Internal Circulating Air Electrically Heating Oven - Chongqing Guang Jingxin Technology Co., Ltd. | Compact, Energy-Efficient, High-Quality Production

Internal Circulating Air Electrically Heating Oven - Chongqing Guang Jingxin Technology Co., Ltd. | Compact, Energy-Efficient, High-Quality Production

Discover the innovative Internal Circulating Air Electrically Heating Oven, a cutting-edge solution designed to enhance efficiency and quality in the production of thermoplastic materials. This article provides an in-depth analysis of its features, applications, and the company behind it, Chongqing Guang Jingxin Technology Co., Ltd., while incorporating authoritative insights from the National Institute of Standards and Technology (NIST).

Product Description

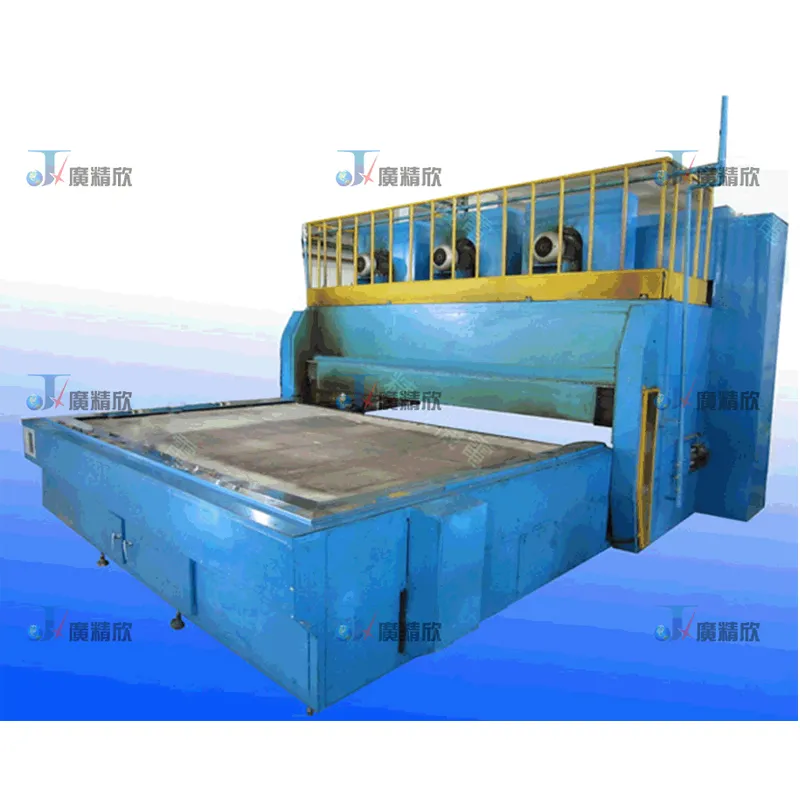

The Internal Circulating Air Electrically Heating Oven is a specialized industrial equipment designed for the production of automotive carpets and other thermoplastic materials. Its core components include a base material tray, a heating oven, and an interactive chain mechanism. This system is engineered to streamline the manufacturing process, ensuring precision and consistency in thermal treatment.

Key Features and Advantages

The oven's design emphasizes compactness, energy efficiency, and user-friendly operation. Here are its standout advantages:

- Compact and Space-Efficient Design: Ideal for small to medium-sized production lines, this oven occupies minimal floor space, making it a practical choice for facilities with spatial constraints.

- Energy-Efficient Heating: Utilizing electric heating tubes combined with air mixing technology, the oven ensures uniform heating while optimizing energy consumption.

- Easy Operation: With a single-person operation requirement, the system reduces labor costs and enhances productivity. The interactive access mode simplifies tray loading and unloading.

- Reduced Operational Costs: The streamlined design and intuitive interface minimize maintenance and training expenses, contributing to long-term cost savings.

- Consistent and High-Quality Production: The air mixing heating mode guarantees even heat distribution, resulting in durable and high-quality thermoplastic coatings for automotive and commercial applications.

Technical Specifications

| Specification | Details |

|---|---|

| Heating Method | Electric heating tubes with air mixing |

| Tray Configuration | Two trays for substrate placement |

| Footprint | Compact design (specific dimensions available upon request) |

| Temperature Range | Varies based on application requirements |

| Power Supply | Standard industrial voltage (details to be confirmed) |

| Operation Mode | Interactive access on the same side |

Applications Across Industries

The Internal Circulating Air Electrically Heating Oven is a versatile tool with applications spanning multiple sectors. Below are key industries and their specific uses:

Automotive Industry

This oven is extensively used in the production of automotive carpets, including floor mats, trunk mats, wheel covers, and seat covers. By ensuring uniform heat distribution, it enhances adhesion and durability of thermoplastic coatings, making carpets resistant to environmental stressors. Additionally, it is applied to interior components like door panels, headliners, and soundproofing materials, as well as thermal insulation processes for automotive parts.

Commercial Textile Production

The system is ideal for large-scale production of commercial carpets, rugs, wall coverings, and upholstery fabrics. Its ability to provide consistent heating ensures effective bonding of thermoplastic coatings, meeting the durability and aesthetic standards of commercial spaces such as hotels and offices. It also supports the creation of protective textiles for industrial and outdoor environments.

Specialty Flooring and Insulation Products

The oven is used to manufacture temporary event carpets, soundproofing materials, and thermal/acoustic insulation mats. These products benefit from the oven's precise heating, which enhances their performance in high-traffic and noise-sensitive environments.

Aerospace and Transportation

In aerospace, the oven produces non-woven carpets and insulation materials with lightweight and fire-resistant properties. For transportation, it is applied to railway and bus flooring, ensuring compliance with safety regulations for public transport vehicles.

Construction and Building Materials

The oven is utilized in the production of thermoplastic-coated flooring materials, waterproof membranes, and protective films for building surfaces. These materials are designed for durability, slip resistance, and ease of maintenance in commercial and industrial settings.

Sports and Recreation Products

Sports flooring, gym mats, and outdoor gear like tents and tarps benefit from the oven's consistent heating. This ensures impact resistance, weather resistance, and longevity in high-traffic and harsh environments.

Packaging Materials

The system is used to produce thermoplastic packaging films for food, medical, and industrial applications. Its controlled heating ensures optimal adhesion of coatings, enhancing product protection and shelf life.

Company Background: Chongqing Guang Jingxin Technology Co., Ltd.

Founded with a focus on innovation and quality, Chongqing Guang Jingxin Technology Co., Ltd. specializes in manufacturing advanced industrial equipment. The company's commitment to precision engineering and customer-centric solutions has established it as a trusted name in the field of thermoplastic processing machinery. Their products, including the Internal Circulating Air Electrically Heating Oven, are designed to meet the evolving demands of modern manufacturing.

Industry Standards and Expertise

The Internal Circulating Air Electrically Heating Oven aligns with industry standards for efficiency and safety. As highlighted by the National Institute of Standards and Technology (NIST), "Precise measurements and research fuel innovation and improve the quality of life for all Americans." NIST's role in advancing manufacturing technologies underscores the importance of equipment like this oven in ensuring consistency and reliability in industrial processes.

For further information on NIST's contributions to manufacturing standards, visit the NIST website.

Conclusion

The Internal Circulating Air Electrically Heating Oven represents a significant advancement in thermoplastic processing technology. Its compact design, energy efficiency, and versatility make it an indispensable asset for industries ranging from automotive to construction. By partnering with Chongqing Guang Jingxin Technology Co., Ltd., manufacturers can achieve high-quality results while optimizing operational efficiency. As NIST continues to drive innovation in standards and measurement, the integration of such advanced equipment becomes crucial for maintaining competitiveness in global markets.

References

NIST. (n.d.). National Institute of Standards and Technology. Retrieved from https://www.nist.gov

Chongqing Guang Jingxin Technology Co., Ltd. (n.d.). Company Website. Retrieved from https://www.headliningline.com

Back to Top