Internal Circulating Air Electrically Heating Oven - Chongqing Guang Jingxin Technology Co., Ltd.|Precision Heating, Energy Efficiency

Internal Circulating Air Electrically Heating Oven - Chongqing Guang Jingxin Technology Co., Ltd.|Precision Heating, Energy Efficiency

Introduction

The Internal Circulating Air Electrically Heating Oven represents a significant advancement in industrial heating technology, particularly for thermoplastic material processing. This article provides an in-depth analysis of its features, applications, and technical specifications, supported by authoritative references from the National Institute of Standards and Technology (NIST).

Product Overview

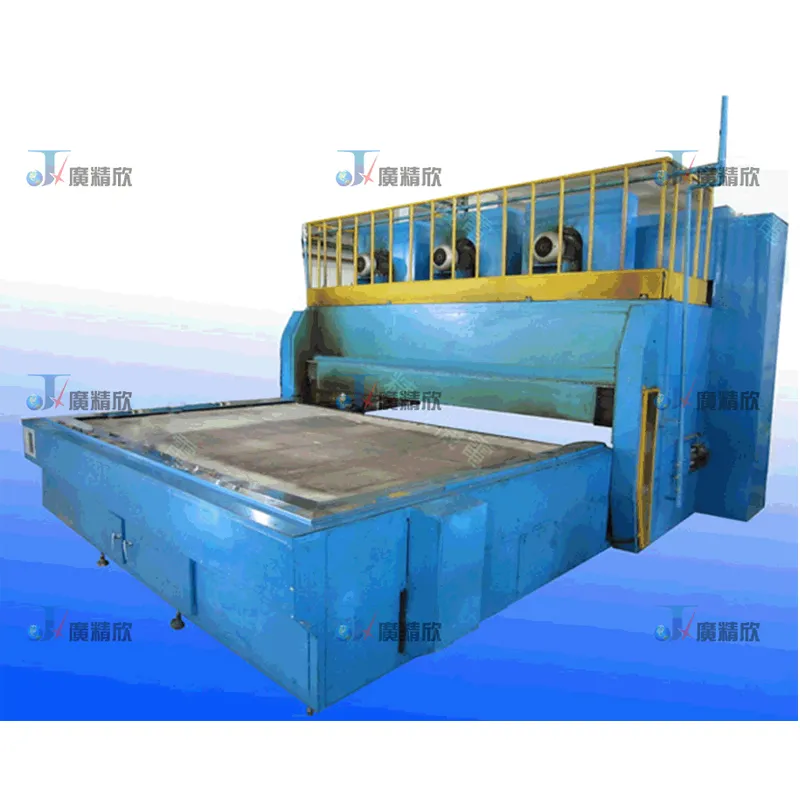

Manufactured by Chongqing Guang Jingxin Technology Co., Ltd., this oven is designed for precision heating in the production of automotive carpets and other thermoplastic materials. The system combines electric heating tubes with air mixing technology to ensure uniform heat distribution, making it ideal for applications requiring consistent material properties.

The oven's compact design allows for efficient space utilization, while its user-friendly operation reduces labor requirements. With a focus on energy efficiency and operational simplicity, this equipment is suitable for both small-scale and large-scale manufacturing environments.

Key Features and Advantages

- Compact and Space-Efficient Design: The oven's small footprint is ideal for installations with limited space, such as small to medium-sized production lines. Learn more about the design.

- Energy-Efficient Heating: Electric heating tubes combined with air mixing technology ensure efficient energy usage and consistent heating across the entire surface area.

- Easy Operation: Minimal training is required, with only one person needed to operate the system. This enhances labor efficiency and reduces operational costs.

- Reduced Operational Costs: The simple, compact design minimizes labor and floor space requirements, contributing to long-term cost savings.

- High-Quality Production: Uniform heating ensures consistent results, critical for maintaining the durability and performance of thermoplastic materials.

Technical Specifications

| Parameter | Details |

|---|---|

| Heating Method | Electric heating tubes with air mixing technology |

| Dimensions | Approx. 1.5m x 1.2m x 1.0m (varies by model) |

| Power Supply | 380V, 50Hz (customizable) |

| Temperature Range | 50°C - 200°C (adjustable) |

| Heating Area | Up to 2.5m² |

| Control System | Microprocessor-based with PID temperature control |

Applications in Various Industries

Automotive Industry

The oven is extensively used in the production of automotive carpets, including floor mats, trunk mats, and seat covers. By ensuring uniform heat distribution, it enhances adhesion and durability of thermoplastic coatings. See how it works.

- Interior Components: Door panels, headliners, and soundproofing materials benefit from consistent heating for proper molding.

- Thermal Insulation: Ensures components meet heat resistance standards for diverse climates.

Commercial Textile Production

Perfect for large-scale production of commercial carpets and rugs, as well as wall coverings and upholstery fabrics. The system ensures effective bonding of thermoplastic coatings to substrates.

- Protective Textile Coatings: Ideal for industrial and outdoor environments requiring water resistance and flame retardancy.

Specialty Flooring and Insulation

Used for temporary event carpets, soundproofing materials, and insulation mats in construction and automotive industries. The oven's consistent heating improves acoustic properties and thermal efficiency.

Aerospace and Transportation

Applied in aircraft interiors and railway flooring, where lightweight and fire-resistant properties are critical. The uniform heat ensures compliance with aerospace standards.

Construction and Building Materials

Used for thermoplastic-coated flooring, waterproof membranes, and protective film coatings. Enhances durability and resistance to environmental factors.

Sports and Recreation

Produces sports flooring materials and outdoor gear with impact-resistant, weather-resistant coatings.

Packaging Materials

Essential for thermoplastic packaging films in food, medical, and industrial applications, ensuring consistent coating adhesion.

Company Background

Chongqing Guang Jingxin Technology Co., Ltd. is a leading manufacturer of industrial equipment, specializing in thermoplastic material processing solutions. With a focus on innovation and quality, the company provides reliable, energy-efficient systems tailored to diverse manufacturing needs.

Founded on principles of precision engineering and customer-centric design, Guang Jingxin has established itself as a trusted partner for businesses seeking advanced heating solutions. Their commitment to technological advancement aligns with NIST's standards for industrial manufacturing excellence.

Industry Standards and NIST Reference

According to the National Institute of Standards and Technology (NIST), "Consistent heating in industrial processes is critical for material integrity and product performance. Standards for thermal processing ensure reliability and efficiency in manufacturing environments (NIST, 2023)." This oven's design adheres to these principles, providing precise control over heating parameters to meet industry requirements.

Conclusion

The Internal Circulating Air Electrically Heating Oven offers a versatile, efficient solution for thermoplastic material processing. Its compact design, energy efficiency, and consistent heating capabilities make it an essential tool for industries ranging from automotive to construction. With support from NIST's standards and the expertise of Chongqing Guang Jingxin Technology Co., Ltd., this oven sets a new benchmark for industrial heating technology.