Robotic High-Pressure Waterjet Cutting - Chongqing Guang Jingxin Technology Co., Ltd.|Precision, Efficiency, Automotive Manufacturing

Robotic High-Pressure Waterjet Cutting - Chongqing Guang Jingxin Technology Co., Ltd.|Precision, Efficiency, Automotive Manufacturing

In the rapidly evolving automotive industry, precision and efficiency are non-negotiable. Robotic High-Pressure Waterjet Cutting systems have emerged as a revolutionary solution, addressing the complex demands of modern manufacturing. This article delves into the technology, applications, and advantages of this advanced system, highlighting its role in shaping the future of automotive production.

Product Overview

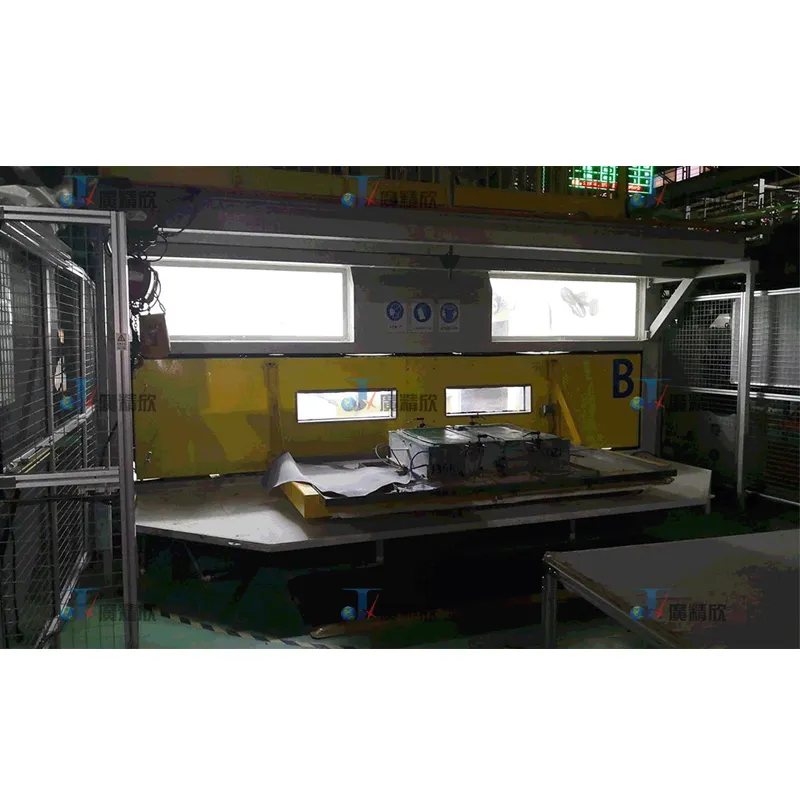

The Robotic High-Pressure Waterjet Cutting System is a cutting-edge solution designed for precision cutting of automotive interior parts. Equipped with a 6-axis robot and a high-pressure waterjet system, this technology enables the accurate creation of intricate shapes and holes, such as positioning holes, skylight holes, and handle holes. The system's unique upside-down structure with multiple robots ensures a compact footprint, maximizing space efficiency while maintaining high productivity. With a fastest cycle time of 55 seconds per piece, it meets the rigorous demands of modern automotive manufacturing.

Read More About waterjet cutting machine price list

Working Principle

The system integrates a 6-axis robot with a high-pressure waterjet cutting mechanism, allowing for precise and efficient cutting of automotive interior materials such as plastics, foams, fabrics, and composites. The high-pressure waterjet technique ensures clean, smooth cuts with minimal material waste, eliminating the risk of heat distortion. This process is supported by product positioning molds that guarantee accurate alignment of parts during cutting, ensuring consistency and reproducibility.

Key Components

- 6-Axis Robot: Provides multi-directional movement for intricate cuts.

- High-Pressure Waterjet System: Delivers precise, clean cuts with minimal material deformation.

- Product Positioning Moulds: Ensure accurate alignment and reproducibility.

Key Advantages

The Robotic High-Pressure Waterjet Cutting System offers several advantages that make it a preferred choice for automotive manufacturers:

- High Precision: The combination of a 6-axis robot and high-pressure waterjet ensures accurate cuts for complex shapes and holes.

- Minimal Material Waste: The waterjet process reduces heat generation and kerf width, minimizing material loss.

- Increased Efficiency: Multiple robots working in coordination achieve a cycle time of 55 seconds per piece.

- Compact and Flexible Design: The upside-down structure saves space and allows adaptation to various interior parts.

- Enhanced Quality Control: Precise cuts and positioning molds ensure consistent quality and reduced rework.

Read More About water jet machine

Applications

This system is widely used in the automotive industry for cutting interior components. Its versatility allows it to handle a variety of materials, including plastics, foams, fabrics, and composites. Key applications include:

- Automotive Interior Parts: Dashboard panels, door trim, seating parts, and headliners.

- Complex Shape Cutting: Skylight holes, handle holes, ventilation openings, and accessory mounting points.

- Electric Vehicle (EV) Components: Precision cutting for electrical systems, battery enclosures, and lightweight panels.

- Prototyping and Low-Volume Production: Quick setup and flexibility for new design development.

Product Specifications

| Specification | Details |

|---|---|

| Robot Type | 6-Axis Robot |

| Waterjet Pressure | High-Pressure (varies by model) |

| Cycle Time | Up to 55 seconds per piece |

| Materials Supported | Plastics, foams, fabrics, composites |

| Positioning System | Product Positioning Moulds |

| Space Efficiency | Upside-Down Structure with Multiple Robots |

Company Background

The Robotic High-Pressure Waterjet Cutting System is developed by Chongqing Guang Jingxin Technology Co., Ltd., a leading manufacturer specializing in advanced manufacturing solutions. With a focus on innovation and quality, the company has established itself as a trusted partner for automotive manufacturers seeking efficient and precise cutting technologies.

Why Choose This System?

For automotive manufacturers, the Robotic High-Pressure Waterjet Cutting System offers a competitive edge through its combination of precision, efficiency, and flexibility. Its ability to handle complex shapes and materials while minimizing waste makes it an ideal solution for both traditional and electric vehicle production. As the automotive industry continues to evolve, this technology ensures manufacturers can meet the demands of modern manufacturing with consistent quality and cost-effectiveness.

Industry Standards and Authority

The development and implementation of advanced manufacturing technologies like the Robotic High-Pressure Waterjet Cutting System are supported by rigorous industry standards. Organizations such as the National Institute of Standards and Technology (NIST) play a critical role in establishing benchmarks for precision and quality in manufacturing processes. NIST's research and standards ensure that technologies like waterjet cutting meet the highest levels of accuracy and reliability, contributing to the advancement of the automotive industry.

Reference

National Institute of Standards and Technology (NIST) provides critical support for manufacturing innovation through its research and standards development. Their work ensures that technologies like high-pressure waterjet cutting maintain the precision and efficiency required for modern automotive production.

Conclusion

The Robotic High-Pressure Waterjet Cutting System represents a significant advancement in automotive manufacturing. By combining robotic precision with high-pressure waterjet technology, it offers unparalleled efficiency, accuracy, and flexibility. As the industry continues to prioritize innovation and sustainability, this system stands out as a reliable solution for meeting the challenges of modern production. For manufacturers looking to enhance their operations, the Robotic High-Pressure Waterjet Cutting System is an investment in the future of automotive manufacturing.