Product Description

Compared with the traditional glue spraying process, the fabric glue rolling process is more economical and environmentally friendly.

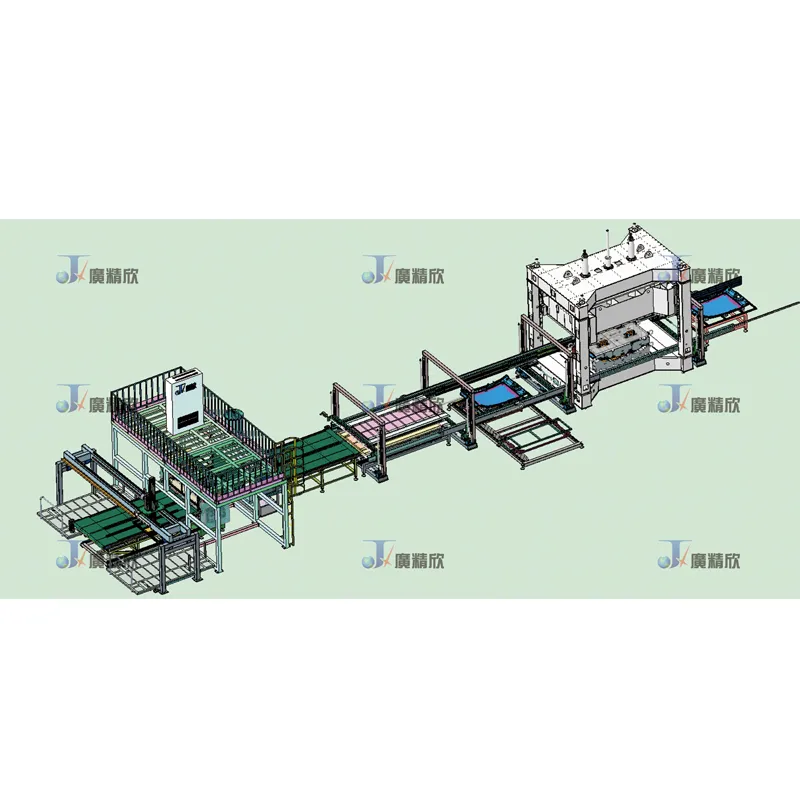

The line body is mainly composed of a feeding machine, a glue rolling machine, a spraying machine, a conveying belt, a reverse throwing mechanism and the like.

Working principle: adopt the process of fabric glue rolling and spraying, throw it back to the surface of the headliner framework, and put it into the forming machine manually for fitting and forming.

Key Features & Advantages

Eco-Friendly & Cost-Effective

Reduces glue consumption, minimizing emissions and waste.

Compared to traditional glue spraying, this method is more precise, reducing excess adhesive use.

Lower operational costs with optimized material utilization.

Efficient & Streamlined Production

The line is designed for seamless integration into automotive interior manufacturing, featuring:

Automated feeding machine for continuous material input.

Precision glue rolling machine ensuring uniform adhesive application.

Controlled spraying machine for enhanced bonding efficiency.

Conveying belt and reverse throwing mechanism for smooth material handling.

Simplified Process & Strong Adhesion

Fabric glue rolling and spraying is applied to the material surface.

The adhesive-coated fabric is thrown back onto the surface of the headliner framework using the reverse throwing mechanism.

The assembled components are manually placed into the forming machine for fitting and shaping.

Applications of the Fabric Rolling Glue Line

Automotive headliner Linings

Used for attaching fabric materials to vehicle headliners with high precision and strong bonding.

Ensures a smooth, uniform surface while reducing glue consumption.

Door Panel Fabric Bonding

Provides secure adhesion for fabric layers on car door panels, improving durability and appearance.

Reduces the risk of fabric peeling or detachment over time.

Dashboard & Interior Trim Components

Helps in bonding fabric materials to dashboards, side panels, and center consoles.

Ensures aesthetic consistency and long-lasting adhesion in high-touch areas.

Seat Upholstery & Armrests

Used for coating and attaching fabric layers in seats, headrests, and armrests.

Enhances comfort, durability, and visual appeal.

Sun Visors & Pillar Covers

Assists in fabric application on sun visors and interior pillar covers, ensuring neat finishing and strong adhesion.

Advantages in Application

Suitable for various fabric types, including woven, non-woven, and synthetic materials.

Supports high-volume production with consistent quality.

Minimizes environmental impact compared to traditional glue spraying methods.