Automotive Carpet Production Line - Chongqing Guang Jingxin|High-Speed Heating&Adjustable Width

Automotive Carpet Production Line - Chongqing Guang Jingxin|High-Speed Heating&Adjustable Width

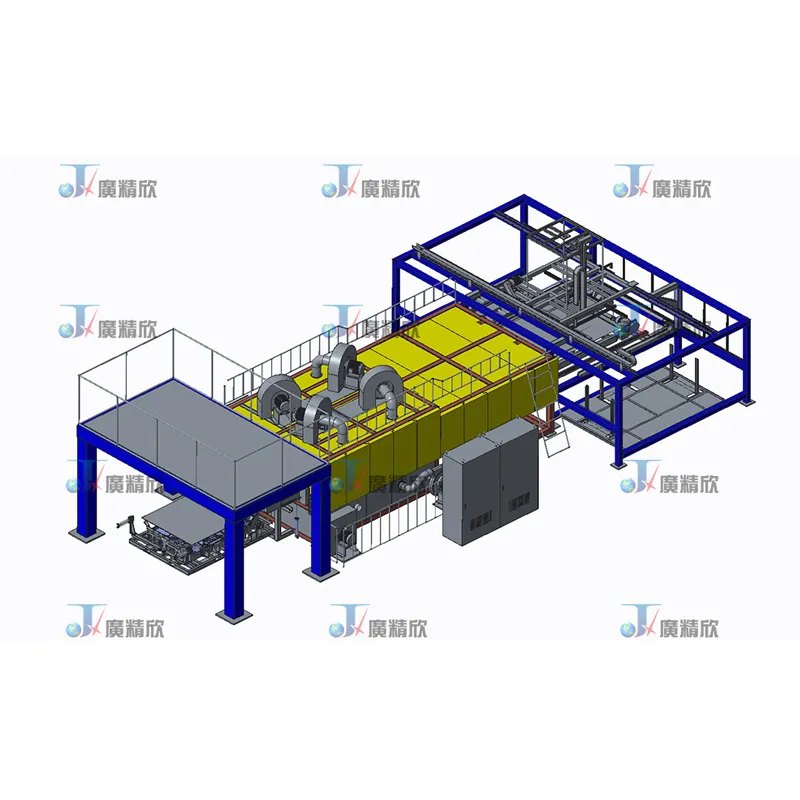

The Automotive Carpet Production Line is a cutting-edge manufacturing solution designed to produce non-woven carpets with thermoplastic material coatings. Developed by Chongqing Guang Jingxin Technology Co., Ltd., this system combines advanced engineering with precision control to deliver high-quality, durable automotive carpets. Below is a comprehensive overview of its features, applications, and technical specifications.

Product Description

The Automotive Carpet Production Line is engineered to streamline the manufacturing of non-woven carpets with thermoplastic coatings. This system is particularly suited for automotive applications, where durability, heat resistance, and sound insulation are critical. The production line integrates multiple components, including an automatic feeding mechanism, Teflon mesh belts, an air mixing heating system, and a forming machine, to ensure efficient and precise output.

Read More About carpet manufacturing machine

Working Principle

The production line operates through a series of interconnected processes that ensure optimal material bonding and shaping. Here’s a breakdown of its key steps:

1. Automated Material Feeding

The process begins with an automatic needle-punched feeding mechanism, which precisely delivers raw materials to the production line. This system is adaptable to various material types and sizes, offering flexibility in manufacturing. The needle-punched feeding mechanism ensures consistent material supply, reducing waste and improving efficiency.

2. Conveying & Heating System

The material is transported using stainless steel and Teflon mesh belts, which provide high-temperature resistance and smooth movement. The system employs an air mixing penetration heating mode, enabling even and deep heat distribution. This method ensures optimal bonding of thermoplastic coatings, enhancing the product’s durability. The PID-controlled heating system maintains stable temperature regulation, preventing overheating or underheating.

Read More About carpet making equipment

3. Forming & Shaping

After the heating process, the material enters the forming machine, where the non-woven carpet is shaped according to the required specifications. The adjustable reclaiming mechanism width allows compatibility with different product sizes, enhancing production flexibility. This adaptability ensures the system can handle various carpet dimensions, making it suitable for diverse applications.

4. Dual-Oven Heating for High-Speed Production

The system features a dual-oven heating mode, which significantly boosts processing speed. With an optimized production rhythm, the system achieves up to 55 seconds per piece, making it ideal for high-volume manufacturing. This rapid cycle time ensures efficient production without compromising quality.

Read More About carpet manufacturing machine price

Product Advantages

The Automotive Carpet Production Line offers several key advantages that set it apart from traditional manufacturing systems:

- Efficient & High-Speed Production: The dual-oven heating and optimized air mixing penetration ensure fast and uniform heating, achieving a production speed of 55 seconds per piece.

- Superior Heating & Material Bonding: The air mixing penetration heating mode allows deep and even heat distribution, resulting in stronger material bonding and durability. PID temperature control maintains stable and precise heating, preventing defects.

- Versatile & Adjustable Production Line: The adjustable reclaiming width ensures compatibility with various carpet sizes, making it suitable for different product specifications. The automatic needle-punched feeding system allows for the processing of multiple material types, increasing production flexibility.

- Durable & High-Quality Construction: The stainless steel and Teflon mesh belts provide high-temperature resistance, ensuring long-term durability. The precision-controlled forming process enhances final product consistency and quality.

Applications of the Automotive Carpet Production Line

This production line is widely used in various industries for manufacturing non-woven carpets with thermoplastic coatings. Key applications include:

✅ Automotive Industry

Car floor carpets, trunk mats, and wheel covers with thermoplastic coatings. Enhances durability, heat resistance, and sound insulation in vehicle interiors.

✅ Commercial & Residential Carpets

Non-woven carpets for offices, hotels, and homes, providing wear resistance and easy maintenance. Suitable for custom-sized carpets with precise cutting and shaping.

✅ Industrial & Special-Purpose Flooring

Used in factories, exhibition halls, and commercial spaces requiring durable and heat-resistant carpets. Ideal for temporary event flooring and protective underlayers.

✅ Aerospace & Public Transportation

Suitable for airplane, train, and bus floor carpets, ensuring high-quality, lightweight, and fire-resistant material performance.

Company Background

Chongqing Guang Jingxin Technology Co., Ltd. is a leading manufacturer of industrial production equipment, specializing in innovative solutions for the textile and automotive industries. With a focus on precision engineering and advanced automation, the company has established itself as a trusted partner for manufacturers worldwide. Their commitment to quality, reliability, and customer satisfaction has driven the development of the Automotive Carpet Production Line, which exemplifies their dedication to excellence in manufacturing technology.

Product Specifications

| Feature | Specification |

|---|---|

| Heating Method | Air Mixing Penetration Heating |

| Conveying System | Stainless Steel & Teflon Mesh Belts |

| Feeding Mechanism | Automatic Needle-Punched Feeding |

| Reclaiming Mechanism Width | Adjustable (Compatible with Various Sizes) |

| Heating Control | PID Mode for Stable Temperature Regulation |

| Production Speed | Up to 55 Seconds per Piece (Dual-Oven Mode) |

| Material Compatibility | Non-Woven Carpets with Thermoplastic Coating |

Industry Standards and References

The Automotive Carpet Production Line adheres to rigorous industry standards for manufacturing efficiency and product quality. According to the National Institute of Standards and Technology (NIST), "Precision in manufacturing processes is critical for ensuring consistency and reliability in industrial outputs." This principle is reflected in the system’s advanced heating and control mechanisms, which align with NIST’s guidelines for high-accuracy production systems.

For further information on industry standards, refer to the NIST website.

Conclusion

The Automotive Carpet Production Line represents a significant advancement in manufacturing technology, offering unparalleled efficiency, durability, and versatility. With its state-of-the-art features and applications across multiple industries, this system is an ideal choice for manufacturers seeking to enhance productivity and product quality. By partnering with Chongqing Guang Jingxin Technology Co., Ltd., businesses can leverage cutting-edge solutions to meet the demands of modern manufacturing.

References

National Institute of Standards and Technology (NIST) (2025). "Precision Manufacturing Standards." Retrieved from https://www.nist.gov.