Internal Circulating Air Electric Heating Oven - Guangzhou Jingxin | Compact, Energy-Efficient, Easy Operation

Internal Circulating Air Electric Heating Oven - Guangzhou Jingxin | Compact, Energy-Efficient, Easy Operation

Product Overview

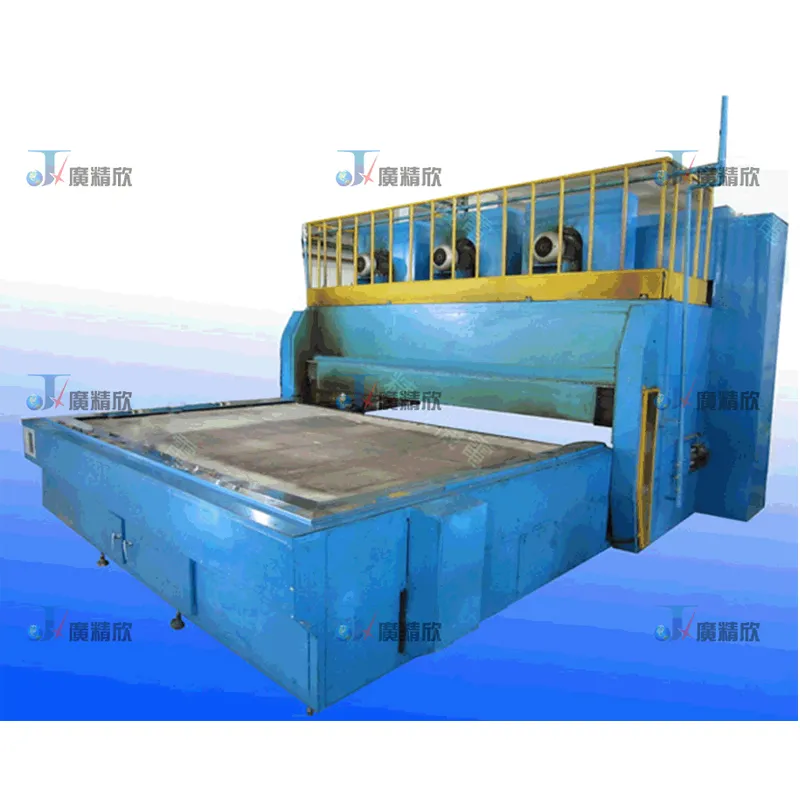

The Internal Circulating Air Electrically Heating Oven is a cutting-edge industrial solution designed for the efficient processing of thermoplastic materials. This oven is particularly renowned for its application in the production of automotive carpets, where it ensures uniform heat distribution and enhances material adhesion. The oven's compact design, energy efficiency, and user-friendly operation make it a preferred choice for manufacturers seeking to optimize their production processes.

Key Features and Advantages

The Internal Circulating Air Electrically Heating Oven stands out due to its innovative design and advanced technological features. Here are the primary advantages:

- Compact and Space-Efficient Design: The oven's small footprint is ideal for installations with limited space, making it suitable for small to medium-sized production lines. This design not only saves floor space but also reduces the need for additional infrastructure, lowering overall operational costs.

- Energy-Efficient Heating: Utilizing electric heating tubes combined with air mixing technology, the oven ensures efficient energy usage while maintaining consistent heating across the entire surface area. This feature is critical for achieving uniform material processing, which is essential in applications requiring precise thermal control.

- Easy Operation: The oven is designed for simplicity, requiring minimal training for operation. With a single operator managing the loading and unloading of trays, the system significantly enhances labor efficiency, reducing the need for multiple workers and streamlining the production workflow.

- Reduced Operational Costs: The oven's straightforward design and ease of use contribute to lower operational costs. By minimizing labor requirements and optimizing energy consumption, manufacturers can achieve substantial savings, particularly in high-volume production environments.

- Consistent and High-Quality Production: The air mixing heating mode ensures uniform heat distribution, which is crucial for producing high-quality automotive carpets. This consistency not only improves the durability and heat resistance of the final products but also enhances their comfort and aesthetic appeal.

Technical Specifications

| Feature | Description |

|---|---|

| Heating Mechanism | Electric heating tubes with air mixing technology for uniform heat distribution. |

| Tray Configuration | Two trays for substrate placement, utilizing an interactive access mode. |

| Space Efficiency | Compact design suitable for small to medium-sized production lines. |

| Operational Requirements | Single operator required for loading and unloading, with minimal training needed. |

| Energy Efficiency | Optimized energy consumption through advanced heating and air circulation systems. |

| Material Compatibility | Designed for thermoplastic materials used in automotive and industrial applications. |

Applications Across Industries

The Internal Circulating Air Electrically Heating Oven is a versatile solution with applications spanning multiple industries. Below are some key areas where this oven is extensively utilized:

Automotive Industry

- Automotive Carpets: The oven is used in the production of floor mats, trunk mats, wheel covers, and seat covers. Its uniform heating ensures that thermoplastic coatings adhere effectively, enhancing the durability and heat resistance of the carpets.

- Interior Components: The system is also employed for manufacturing automotive interior components such as door panels, headliners, and soundproofing materials. These parts require consistent heating to ensure proper molding and adhesion of thermoplastic materials.

- Thermal Insulation: The oven plays a role in thermal insulation processes for automotive components, ensuring they meet heat resistance and durability standards for various climate conditions.

Commercial Textile Production

- Commercial Carpets and Rugs: The oven is ideal for large-scale production of commercial carpets and rugs, such as those used in hotels, offices, and public spaces. These carpets require a consistent coating of thermoplastic materials for increased durability and easy cleaning.

- Wall Coverings and Upholstery: The system is used in the production of wall coverings and upholstery fabrics, where uniform heating ensures effective bonding of thermoplastic coatings to the substrate material.

- Protective Textile Coatings: The oven is suitable for protective textiles used in industrial environments or outdoor settings, where coatings are applied for water resistance, abrasion resistance, and flame retardancy.

Specialty Flooring and Insulation Products

- Temporary Event Carpets: For temporary flooring solutions such as event carpets used in exhibitions, trade shows, and conferences, the oven provides quick and efficient processing, ensuring smooth surfaces and high-quality finishes.

- Soundproofing Materials: The oven is used to create soundproofing materials that require thermoplastic coatings to improve their acoustic properties. These materials are commonly used in commercial buildings, conference rooms, theaters, and automotive applications.

- Insulation Mats: The oven's consistent heating is ideal for producing thermal and acoustic insulation mats used in both construction and automotive industries to reduce heat loss and external noise.

Aerospace and Transportation

- Aircraft Interiors: The oven is useful in the production of non-woven carpets and insulation materials used in aircraft interiors, where lightweight and fire-resistant properties are crucial. The uniform heat provided by the oven ensures that the materials meet aerospace standards for flame resistance and structural integrity.

- Railway and Bus Flooring: Similarly, the oven is applied in the manufacturing of railway and bus flooring, ensuring that materials are durable, fire-resistant, and meet safety regulations for public transport vehicles.

Construction and Building Materials

- Flooring Materials for Commercial Buildings: The oven can be used to produce thermoplastic-coated flooring materials for commercial and industrial spaces. These floors are designed to be durable, slip-resistant, and easy to clean, making them ideal for hospitals, schools, and shopping malls.

- Waterproof Membranes and Roofing Materials: It also plays a role in producing waterproof membranes and roofing materials. The thermoplastic coating applied through the oven ensures that the materials have high water resistance and long-lasting protection against the elements.

- Protective Film Coatings: The oven can be used for applying protective films to building materials, such as glass or metal surfaces, to enhance scratch resistance, UV protection, and overall durability.

Sports and Recreation Products

- Sports Flooring: The system is used to produce sports flooring materials, such as gym mats, indoor/outdoor courts, and running tracks, where the thermoplastic coating ensures impact resistance, shock absorption, and long-lasting wear in high-traffic environments.

- Outdoor Gear and Equipment: The oven can be used for manufacturing various outdoor gear such as tents, tarps, and protective covers. The consistent heating ensures durable, weather-resistant coatings for outdoor activities and harsh environments.

Packaging Materials

- Thermoplastic Packaging Films: The oven is beneficial in the production of thermoplastic packaging films used in food packaging, medical packaging, and industrial products. These films require consistent, controlled heating to ensure the adhesion of coatings that protect the contents and enhance shelf life.

Company Background: Guangzhou Jingxin Electromechanical Co., Ltd.

The Internal Circulating Air Electrically Heating Oven is developed by Guangzhou Jingxin Electromechanical Co., Ltd., a leading manufacturer specializing in industrial machinery and equipment. The company is known for its commitment to innovation, quality, and customer satisfaction, providing reliable solutions for diverse manufacturing needs.

With a focus on advanced engineering and precision manufacturing, Guangzhou Jingxin Electromechanical Co., Ltd. has established itself as a trusted partner for businesses seeking efficient and durable production equipment. Their products, including the Internal Circulating Air Electrically Heating Oven, are designed to meet the stringent requirements of modern manufacturing environments, ensuring optimal performance and long-term value.

Conclusion: Enhancing Manufacturing Efficiency with the Internal Circulating Air Electrically Heating Oven

The Internal Circulating Air Electrically Heating Oven represents a significant advancement in industrial heating technology. Its compact design, energy efficiency, and user-friendly operation make it an indispensable tool for manufacturers in the automotive, textile, aerospace, and construction industries. By ensuring uniform heat distribution and consistent product quality, this oven not only enhances production efficiency but also contributes to cost savings and environmental sustainability.

As industries continue to evolve, the demand for reliable and efficient manufacturing solutions will only grow. Guangzhou Jingxin Electromechanical Co., Ltd. remains at the forefront of this innovation, delivering cutting-edge products that meet the needs of modern production environments. For businesses seeking to optimize their operations and achieve high-quality results, the Internal Circulating Air Electrically Heating Oven is a compelling choice that combines advanced technology with practical functionality.

References

1. NIST (National Institute of Standards and Technology). https://www.nist.gov/. NIST plays a crucial role in advancing technology through its research and development in measurement science, standards, and innovation. The principles of precision and efficiency emphasized by NIST align with the design and functionality of the Internal Circulating Air Electrically Heating Oven, ensuring that industrial processes meet the highest standards of quality and reliability.