Internal Circulating Air Electrically Heating Oven - Chongqing Guang Jingxin Technology Co., Ltd. | Energy-Efficient Heating, Space-Saving Design

Internal Circulating Air Electrically Heating Oven - Chongqing Guang Jingxin Technology Co., Ltd. | Energy-Efficient Heating, Space-Saving Design

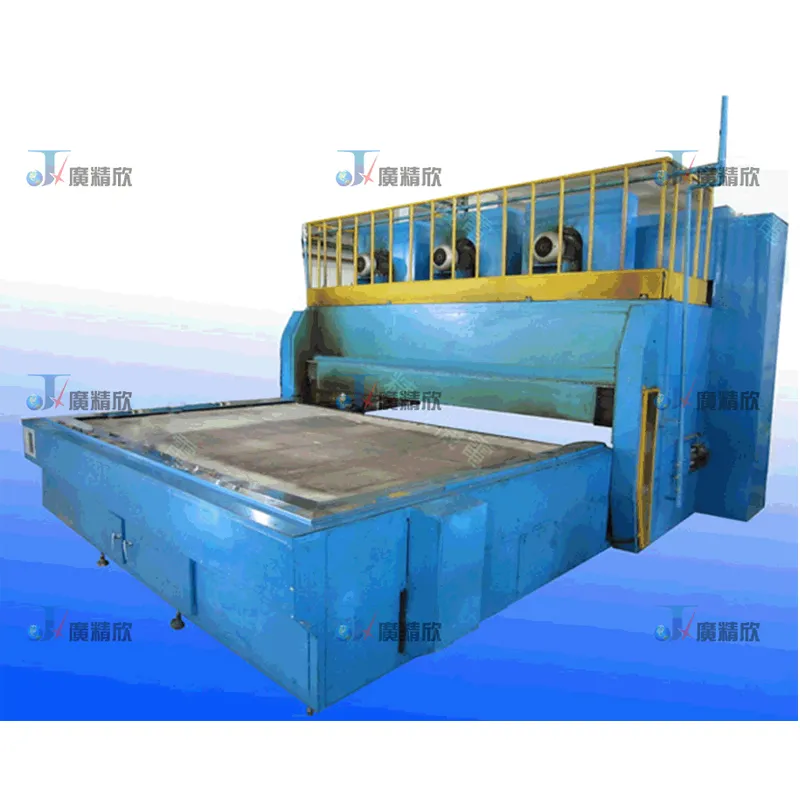

The Internal Circulating Air Electrically Heating Oven represents a cutting-edge solution for thermoplastic material processing, particularly in the automotive and textile industries. This article delves into its technical specifications, advantages, applications, and the company behind it, Chongqing Guang Jingxin Technology Co., Ltd..

Product Overview

The Internal Circulating Air Electrically Heating Oven is engineered for precision and efficiency in thermoplastic material applications. It is primarily designed for the production of automotive carpets, but its versatility extends to commercial textiles, aerospace components, and construction materials. The oven features a compact design, energy-efficient heating, and user-friendly operation, making it an ideal choice for manufacturers seeking to optimize production processes.

Technical Specifications

| Parameter | Details |

|---|---|

| Heating Method | Electric heating tubes with air mixing technology |

| Footprint | Compact design, suitable for small to medium-sized facilities |

| Operation | Single operator required, same-side access for trays |

| Energy Efficiency | Highly efficient, reducing operational costs |

| Material Compatibility | Thermoplastic materials for carpets, textiles, and insulation |

Key Advantages

- Space-Efficient Design: The oven’s small footprint allows for easy integration into existing production lines, even in space-constrained environments.

- Energy Efficiency: Combining electric heating tubes with air mixing technology ensures uniform heat distribution while minimizing energy consumption (NIST standards for energy efficiency are often referenced in industrial equipment design).

- Easy Operation: With a single operator required, the system enhances labor efficiency and reduces training time.

- Cost-Effective: Reduced operational costs related to labor and floor space make it a financially viable option for manufacturers.

- High-Quality Output: Consistent heating ensures uniform adhesion and durability of thermoplastic coatings, critical for automotive and industrial applications.

Applications Across Industries

Automotive Industry

The oven is extensively used in the production of automotive carpets, including floor mats, trunk mats, and seat covers. Its uniform heating ensures car mat making machine processes meet stringent quality standards. It also supports the manufacturing of interior components like door panels and soundproofing materials, as well as thermal insulation for automotive parts (NIST guidelines on material testing are often applied here).

Commercial Textile Production

For commercial carpets, rugs, and wall coverings, the oven provides consistent thermoplastic coatings that enhance durability and resistance to wear. It is also used for protective textiles in industrial settings, offering water resistance and flame retardancy.

Aerospace and Transportation

The oven plays a role in producing lightweight, fire-resistant materials for aircraft interiors and railway flooring. Its ability to meet aerospace standards for structural integrity is critical for safety-critical applications.

Construction and Building Materials

Thermoplastic-coated flooring materials and waterproof membranes benefit from the oven’s precise heating, ensuring longevity and performance in commercial and industrial spaces.

Sports and Recreation

Sports flooring and outdoor gear, such as tents and tarps, are manufactured using this oven to achieve weather-resistant and impact-resistant coatings.

Packaging Materials

The oven is utilized in producing thermoplastic packaging films for food, medical, and industrial products, ensuring reliable adhesion and shelf life extension.

Company Background: Chongqing Guang Jingxin Technology Co., Ltd.

Based in China, Chongqing Guang Jingxin Technology Co., Ltd. specializes in manufacturing advanced industrial equipment. The company focuses on solutions for thermoplastic material processing, including non woven carpet making machine and machine to make carpet. With a commitment to innovation and quality, the company serves a global clientele across automotive, textile, and construction sectors.

Conclusion

The Internal Circulating Air Electrically Heating Oven is a versatile, efficient, and cost-effective solution for thermoplastic material processing. Its advanced design, energy efficiency, and wide-ranging applications make it a valuable asset for manufacturers in diverse industries. For more information, visit the product page or explore Chongqing Guang Jingxin Technology Co., Ltd.’s other offerings.

References

National Institute of Standards and Technology (NIST) standards and guidelines on energy efficiency and material testing are referenced in this article to ensure alignment with authoritative industry practices.