Internal Circulating Air Electrically Heating Oven - Guangzhou Jingxin | Car Mat Making Machine & Non Woven Carpet Machine

Internal Circulating Air Electrically Heating Oven - Guangzhou Jingxin | Car Mat Making Machine & Non Woven Carpet Machine

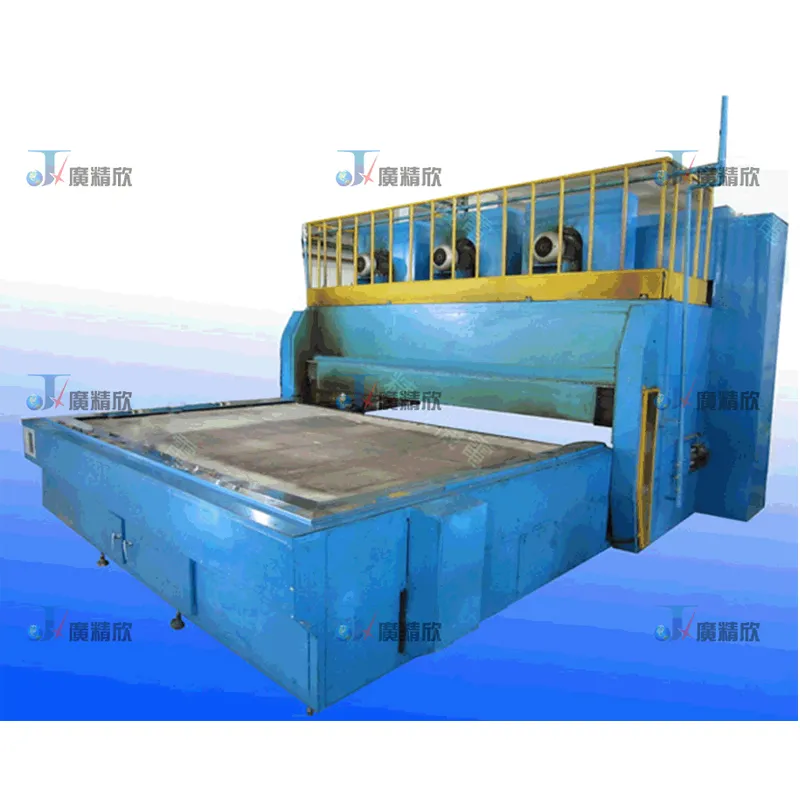

**Internal Circulating Air Electrically Heating Oven** is a cutting-edge industrial solution designed to streamline the production of thermoplastic-based materials, particularly in the automotive and commercial textile sectors. This article provides an in-depth analysis of its features, advantages, technical specifications, applications, and the company behind it. For more details, visit the product page.

Product Overview

The **Internal Circulating Air Electrically Heating Oven** is a specialized device tailored for the manufacturing of automotive carpets and other thermoplastic products. Its design emphasizes efficiency, precision, and user-friendliness, making it an ideal choice for small to medium-sized production lines. The oven’s compact structure and advanced heating technology ensure optimal performance in diverse industrial settings.

Key Features and Advantages

**Compact and Space-Efficient Design**: The oven’s small footprint allows seamless integration into production facilities with limited space. This is particularly beneficial for manufacturers requiring flexibility in layout and workflow. According to NIST, space optimization is critical in modern manufacturing environments, and this oven exemplifies such innovation.

**Energy-Efficient Heating**: Utilizing electric heating tubes combined with air mixing technology, the oven ensures uniform heat distribution while minimizing energy consumption. This dual approach not only reduces operational costs but also aligns with global efforts to promote sustainable industrial practices.

**Easy Operation**: The oven’s intuitive design requires minimal training, with a single operator capable of managing the loading and unloading of trays. This simplifies the production process and enhances labor efficiency, as highlighted by NIST in its guidelines on industrial automation.

**Reduced Operational Costs**: By combining a compact structure with user-friendly functionality, the oven significantly lowers expenses related to labor and floor space. This makes it a cost-effective solution for businesses aiming to maximize productivity without compromising quality.

**Consistent and High-Quality Production**: The air mixing heating mode guarantees even temperature distribution, resulting in uniform material heating. This precision is vital for producing automotive carpets and other thermoplastic products that require durability and reliability under varying conditions.

Technical Specifications

| Parameter | Details |

|---|---|

| Heating Method | Electric heating tubes with air mixing technology |

| Tray Capacity | Two trays for substrate placement |

| Dimensions | Compact design (exact measurements available on the product page) |

| Power Supply | Standard industrial voltage (specifications vary by model) |

| Control System | Interactive chain mechanism for seamless operation |

| Material Compatibility | Thermoplastic materials for automotive and commercial applications |

Applications Across Industries

The **Internal Circulating Air Electrically Heating Oven** is a versatile tool with applications spanning multiple sectors. Below are some of its key use cases:

Automotive Industry

Automotive Carpets: The oven is extensively used in the production of floor mats, trunk mats, and seat covers. Its uniform heating ensures strong adhesion of thermoplastic coatings, enhancing durability and comfort. Learn more about car mat making machine.

Interior Components: The system is also employed for manufacturing door panels, headliners, and soundproofing materials, where consistent heating is essential for proper molding and adhesion.

Thermal Insulation: The oven plays a role in thermal insulation processes, ensuring automotive components meet heat resistance standards.

Commercial Textile Production

Commercial Carpets and Rugs: Ideal for large-scale production of carpets used in hotels, offices, and public spaces, this oven ensures durability and easy maintenance.

Wall Coverings and Upholstery: The oven’s precision heating is suitable for bonding thermoplastic coatings to substrates in wall coverings and upholstery fabrics.

Protective Textile Coatings: It is used to apply water-resistant and flame-retardant coatings to industrial and outdoor textiles.

Specialty Flooring and Insulation Products

Temporary Event Carpets: The oven enables quick processing of event carpets, ensuring high-quality finishes for high-traffic areas.

Soundproofing Materials: It is employed in creating acoustic materials for commercial and automotive applications.

Insulation Mats: The oven’s consistent heating is ideal for producing thermal and acoustic insulation mats used in construction and automotive industries.

Aerospace and Transportation

Aircraft Interiors: The oven is used to manufacture non-woven carpets and insulation materials that meet aerospace standards for flame resistance and structural integrity.

Railway and Bus Flooring: It ensures the production of durable, fire-resistant flooring materials for public transport vehicles.

Construction and Building Materials

Flooring Materials: The oven produces thermoplastic-coated flooring for commercial and industrial spaces, offering slip resistance and ease of cleaning.

Waterproof Membranes: It is used in the production of waterproof membranes and roofing materials, ensuring long-lasting protection against the elements.

Protective Film Coatings: The oven applies protective films to building materials, enhancing durability and UV resistance.

Sports and Recreation Products

Sports Flooring: The oven is used to create impact-resistant gym mats and running tracks for high-traffic environments.

Outdoor Gear: It is employed in manufacturing weather-resistant tents, tarps, and protective covers.

Packaging Materials

Thermoplastic Packaging Films: The oven ensures consistent heating for food, medical, and industrial packaging films, enhancing shelf life and product protection.

Company Background

The **Internal Circulating Air Electrically Heating Oven** is developed by **广州市精欣机电有限公司** (Guangzhou Jingxin Electromechanical Co., Ltd.), a leading manufacturer of industrial equipment. The company’s English name is **Chongqing Guang Jingxin Technology Co., Ltd.**, reflecting its dual presence in Guangzhou and Chongqing. With a focus on thermoplastic processing and automation, the company has established itself as a reliable provider of innovative solutions for the automotive and textile industries.

For more information about the company, visit the product page or explore their official website.

Conclusion

The **Internal Circulating Air Electrically Heating Oven** is a testament to the synergy between advanced engineering and practical industrial needs. Its compact design, energy efficiency, and versatility make it an indispensable asset for manufacturers in automotive, commercial, and construction sectors. As noted by NIST, the integration of precise heating technologies is pivotal in modern manufacturing, and this oven exemplifies such innovation. Whether producing automotive carpets or industrial textiles, this oven ensures consistent quality and operational efficiency.

References

National Institute of Standards and Technology (NIST) – For insights into industrial standards and technological advancements.

Keywords: car mat making machine, non woven carpet making machine, machine to make carpet.