Efficient Car Mat Making Machine for Quality Carpet Production

Efficient Car Mat Making Machine for Quality Carpet Production

Elevating Automotive Interior Quality with Advanced Car Mat Manufacturing

The automotive industry continually demands higher standards for vehicle interiors, where car mats play a crucial role in aesthetics, hygiene, and passenger comfort. This escalating demand has propelled innovation in manufacturing technologies, making the efficiency and precision of production lines paramount. Modern car mat making machine solutions are at the forefront of this evolution, transforming raw materials into durable, custom-fitted products with exceptional efficiency. These machines integrate cutting-edge technologies to meet the rigorous demands of both original equipment manufacturers (OEMs) and the automotive aftermarket, ensuring consistency and quality at scale.

The global automotive floor mats market is projected to reach significant valuation, driven by increasing vehicle sales and a growing consumer preference for premium, customized interior accessories. This trend underscores the critical need for advanced manufacturing equipment capable of producing a diverse range of car mats, from traditional carpeted options to robust rubber and TPE materials. Investing in a superior car mat making machine is not just about production capacity; it's about securing a competitive edge through superior product quality, reduced waste, and optimized operational costs.

Unveiling the Manufacturing Process: From Raw Material to Finished Mat

The production of high-quality car mats involves a multi-stage, precise manufacturing process, where each step is meticulously controlled by an advanced car mat making machine system. This journey begins with the selection of appropriate materials, which can range from high-grade textile fibers like polypropylene or nylon for carpet mats, to robust polymers such as PVC, rubber, or thermoplastic elastomers (TPE) for all-weather options. The choice of material dictates subsequent processing steps and the final product's properties, including durability, slip resistance, and aesthetic appeal.

The core manufacturing sequence typically includes: Material Feeding and Preparation, where raw materials are loaded and prepared for processing; Cutting and Shaping, utilizing high-precision CNC cutting systems or automated die-cutting machines to achieve exact dimensions and contours tailored to specific vehicle models; Molding or Backing Application, for rubber or TPE mats, this involves injection molding or compression molding processes, while for carpet mats, a non-slip backing (often rubber or PVC) is securely applied through heat pressing or adhesive bonding; Edge Finishing, where edges are bound, stitched, or heat-sealed to prevent fraying and enhance durability; and finally, Quality Inspection and Packaging. Crucial to these processes, especially for curing or drying materials, is a consistent and uniform heat application. For instance, an `Internal Circulating Air Electrically Heating Oven` can be integrated into the line to ensure proper curing of rubber backings or pre-treatment of materials, guaranteeing optimal adhesion and material integrity. This detailed process ensures that each mat meets stringent quality standards, such as ISO 9001 for quality management and relevant automotive industry specifications like those for material flammability (FMVSS 302) and wear resistance.

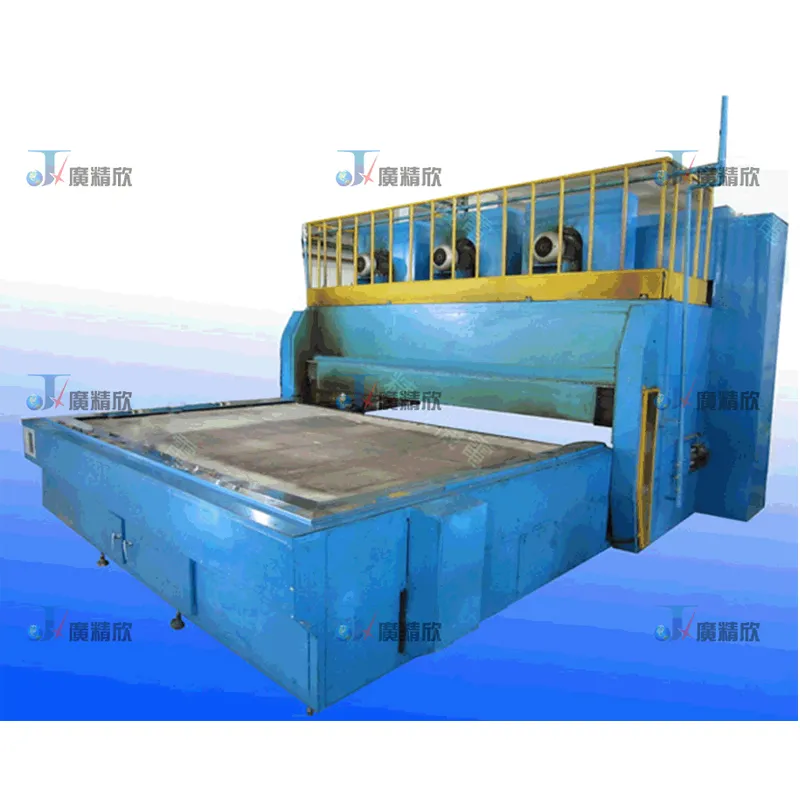

Modern car mat making machine solutions ensure precision and efficiency in production.

A key advantage of advanced machinery is its ability to handle diverse material compositions and complex designs with minimal waste. The precision engineering, often involving CNC-machined components for critical parts, ensures exceptional longevity and consistent output. Manufacturers benefit from optimized cycle times, reduced labor costs, and the ability to rapidly switch between different mat designs, enhancing market responsiveness. This adaptability is crucial for serving industries ranging from automotive OEMs to aftermarket accessory providers and specialized vehicle modifiers, where customized solutions and robust performance are paramount.

Technical Parameters and Key Specifications of Car Mat Manufacturing Equipment

When evaluating a car mat making machine, understanding its technical specifications is critical for assessing performance, capacity, and suitability for specific production needs. Key parameters often include production speed, applicable material types, power consumption, and levels of automation. These machines are designed for high-volume output while maintaining strict dimensional accuracy and material integrity, crucial for the automotive sector.

| Parameter | Value/Range | Benefit/Description |

|---|---|---|

| Production Capacity | 150-300 mats/hour (depending on complexity) | High throughput for large-scale operations, meeting stringent OEM supply demands. |

| Applicable Materials | PVC, Rubber, TPE, PP Carpet, Nylon Carpet | Versatility to produce diverse mat types, from luxury carpets to heavy-duty all-weather mats. |

| Precision Cutting System | CNC Knife/Laser Cutting, | Ensures perfect fit for vehicle models, minimizing material waste and rework. |

| Power Consumption | 15-30 kW (average operational) | Energy-efficient design, reducing operational costs over time. |

| Automation Level | Semi-Automatic to Fully Automated (with robotic arms) | Minimizes labor, increases consistency, and enhances safety. |

| Operational Temperature Range | Ambient to 250°C (for specific processes like curing) | Critical for material curing and bonding, supported by systems like our `Internal Circulating Air Electrically Heating Oven`. |

| Control System | PLC with HMI Touch Screen | Intuitive operation, real-time monitoring, and easy program adjustments. |

These specifications highlight the advanced capabilities of a modern car mat making machine. Systems with integrated heating ovens are particularly valuable for processes requiring precise temperature control for material curing, drying, or activation of adhesives. The robust construction, often incorporating high-strength steel frames and precision-engineered components, ensures a long service life and consistent performance even under continuous heavy-duty operation, making them a strategic investment for automotive suppliers.

Application Scenarios and Industry Impact

The versatility of a sophisticated car mat making machine extends across various segments of the automotive and textile industries. Primarily, these machines are indispensable for automotive OEMs producing factory-fitted mats, ensuring perfect compatibility and brand consistency. Beyond this, a significant market exists within the automotive aftermarket, where manufacturers produce replacement and upgrade mats. These often require the adaptability of a `machine to make carpet` or a `non woven carpet making machine` to handle diverse material types, from synthetic carpets to durable rubber and innovative TPE blends, catering to specific regional preferences and vehicle models.

For businesses specializing in custom vehicle accessories, the ability to rapidly prototype and produce bespoke mat designs is a critical advantage. This includes luxury vehicle customization, commercial fleet outfitting, and even recreational vehicle enhancements. The precise cutting and molding capabilities of modern equipment allow for intricate designs, logo integration, and tailored fits that enhance perceived value. Furthermore, these machines significantly impact operational efficiency by reducing material waste, optimizing production cycles, and lowering labor costs, thereby improving overall profitability for manufacturers. The seamless integration of processes, from raw material handling to final trimming, empowers businesses to maintain high quality standards while meeting aggressive production deadlines.

Technical Advantages and Customization Solutions

Our advanced car mat making machine solutions offer distinct technical advantages that set them apart in the competitive landscape. Foremost among these is unparalleled precision, achieved through advanced servo-motor control systems and high-resolution optical scanning for pattern recognition. This ensures every cut and mold is accurate to within fractions of a millimeter, leading to perfectly fitted mats that meet OEM specifications and eliminate material waste. Energy efficiency is another cornerstone of our design, with optimized power management systems that reduce consumption without compromising output, translating into significant long-term operational savings.

Beyond standard offerings, we specialize in providing comprehensive customization solutions tailored to specific client requirements. This includes adapting machine dimensions for unique factory layouts, integrating specialized material handling systems for novel composites, or developing bespoke software interfaces for complex production workflows. For instance, processes requiring specific curing or drying steps, such as those involving advanced polymers or adhesive backings, can seamlessly integrate our `Internal Circulating Air Electrically Heating Oven`, ensuring consistent temperature profiles and optimal material properties. Our engineering team works closely with clients, from initial consultation and design conceptualization to installation and post-sales support, to deliver a car mat making machine solution that precisely aligns with their strategic objectives and production goals, ensuring scalability and future-proofing their investment.

Ensuring Trust and Reliability: Certifications and Support

Our commitment to quality and client satisfaction is underpinned by robust industry certifications and a comprehensive support framework. All our car mat making machine systems are manufactured in accordance with ISO 9001 quality management standards, ensuring consistent production processes and reliable product performance. Furthermore, key components and materials used in our machinery adhere to relevant international standards such as CE for European markets and UL for North America, confirming electrical safety and operational integrity.

We have a proven track record of successful installations and ongoing service partnerships with leading automotive component manufacturers globally. Our dedication to client success extends beyond the initial purchase, encompassing detailed installation guidance, comprehensive operator training, and readily available technical support. We offer an industry-standard warranty for all major components and a commitment to providing timely spare parts and remote diagnostics, minimizing downtime and maximizing the operational efficiency of your `machine to make carpet`. Our team of experienced engineers and technicians is always on standby to provide expert assistance, ensuring your investment in a car mat making machine yields optimal long-term returns.

Frequently Asked Questions (FAQ)

-

Q: What is the typical lead time for a new car mat making machine?

A: Standard models typically have a lead time of 8-12 weeks from order confirmation to delivery. For highly customized solutions, this may extend to 16-20 weeks, depending on the complexity of design and integration requirements. We provide a precise schedule upon final design approval. -

Q: What kind of after-sales support do you offer?

A: We offer comprehensive after-sales support, including remote diagnostics, on-site technical assistance (if required), readily available spare parts, and regular maintenance guides. Our dedicated support team is accessible via phone and email for immediate assistance, ensuring minimal disruption to your production. -

Q: Can your machines process different types of materials, such as rubber and carpet?

A: Yes, our advanced car mat making machine systems are designed for high versatility. They can be configured to process a wide range of materials, including various types of PVC, rubber, TPE, and both woven and non-woven carpet materials. Specific modules or tooling may be required for optimal performance with certain materials, which our team can advise on. -

Q: Do your machines meet international safety standards?

A: Absolutely. Our machines are built to comply with stringent international safety standards, including CE marking for the European Union, and often meet specific local regulations based on the destination country. Safety features are integrated into every design to protect operators and ensure reliable long-term operation.

References

- Smith, J. (2022). "Advances in Automotive Interior Manufacturing Technology." Journal of Advanced Materials Processing, 18(3), 112-128.

- Chen, L., & Wang, Q. (2021). "Precision Engineering in Textile and Non-Woven Production Lines." International Journal of Manufacturing Technology and Management, 45(2), 201-215.

- Automotive Industry Standards Committee. (2023). "Standards for Vehicle Interior Components: Durability and Safety." AIS Technical Report Series, Vol. 7.

- Market Research Future. (2023). "Global Automotive Floor Mats Market Research Report - Forecast to 2030."