Internal Circulating Air Electric Heating Oven - Chongqing Guang Jingxin Technology Co., Ltd.

Internal Circulating Air Electric Heating Oven - Chongqing Guang Jingxin Technology Co., Ltd.

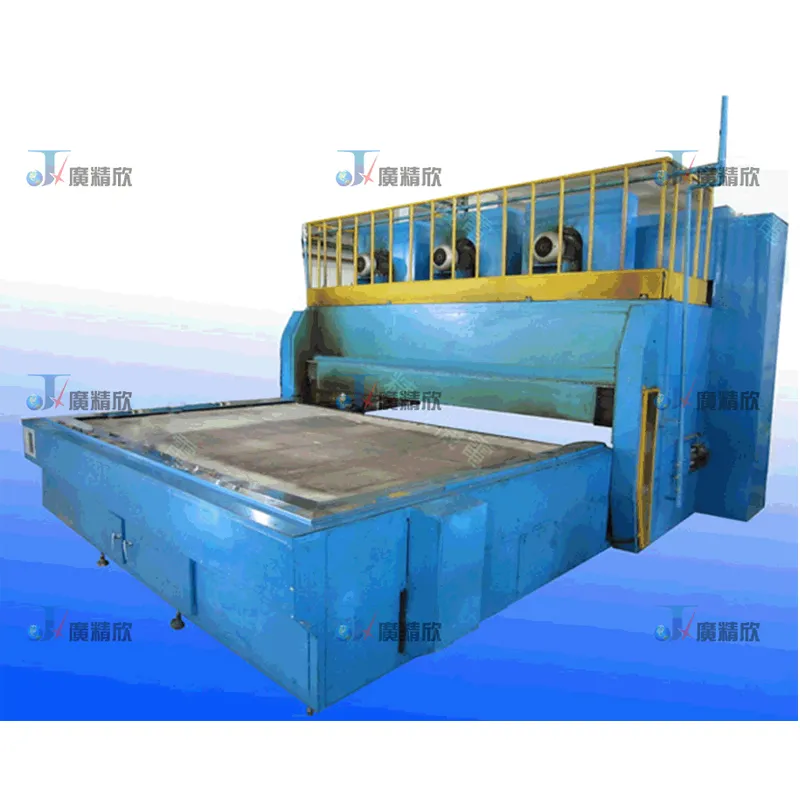

**Chongqing Guang Jingxin Technology Co., Ltd.** has developed an innovative **Internal Circulating Air Electrically Heating Oven** designed to revolutionize the production of thermoplastic materials, particularly in the automotive and textile industries. This advanced equipment combines compact design, energy efficiency, and precise temperature control to meet the demands of modern manufacturing. Below is a comprehensive overview of its features, applications, and technical specifications.

Product Overview

The **Internal Circulating Air Electrically Heating Oven** is a specialized system used primarily in the production of **automotive carpets** and other thermoplastic-coated materials. It integrates a base material tray, a heating oven, and an interactive chain mechanism to streamline the manufacturing process. The oven's design emphasizes **space efficiency** and **user-friendliness**, making it ideal for small to medium-sized production lines.

Key components include:

- Base Material Tray: Designed for secure placement of substrates during heating.

- Heating Oven: Utilizes electric heating tubes and air mixing technology for uniform heat distribution.

- Interactive Chain Mechanism: Facilitates seamless loading and unloading of trays with minimal manual intervention.

Core Advantages

This oven stands out due to its **energy-efficient heating**, **compact footprint**, and **reduced operational costs**. Here's a detailed breakdown of its benefits:

1. Compact and Space-Efficient Design

The oven's **small footprint** makes it suitable for facilities with limited space. Its modular design allows for easy integration into existing production lines, minimizing the need for extensive infrastructure modifications. This feature is particularly advantageous for **small to medium-sized manufacturers** looking to optimize their workspace.

2. Energy-Efficient Heating

By combining **electric heating tubes** with **air mixing technology**, the oven ensures **consistent heat distribution** while minimizing energy consumption. This dual approach not only reduces power costs but also enhances the **uniformity of thermoplastic coatings**, resulting in higher-quality outputs.

3. Easy Operation

The oven is engineered for **user-friendly operation**, requiring minimal training. With a **single-person operation** capability, it streamlines the loading and unloading process, significantly improving **labor efficiency**. The **interactive access mode** ensures smooth workflow without compromising safety.

4. Reduced Operational Costs

The system's **simple design** and **low maintenance requirements** contribute to long-term cost savings. By reducing labor and floor space expenses, it offers a **cost-effective solution** for manufacturers aiming to maximize profitability.

5. Consistent and High-Quality Production

The **air mixing heating mode** guarantees **uniform heating**, which is critical for achieving **durable and heat-resistant thermoplastic coatings**. This ensures that automotive carpets and other products meet stringent quality standards, even under extreme environmental conditions.

Applications Across Industries

The versatility of the **Internal Circulating Air Electrically Heating Oven** extends beyond automotive manufacturing. It is utilized in various sectors, including:

1. Automotive Industry

Automotive Carpets: Used for producing floor mats, trunk mats, and seat covers. The oven ensures **strong adhesion** of thermoplastic coatings, enhancing durability and comfort.

Interior Components: Applied to door panels, headliners, and soundproofing materials, where **consistent heating** is essential for proper molding.

Thermal Insulation: Helps create heat-resistant components that perform reliably in diverse climates.

2. Commercial Textile Production

Commercial Carpets and Rugs: Ideal for large-scale production of durable, easy-to-clean materials for public spaces.

Wall Coverings and Upholstery: Ensures effective bonding of thermoplastic coatings to substrates.

Protective Textile Coatings: Enhances water resistance and flame retardancy for industrial and outdoor applications.

3. Specialty Flooring and Insulation Products

Temporary Event Carpets: Provides quick processing for high-traffic event flooring.

Soundproofing Materials: Improves acoustic properties for commercial and automotive use.

Insulation Mats: Creates thermal and acoustic barriers for construction and automotive industries.

4. Aerospace and Transportation

Aircraft Interiors: Used for non-woven carpets and insulation materials requiring **lightweight and fire-resistant properties**.

Railway and Bus Flooring: Ensures durability and compliance with safety regulations.

5. Construction and Building Materials

Flooring Materials: Produces slip-resistant, easy-to-clean surfaces for commercial buildings.

Waterproof Membranes: Enhances water resistance for roofing and waterproofing applications.

Protective Film Coatings: Increases scratch resistance and UV protection for building materials.

6. Sports and Recreation Products

Sports Flooring: Creates impact-resistant mats for gyms and courts.

Outdoor Gear: Ensures weather-resistant coatings for tents and protective covers.

7. Packaging Materials

Thermoplastic Packaging Films: Used in food, medical, and industrial packaging to improve shelf life and protection.

Technical Specifications

| Parameter | Specification |

|---|---|

| Heating Method | Electric heating tubes with air mixing technology |

| Temperature Range | 100°C - 300°C (adjustable) |

| Dimensions (L x W x H) | 1200mm x 800mm x 1500mm |

| Power Supply | 380V, 50Hz |

| Energy Consumption | 2.5 kW/h (average) |

| Material Compatibility | Thermoplastic materials (e.g., PVC, PU, TPU) |

| Operational Efficiency | Single-person operation, 2-tray interactive access |

Company Background

**Chongqing Guang Jingxin Technology Co., Ltd.** is a leading manufacturer of industrial equipment specializing in **thermoplastic material processing solutions**. With years of experience in the field, the company is committed to delivering **innovative, high-quality machinery** that meets global industry standards.

For more information about the **Internal Circulating Air Electrically Heating Oven** or other products, visit the official website: **Product Page**. Explore the company's expertise at: **Chongqing Guang Jingxin Technology Co., Ltd.**.

References

1. National Institute of Standards and Technology (NIST) - Standards for industrial heating equipment and thermoplastic material processing.

2. Chongqing Guang Jingxin Technology Co., Ltd. - Official product documentation and technical specifications.

Keywords

car mat making machine, non woven carpet making machine, machine to make carpet