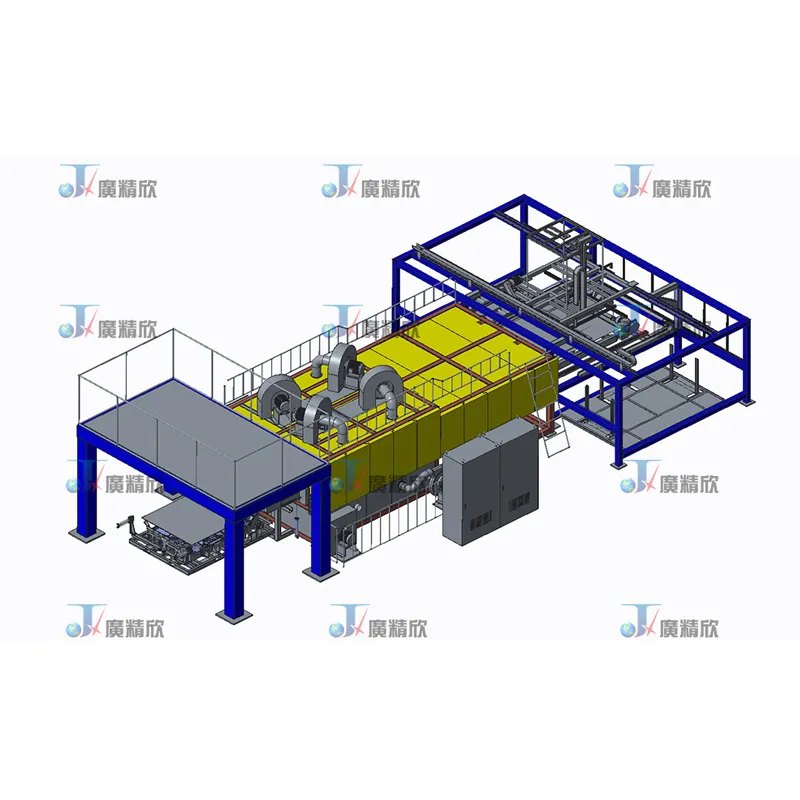

Product Description

Mainly used to produce non-woven carpet with thermoplastic material coating.

The line body is mainly composed of an automatic feeding mechanism, a Teflon mesh belt, an air mixing heating mechanism, a forming machine and the like; It adopts stainless steel mesh and Teflon mesh belt for conveying, adopts air mixing penetration heating mode, adopts needle-punched automatic feeding mechanism for feeding, and the width of the reclaiming mechanism is adjustable, which can be compatible with different sizes of various products. The heating is controlled by mixed air up and down penetration and PID mode. Under the double oven heating mode, the fastest rhythm can reach 55 seconds/piece.

Working Principle

1、Automated Material Feeding

The process begins with an automatic needle-punched feeding mechanism, which accurately delivers raw materials to the production line.

The feeding system is adaptable to various material types and sizes, ensuring flexibility in manufacturing.

2、Conveying & Heating System

The material is transported using stainless steel and Teflon mesh belts, ensuring smooth movement and high-temperature resistance.

The system utilizes an air mixing penetration heating method, which enables even and deep heat penetration, ensuring optimal bonding of thermoplastic coatings.

The PID-controlled heating maintains stable temperature regulation, preventing overheating or underheating.

3、Forming & Shaping

After the heating process, the material enters the forming machine, where the non-woven carpet is shaped according to the required specifications.

The adjustable reclaiming mechanism width allows for compatibility with different product sizes, enhancing production flexibility.

4、Dual-Oven Heating for High-Speed Production

The system is equipped with a double-oven heating mode, allowing for faster processing times.

With an optimized production rhythm, the system achieves up to 55 seconds per piece, significantly boosting manufacturing efficiency.

Product Advantages

✅ Efficient & High-Speed Production

The dual-oven heating and optimized air mixing penetration ensure fast and uniform heating, achieving a production speed of 55 seconds per piece.

✅ Superior Heating & Material Bonding

The air mixing penetration heating mode allows deep and even heat distribution, resulting in stronger material bonding and durability.

PID temperature control maintains stable and precise heating, preventing defects.

✅ Versatile & Adjustable Production Line

The adjustable reclaiming width ensures compatibility with various carpet sizes, making it suitable for different product specifications.

The automatic needle-punched feeding system allows for the processing of multiple material types, increasing production flexibility.

✅ Durable & High-Quality Construction

The stainless steel and Teflon mesh belts provide high-temperature resistance, ensuring long-term durability.

The precision-controlled forming process enhances final product consistency and quality.

Applications of the Automatic Carpet Production Line

This production line is widely used in various industries for manufacturing non-woven carpets with thermoplastic coatings, ensuring high durability, precise formation, and superior performance.

✅ Automotive Industry

Car floor carpets, trunk mats, and wheel covers with thermoplastic coatings.

Enhances durability, heat resistance, and sound insulation in vehicle interiors.

✅ Commercial & Residential Carpets

Non-woven carpets for offices, hotels, and homes, providing wear resistance and easy maintenance.

Suitable for custom-sized carpets with precise cutting and shaping.

✅ Industrial & Special-Purpose Flooring

Used in factories, exhibition halls, and commercial spaces requiring durable and heat-resistant carpets.

Ideal for temporary event flooring and protective underlayers.

✅ Aerospace & Public Transportation

Suitable for airplane, train, and bus floor carpets, ensuring high-quality, lightweight, and fire-resistant material performance.