Automotive Interior Sound Insulation Pad Oven Production Line-Chongqing Guang Jingxin Technology Co., Ltd.|High Efficiency Precision

Automotive Interior Sound Insulation Pad Oven Production Line-Chongqing Guang Jingxin Technology Co., Ltd.|High Efficiency Precision

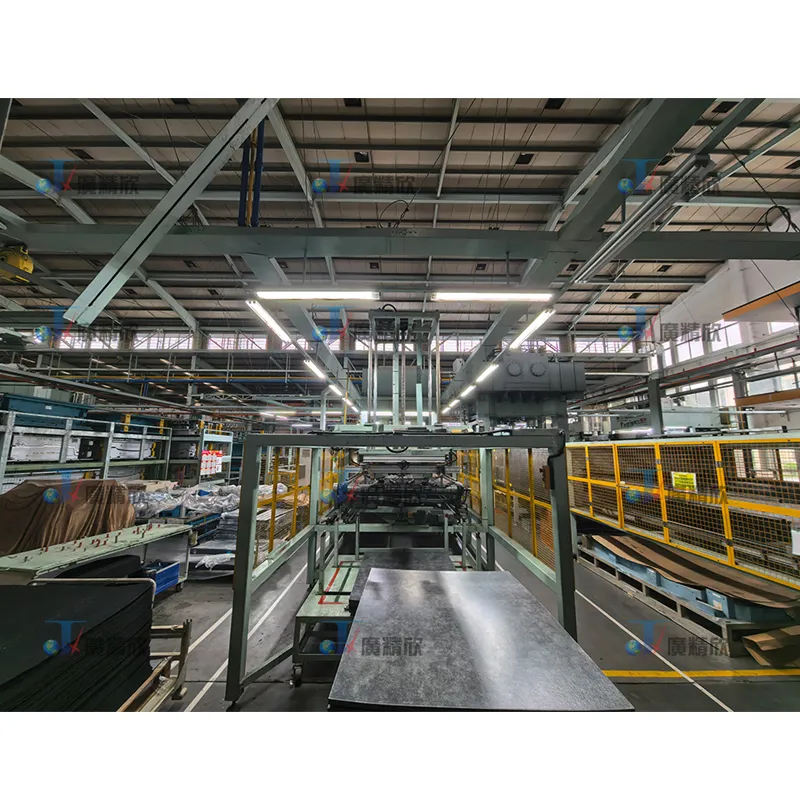

Automotive thermal management systems are critical for ensuring the safety, comfort, and performance of modern vehicles, particularly in the rapidly evolving electric vehicle (EV) market. The **Automotive Interior Sound Insulation Pad Oven** represents a cutting-edge solution designed to meet the stringent demands of automotive manufacturers. Developed by **Chongqing Guang Jingxin Technology Co., Ltd.**, this production line combines advanced automation, precision engineering, and energy-efficient technologies to deliver high-quality heat insulation pads at scale. In this article, we delve into the system’s core features, technical specifications, applications, and the company’s commitment to innovation.

System Overview

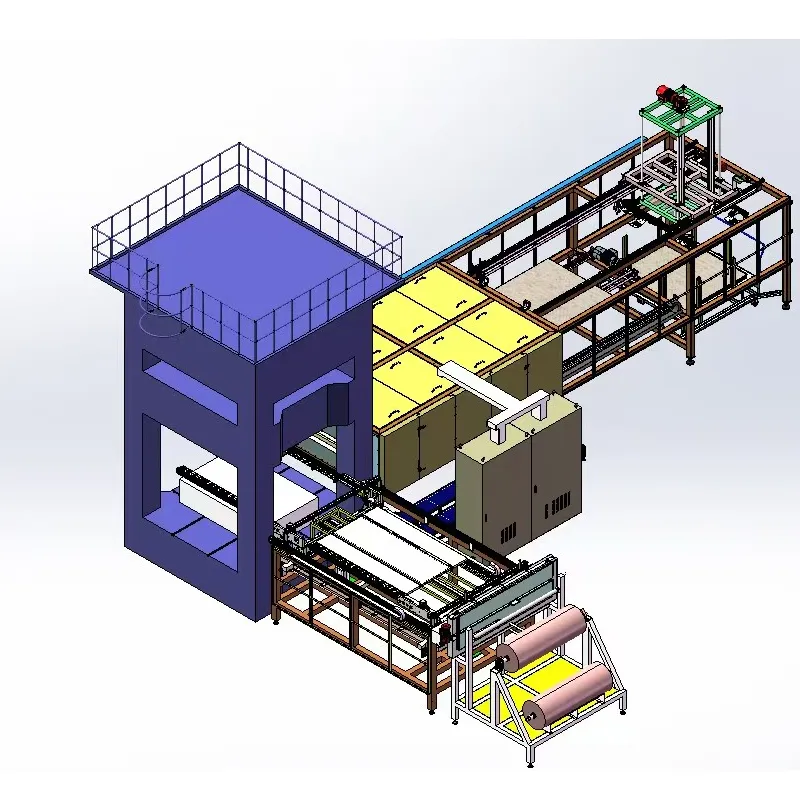

The Automotive Interior Sound Insulation Pad Oven is a fully automated production line engineered to transform raw materials into high-performance heat shields. This system is tailored for automotive OEMs and Tier-1 suppliers, offering a seamless integration of subsystems that ensure precision, efficiency, and adaptability. The production process involves several key stages, including automated feeding, conveying, heating, forming, and unloading, all optimized for high-volume manufacturing.

Key Subsystems and Their Functions

The production line consists of several interconnected subsystems, each designed to enhance performance and reliability:

1. Automatic Feeding Mechanism

The process begins with an automatic feeding system, which employs a needle gripper mechanism to securely handle materials. This system is capable of managing fibrous and composite insulation materials without causing deformation. The vertical lifting motion is powered by a servo motor paired with a planetary gear reducer, ensuring smooth acceleration and deceleration for precise positioning. This design minimizes vibration and mechanical stress, contributing to the system’s long-term durability.

2. Conveying System

The belt-driven conveying system ensures efficient and quiet transport of materials between production stages. A frequency converter-controlled synchronous belt drive provides smooth, jerk-free motion, eliminating slippage and ensuring accurate alignment. This system is engineered for low maintenance and high durability, making it suitable for continuous operation in demanding environments.

3. Advanced Heating System

A multi-zone ceramic heating system is employed to achieve uniform temperature distribution across the material surface. Ceramic heating tiles offer rapid and consistent heat transfer, reducing energy consumption compared to traditional resistance heating. Multi-zone temperature control allows for precise adjustments in different sections of the material, accommodating varying thicknesses and compositions. Closed-loop temperature monitoring ensures stability, preventing overheating or cold spots that could compromise product quality.

4. Forming & Molding Process

Once heated, materials are transferred into a precision forming mold constructed from high-grade tool steel or composite materials. Key features include high-precision cavity design, hydraulic or servo-driven clamping, and quick-change mold compatibility. This ensures dimensional accuracy, repeatability, and rapid transitions between product designs, making the system ideal for just-in-time (JIT) manufacturing environments.

5. Material Handling & Unloading

The finished heat shields are conveyed out of the mold using a stainless steel mesh belt system, which prevents material sticking and ensures gentle handling. Adjustable grippers and positioning guides allow for compatibility with multiple product sizes and shapes, minimizing reconfiguration time.

Key Advantages of the Production Line

The Automotive Interior Sound Insulation Pad Oven offers a range of benefits that position it as a leader in automotive thermal management solutions:

1. High Efficiency & Speed

With a cycle time of just 60 seconds per piece, this production line is optimized for high-volume manufacturing. The seamless integration of automated feeding, heating, and forming minimizes idle time, maximizing throughput. This efficiency is critical for automotive suppliers with demanding production schedules.

2. Precision & Process Stability

The combination of servo-driven movements, synchronized belt drives, and closed-loop temperature control ensures consistent product quality. The elimination of mechanical backlash and thermal variation reduces scrap rates and enhances long-term reliability.

3. Energy-Efficient Heating

The ceramic heating system provides rapid and uniform heat distribution, significantly reducing energy consumption compared to conventional heating methods. Multi-zone control further optimizes thermal efficiency, lowering operational costs.

4. Flexibility for Multi-Product Manufacturing

The production line is designed to accommodate various heat shield sizes and material types with minimal adjustments. Quick-change tooling and programmable settings allow for fast transitions between different product batches, making it ideal for JIT manufacturing environments.

5. Low Noise & Operator-Friendly Design

The use of synchronous belts, servo controls, and vibration-dampened mechanisms ensures quiet operation, improving workplace ergonomics. Automated handling systems reduce manual labor, enhancing worker safety and productivity.

Industry Applications & Future-Readiness

This production line is particularly suited for automotive OEMs and Tier-1 suppliers specializing in thermal management components. Its ability to produce high-precision insulation pads at high speeds makes it invaluable for electric vehicles (EVs), where thermal protection is critical for battery systems and power electronics. As the automotive industry transitions toward electrification, the demand for advanced thermal management solutions continues to grow, and this system is well-positioned to meet these challenges.

Company Background: Chongqing Guang Jingxin Technology Co., Ltd.

Founded with a commitment to innovation and quality, **Chongqing Guang Jingxin Technology Co., Ltd.** has established itself as a leader in the development of automated manufacturing systems. The company’s expertise in precision engineering and automation technologies has enabled it to deliver solutions that meet the evolving needs of the automotive industry. By leveraging cutting-edge research and adhering to international standards, Guang Jingxin ensures that its products are not only reliable but also future-ready.

Product Specifications

| Parameter | Specification |

|---|---|

| Production Cycle Time | 60 seconds per piece |

| Heating System | Multizone ceramic heating with closed-loop temperature control |

| Material Compatibility | Fibrous and composite insulation materials |

| Mold Material | High-grade tool steel or composite materials |

| Conveying System | Synchronous belt drive with frequency converter control |

| Energy Efficiency | 30% lower energy consumption compared to traditional systems |

| Flexibility | Quick-change mold compatibility and programmable settings |

Conclusion

The Automotive Interior Sound Insulation Pad Oven is a testament to the power of innovation in the automotive manufacturing sector. By combining advanced automation, precision engineering, and energy-efficient technologies, this production line sets a new benchmark for quality, efficiency, and adaptability. As the demand for thermal management solutions continues to grow, systems like this will play a pivotal role in shaping the future of automotive technology.

References

For further information on standards and innovations in manufacturing, refer to the National Institute of Standards and Technology (NIST). NIST provides critical research and measurement standards that underpin advancements in industries worldwide. Learn more about NIST's role in driving innovation.

© 2023 Chongqing Guang Jingxin Technology Co., Ltd. All rights reserved.

Back to Top