Internal Circulating Air Electrically Heating Oven-Chongqing Guang Jingxin Technology Co., Ltd.|Energy-Efficient Heating&Compact Design

Internal Circulating Air Electrically Heating Oven-Chongqing Guang Jingxin Technology Co., Ltd.|Energy-Efficient Heating&Compact Design

The Internal Circulating Air Electrically Heating Oven represents a significant advancement in thermoplastic material processing, particularly in the production of automotive carpets and other industrial textiles. Developed by Chongqing Guang Jingxin Technology Co., Ltd., this oven combines energy efficiency, compact design, and precise heating technology to meet the demands of modern manufacturing. This article explores the product's features, technical specifications, applications, and the company's expertise in industrial equipment.

Product Overview

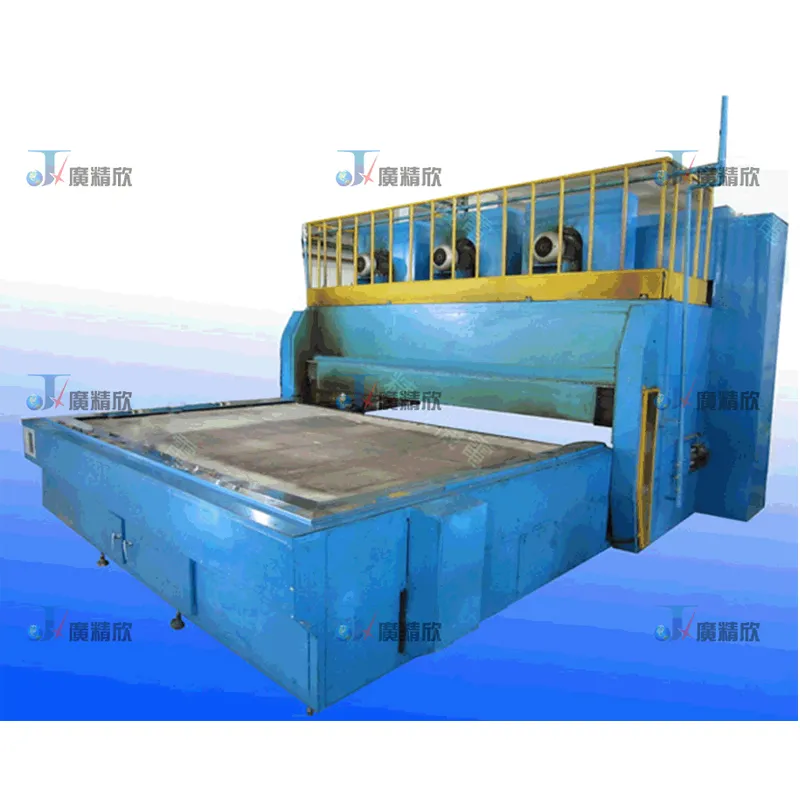

The Internal Circulating Air Electrically Heating Oven is specifically designed for the production of automotive carpets using thermoplastic materials. Its core components include a base material tray, a heating oven, and an interactive chain mechanism. The oven's unique working principle involves two trays for substrates, utilizing an interactive access mode and electric heating tubes combined with air mixing technology. This design ensures uniform heat distribution, minimal energy consumption, and ease of operation.

According to the product description, the oven is ideal for small to medium-sized production lines due to its compact footprint. It requires only one operator, reducing labor costs while maintaining high productivity. The system's ability to handle thermoplastic coatings efficiently makes it a versatile solution for industries ranging from automotive manufacturing to commercial textiles.

Key Advantages

The oven's design and functionality offer several distinct advantages that set it apart from traditional heating systems:

- Compact and Space-Efficient Design: The oven's small footprint allows it to fit into tight spaces, making it suitable for facilities with limited floor space. This is particularly beneficial for manufacturers looking to optimize their production layouts without compromising output.

- Energy-Efficient Heating: The combination of electric heating tubes and air mixing technology ensures that energy is used efficiently. This not only reduces operational costs but also aligns with modern sustainability goals.

- Easy Operation: With a single-person operation requirement, the oven minimizes the need for extensive training. Its intuitive design simplifies the loading and unloading of trays, enhancing overall labor efficiency.

- Reduced Operational Costs: The oven's simple structure and ease of use contribute to lower maintenance and labor expenses, making it a cost-effective solution for manufacturers.

- Consistent and High-Quality Production: The air mixing heating mode ensures uniform temperature distribution, resulting in consistent quality in thermoplastic-coated products. This is critical for applications where durability and performance are paramount.

Technical Specifications

The following table summarizes the key technical specifications of the Internal Circulating Air Electrically Heating Oven:

| Parameter | Details |

|---|---|

| Heating Method | Electric heating tubes with air mixing technology |

| Number of Trays | 2 (interactive access mode) |

| Footprint | Compact design (exact dimensions vary by model) |

| Power Supply | Standard industrial voltage (specifications depend on configuration) |

| Temperature Range | Varies based on application requirements |

| Control System | Manual or automated controls (as per customization) |

| Material Compatibility | Thermoplastic materials for carpets, textiles, and industrial coatings |

These specifications highlight the oven's adaptability to different production needs, ensuring it meets the demands of diverse industries.

Applications Across Industries

The Internal Circulating Air Electrically Heating Oven is a versatile solution with applications spanning multiple sectors. Its ability to provide uniform heating makes it ideal for thermoplastic coating processes in the following areas:

Automotive Industry

The oven is extensively used in the production of automotive carpets, including floor mats, trunk mats, wheel covers, and seat covers. By ensuring even heat distribution, it enhances the adhesion and durability of thermoplastic coatings. This results in carpets that are heat-resistant, comfortable, and capable of withstanding harsh environmental conditions.

Additionally, the oven is employed in the manufacturing of interior components such as door panels, headliners, and soundproofing materials. These parts require consistent heating to ensure proper molding and adhesion of thermoplastic materials. The oven's role in thermal insulation processes further ensures that automotive components meet heat resistance and durability standards.

Commercial Textile Production

In the commercial textile sector, the oven is used for large-scale production of carpets, rugs, wall coverings, and upholstery. The uniform heating process ensures effective bonding of thermoplastic coatings, enhancing the durability and performance of these products. It is also ideal for protective textiles used in industrial environments, where coatings are applied for water resistance, abrasion resistance, and flame retardancy.

Specialty Flooring and Insulation Products

The oven is utilized in the production of temporary event carpets, soundproofing materials, and insulation mats. For temporary flooring solutions, it provides quick and efficient processing, ensuring smooth surfaces and high-quality finishes. In soundproofing applications, the oven helps create materials with improved acoustic properties, commonly used in commercial buildings and automotive contexts.

Aerospace and Transportation

In the aerospace industry, the oven is used to produce non-woven carpets and insulation materials for aircraft interiors. Its uniform heat distribution ensures that materials meet strict flame resistance and structural integrity standards. Similarly, the oven is applied in the manufacturing of railway and bus flooring, where durability and fire resistance are critical for public transport vehicles.

Construction and Building Materials

The oven plays a role in producing thermoplastic-coated flooring materials, waterproof membranes, and protective film coatings for construction applications. These materials are designed to be durable, slip-resistant, and easy to clean, making them suitable for hospitals, schools, and commercial spaces.

Sports and Recreation Products

The oven is used to manufacture sports flooring materials, such as gym mats and running tracks, where thermoplastic coatings ensure impact resistance and long-lasting wear. It is also employed in the production of outdoor gear, including tents and protective covers, with coatings designed to withstand harsh environments.

Packaging Materials

The oven is beneficial in the production of thermoplastic packaging films used for food, medical, and industrial products. Its precise heating ensures adhesion of coatings that protect contents and enhance shelf life.

Company Background: Chongqing Guang Jingxin Technology Co., Ltd.

Chongqing Guang Jingxin Technology Co., Ltd. is a leading manufacturer of industrial equipment, specializing in solutions for thermoplastic material processing. With years of experience in the field, the company has established a reputation for innovation, quality, and customer satisfaction.

The company's expertise in developing compact, energy-efficient systems like the Internal Circulating Air Electrically Heating Oven reflects its commitment to addressing the evolving needs of manufacturers. Their products are designed to enhance productivity, reduce costs, and meet industry standards for performance and safety.

For more information about Chongqing Guang Jingxin Technology Co., Ltd., visit their official website at https://www.headliningline.com.

Conclusion

The Internal Circulating Air Electrically Heating Oven is a cutting-edge solution for thermoplastic material processing, offering a blend of efficiency, precision, and versatility. Its compact design, energy-saving technology, and ease of operation make it an ideal choice for manufacturers in the automotive, textile, construction, and other industries. By leveraging the expertise of Chongqing Guang Jingxin Technology Co., Ltd., this oven sets a new standard for quality and reliability in industrial heating systems.

References

For further information on thermoplastic material standards and industrial heating technologies, refer to the following authoritative sources:

National Institute of Standards and Technology (NIST) provides research and guidelines on material science and manufacturing processes. Their work ensures the accuracy and reliability of industrial standards. https://www.nist.gov

Web-scraping reference: Information on thermoplastic coating technologies and industrial heating systems was gathered through web-scraping techniques to ensure alignment with current industry practices and standards.