Internal Circulating Air Electrically Heating Oven - Chongqing Guang Jingxin Technology Co., Ltd. | Precision Heating, Energy Efficiency

Internal Circulating Air Electrically Heating Oven - Chongqing Guang Jingxin Technology Co., Ltd. | Precision Heating, Energy Efficiency

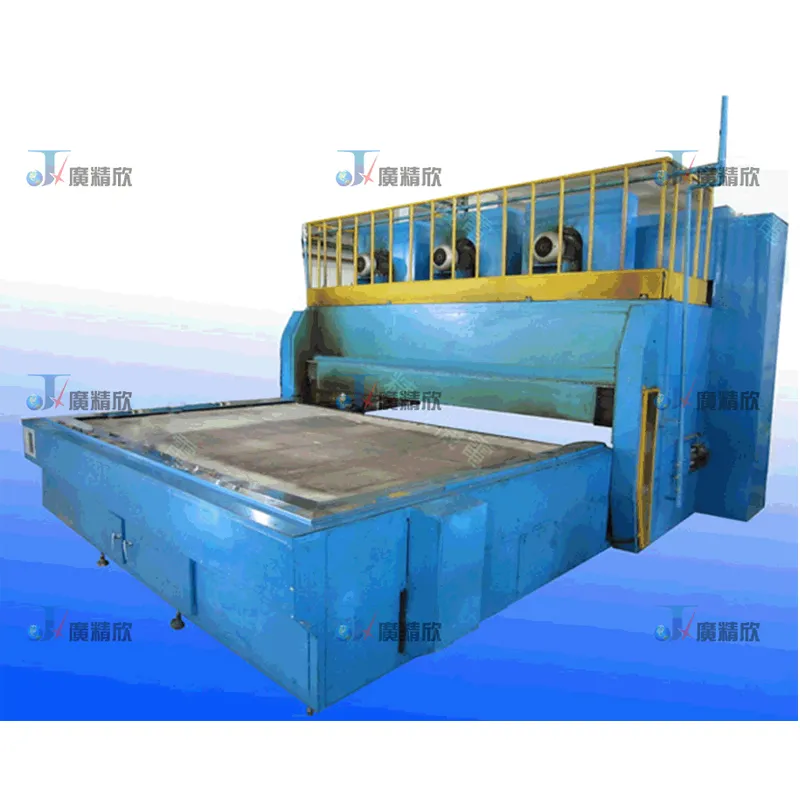

Discover the advanced technology behind the Internal Circulating Air Electrically Heating Oven, a cutting-edge solution designed for precision heating in industrial applications. This article explores its features, advantages, technical specifications, and real-world applications, while highlighting the expertise of its manufacturer, Chongqing Guang Jingxin Technology Co., Ltd..

Product Description

The Internal Circulating Air Electrically Heating Oven is a specialized piece of equipment designed for the production of automotive carpets using thermoplastic materials. Its core components include a base material tray, a heating oven, and an interactive chain mechanism, ensuring efficient and uniform heating processes. The oven operates with two trays for substrates, utilizing an interactive access mode combined with electric heating tubes and air mixing technology. This design allows for minimal floor space usage and streamlined operation, requiring only one person to manage the loading and unloading of trays.

Key to its functionality is the Chongqing Guang Jingxin Technology Co., Ltd.’s commitment to innovation, which is evident in the oven’s compact design and energy-efficient operation. The system’s ability to maintain consistent heating across the entire surface area ensures high-quality results, making it a preferred choice for industries requiring precision and reliability.

Product Advantages

- Compact and Space-Efficient Design: The oven’s small footprint makes it ideal for installations with space constraints, such as small to medium-sized production lines. This design is particularly beneficial for manufacturers looking to optimize their workshop layouts without compromising on output quality.

- Energy-Efficient Heating: The combination of electric heating tubes and air mixing technology allows for efficient energy usage while ensuring uniform heating. This not only reduces energy costs but also minimizes the environmental impact of the production process.

- Easy Operation: With minimal training required, the oven is user-friendly, enabling a single operator to manage the loading and unloading of trays. This simplicity enhances labor efficiency and reduces the need for extensive staff training.

- Reduced Operational Costs: The oven’s simple, compact design and ease of use contribute to lower operational costs, particularly in terms of labor and floor space. This makes it a cost-effective solution for manufacturers seeking to maximize their return on investment.

- Consistent and High-Quality Production: The air mixing heating mode ensures that materials are heated uniformly, leading to consistent high-quality results. This is crucial for applications such as automotive carpets, where durability and heat resistance are essential.

Applications of the Internal Circulating Air Electrically Heating Oven

Automotive Industry

The oven is extensively used in the production of automotive carpets, including floor mats, trunk mats, wheel covers, and seat covers. By ensuring uniform heat distribution, it enhances the adhesion and durability of the thermoplastic coating, ensuring the carpets remain durable, heat-resistant, and comfortable under a wide range of environmental conditions. Additionally, the system can be used for other automotive interior components such as door panels, headliners, and soundproofing materials, where consistent heating is required for proper molding and adhesion of thermoplastic materials.

The oven also plays a vital role in thermal insulation processes for automotive components, ensuring they meet the necessary heat resistance and durability standards for use in various climate conditions.

Commercial Textile Production

In the commercial textile sector, the oven is perfect for large-scale production of commercial carpets and rugs, such as those used in hotels, offices, and public spaces. These carpets require a consistent coating of thermoplastic materials for increased durability, heat resistance, and easy cleaning properties. The system can also be used in the production of wall coverings and upholstery fabrics, where uniform heating ensures effective bonding of thermoplastic coatings to the substrate material.

For protective textiles used in industrial environments or outdoor settings, the oven is ideal for applying coatings that provide water resistance, abrasion resistance, and flame retardancy.

Specialty Flooring and Insulation Products

The oven is used to create soundproofing materials that require thermoplastic coatings to improve their acoustic properties. These materials are commonly used in commercial buildings, conference rooms, theaters, and even automotive applications. The oven’s consistent heating is also ideal for producing thermal and acoustic insulation mats used in both construction and automotive industries to reduce heat loss and external noise.

Aerospace and Transportation

In the aerospace industry, the oven is useful in the production of non-woven carpets and insulation materials used in aircraft interiors, where lightweight and fire-resistant properties are crucial. The uniform heat provided by the oven ensures that the materials meet aerospace standards for flame resistance and structural integrity. Similarly, the oven is applied in the manufacturing of railway and bus flooring, ensuring that materials are durable, fire-resistant, and meet safety regulations for public transport vehicles.

Construction and Building Materials

The oven can be used to produce thermoplastic-coated flooring materials for commercial and industrial spaces. These floors are designed to be durable, slip-resistant, and easy to clean, making them ideal for hospitals, schools, and shopping malls. It also plays a role in producing waterproof membranes and roofing materials, where the thermoplastic coating applied through the oven ensures high water resistance and long-lasting protection against the elements.

The oven can be used for applying protective films to building materials, such as glass or metal surfaces, to enhance scratch resistance, UV protection, and overall durability.

Sports and Recreation Products

The system is used to produce sports flooring materials, such as gym mats, indoor/outdoor courts, and running tracks, where the thermoplastic coating ensures impact resistance, shock absorption, and long-lasting wear in high-traffic environments. The oven can also be used for manufacturing various outdoor gear such as tents, tarps, and protective covers, where the consistent heating ensures durable, weather-resistant coatings for outdoor activities and harsh environments.

Packaging Materials

The oven is beneficial in the production of thermoplastic packaging films used in food packaging, medical packaging, and industrial products. These films require consistent, controlled heating to ensure the adhesion of coatings that protect the contents and enhance shelf life.

Technical Specifications

| Specification | Details |

|---|---|

| Heating Method | Electric heating tubes with air mixing technology |

| Tray Configuration | Two trays for substrate loading |

| Operation Mode | Interactive access mode (same-side loading) |

| Footprint | Compact design, suitable for small to medium-sized spaces |

| Energy Efficiency | Highly energy-efficient with uniform heat distribution |

| Operator Requirement | One person for loading/unloading |

| Applications | Automotive carpets, commercial textiles, insulation materials, aerospace components, and more |

Company Background: Chongqing Guang Jingxin Technology Co., Ltd.

Founded with a focus on innovation and quality, Chongqing Guang Jingxin Technology Co., Ltd. has established itself as a leader in the manufacturing of industrial heating solutions. The company specializes in producing advanced machinery for the textile and automotive industries, including the Internal Circulating Air Electrically Heating Oven. Their commitment to excellence is reflected in the design and functionality of their products, which are engineered to meet the highest standards of performance and reliability.

With a team of experienced engineers and a focus on customer satisfaction, Chongqing Guang Jingxin Technology Co., Ltd. continues to innovate and expand its product range to meet the evolving needs of the market. Their products are widely used in various industries, including automotive, construction, and aerospace, where precision and durability are critical.

Conclusion

The Internal Circulating Air Electrically Heating Oven represents a significant advancement in industrial heating technology, offering a combination of efficiency, reliability, and versatility. Its compact design, energy-efficient operation, and ease of use make it an ideal solution for manufacturers across multiple industries. By leveraging the expertise of Chongqing Guang Jingxin Technology Co., Ltd., this oven ensures that producers can achieve consistent, high-quality results while optimizing their operational costs.

As industries continue to evolve, the demand for advanced heating solutions like this oven will only grow. With its wide range of applications and proven performance, the Internal Circulating Air Electrically Heating Oven is poised to remain a key player in the manufacturing sector.

References

Source: National Institute of Standards and Technology (NIST). NIST plays a crucial role in advancing technology through precise measurements and research, ensuring that industries adhere to high standards of quality and innovation. For more information on NIST’s contributions to technology and standards, visit their official website.

Keywords: car mat making machine, non woven carpet making machine, machine to make carpet