpets, industrial flooring).

Consistent Quality: Uniform heating and precise pressure control prevent defects like uneven thickness or weak bonding.

Low Maintenance: Stainless steel construction and durable components reduce downtime and repair costs.

Automatic Carpet Production Line is Ideal for Manufacturing

Automotive Carpets & Floor Mats: Lightweight, durable, and customizable for car interiors.

Home & Office Carpets: Non-woven, eco-friendly carpets with thermoplastic backing for enhanced durability.

Industrial & Commercial Flooring: High-strength, anti-slip mats for factories, gyms, and public spaces.

Decorative & Acoustic Panels: Textured surfaces for wall coverings or soundproofing applications.

Why Choose This Automatic Carpet Production Line?

This fully automated, infrared-heated carpet production line offers speed, precision, and cost-efficiency, making it a superior choice for manufacturers looking to increase output while reducing energy consumption. Its adjustable design ensures compatibility with various materials and product dimensions, providing long-term flexibility for evolving market demands.