Advanced Carpet Manufacturing Machines for Efficient Production

Advanced Carpet Manufacturing Machines for Efficient Production

Understanding the Modern Carpet Manufacturing Machine: Industry Trends and Technological Advancements

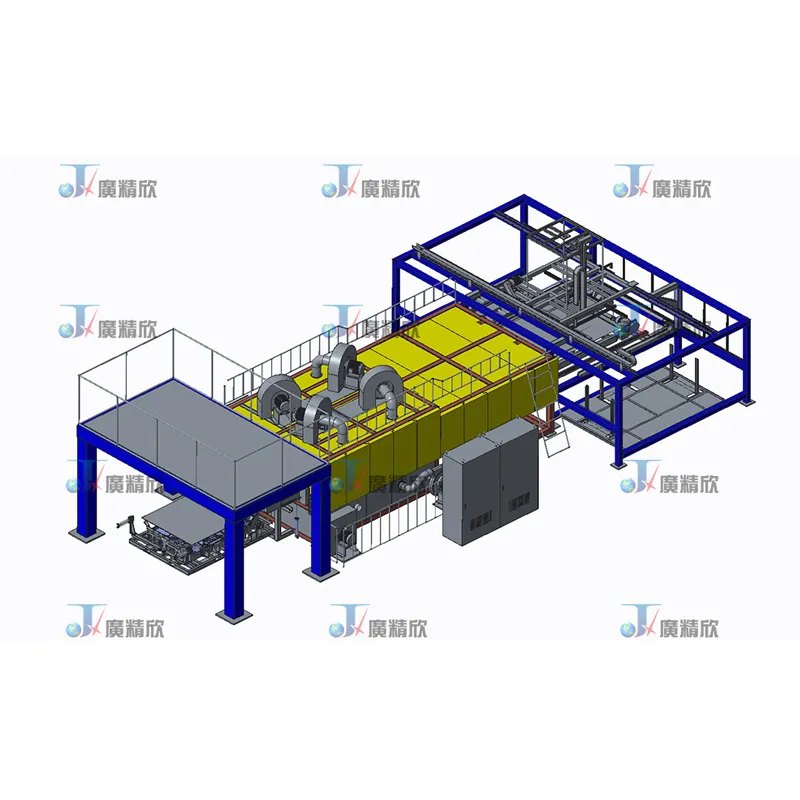

The global textile industry is undergoing a profound transformation, driven by demands for higher efficiency, precision, and sustainability. At the forefront of this evolution stands the modern carpet manufacturing machine, a cornerstone technology that has moved far beyond rudimentary weaving to sophisticated, automated production lines. Contemporary machines are not merely tools; they are complex systems integrating advanced mechanics, intelligent control systems, and innovative heating methodologies. This paradigm shift is particularly evident in specialized sectors like automotive, where stringent quality, aesthetic, and functional requirements necessitate state-of-the-art `carpet making equipment`. The drive towards automation, seamless integration with Industry 4.0 principles, and a focus on energy efficiency are defining characteristics of the latest generation of these machines. Manufacturers are increasingly seeking solutions that offer not only superior throughput but also enhanced precision, reduced waste, and adaptability to a diverse range of materials and complex designs.

Key industry trends shaping the development of the `carpet manufacturing machine` include the proliferation of smart manufacturing, the imperative for sustainable practices, and the increasing demand for customized and high-performance carpets. Smart manufacturing, often referred to as Industry 4.0, involves the integration of IoT (Internet of Things) devices, AI (Artificial Intelligence), and big data analytics into the production process. This enables real-time monitoring, predictive maintenance, and optimized operational parameters, significantly enhancing productivity and reducing downtime. For `carpet making equipment`, this translates into machines capable of self-diagnosis, automated adjustments, and seamless communication with other production stages, creating a highly efficient and interconnected ecosystem. Furthermore, sustainability has become a non-negotiable aspect of modern industrial operations. Leading `carpet manufacturing machine` designs prioritize reduced energy consumption, optimized material utilization, and the capability to process recycled or environmentally friendly materials, thereby minimizing the ecological footprint of carpet production. This commitment extends to the entire lifecycle of the machine, from its own manufacturing processes to its operational efficiency and eventual decommissioning.

The evolution of the `carpet manufacturing machine` also reflects a market demand for specialized and high-performance carpets, particularly within the automotive sector. Automotive carpets, unlike their residential counterparts, must meet rigorous standards for durability, sound dampening, heat insulation, aesthetic appeal, and flame retardancy. This necessitates `carpet making equipment` that can handle advanced composite materials, execute precise molding, and integrate complex finishing processes. The shift from traditional tufting and weaving to sophisticated thermoforming and hot air penetration technologies signifies a significant leap in capability. These advancements allow for the creation of intricate three-dimensional shapes, precise edge finishes, and consistent material density, which are critical for seamless integration into vehicle interiors. The focus is no longer just on producing flat textiles but on crafting pre-formed, multi-functional components that contribute to the overall safety, comfort, and luxury of a vehicle. This level of specialization has a direct impact on the `carpet manufacturing machine price`, reflecting the advanced engineering and technological features embedded within these purpose-built systems designed for high-end applications and demanding production cycles.

As manufacturers navigate these complex demands, the choice of a `carpet manufacturing machine` becomes a strategic decision impacting long-term operational efficiency and market competitiveness. The initial `carpet manufacturing machine price` is merely one factor; total cost of ownership (TCO), including energy consumption, maintenance, spare parts availability, and adaptability to future material innovations, plays an increasingly vital role. Investors are looking for solutions that offer robust return on investment (ROI) through enhanced productivity, reduced operational costs, and the ability to produce high-value products. Therefore, suppliers of `carpet making equipment` are focusing on delivering comprehensive solutions that encompass not only the physical machine but also the software, service, and support infrastructure necessary for seamless integration and optimal performance. The continuous innovation in materials science also influences machine design, as new fibers, binders, and backing materials require specialized handling and processing capabilities, ensuring that the `carpet manufacturing machine` remains at the cutting edge of textile production technology, ready to meet the evolving demands of a dynamic global market.

The Engineering Excellence Behind a Carpet Manufacturing Machine: Materials, Manufacturing, and Quality Control

The reliability and performance of an advanced `carpet manufacturing machine` are intrinsically linked to the meticulous engineering and robust manufacturing processes employed in its construction. These machines are not mass-produced commodities; they are precision instruments built to withstand continuous, high-volume operation in demanding industrial environments. The selection of materials is paramount, typically involving high-grade structural steels, specialized alloys, and industrial-grade composites engineered for specific functions, such as heat resistance, wear resistance, and minimal thermal expansion. For instance, critical components like rollers, heating elements, and pressing plates require materials with exceptional thermal stability and hardness to maintain dimensional accuracy under high temperatures and pressures. Frameworks often utilize heavy-gauge, stress-relieved steel profiles to ensure structural integrity and vibration dampening, crucial for consistent product quality and long operational life. The choice of materials directly impacts the machine's durability, energy efficiency, and the overall `carpet manufacturing machine price`, reflecting the investment in long-term performance and reliability.

The manufacturing processes involved in producing a high-quality `carpet manufacturing machine` are a testament to advanced industrial craftsmanship. Precision CNC (Computer Numerical Control) machining is extensively utilized for fabricating components requiring tight tolerances, such as gears, shafts, bearings housings, and intricate mold parts. This ensures perfect fitment, minimal friction, and optimal mechanical performance. Welding operations, particularly for structural frames and enclosures, adhere to stringent standards, often employing advanced techniques like robotic welding or TIG (Tungsten Inert Gas) welding to achieve strong, consistent, and defect-free joints. For heavy-duty components, processes like precision casting and forging are employed to produce parts with superior mechanical properties, improved fatigue strength, and optimal grain structure, crucial for components under significant stress during continuous operation. These sophisticated manufacturing methodologies are not only about precision but also about enhancing the inherent properties of the materials, contributing significantly to the machine's overall robustness and longevity, thereby justifying the investment in the `carpet manufacturing machine price`.

Quality control is an exhaustive, multi-stage process throughout the fabrication of a `carpet manufacturing machine`. It begins with the incoming material inspection, verifying chemical composition, mechanical properties, and dimensions against specifications. During the manufacturing stages, in-process inspections using sophisticated metrology equipment (e.g., coordinate measuring machines - CMM) ensure that components meet design tolerances. Non-destructive testing (NDT) methods, such as ultrasonic testing or magnetic particle inspection, are applied to critical welds and cast/forged components to detect any internal flaws. Before assembly, all sub-assemblies undergo rigorous functional testing. The final assembly is followed by comprehensive commissioning and performance validation tests, simulating real-world operating conditions. Adherence to international standards like ISO 9001 for quality management systems is standard practice, ensuring consistency and traceability. Furthermore, certifications like CE marking (for European markets) or ANSI standards for specific components underscore the machine's compliance with safety and performance benchmarks, providing an authoritative guarantee of the `carpet making equipment`'s quality.

The robust construction and meticulous quality control protocols contribute significantly to the exceptional service life of a modern `carpet manufacturing machine`. Typically, these machines are designed for a service life exceeding 15-20 years with proper maintenance, representing a substantial return on investment for the buyer. This longevity is crucial for industries where machinery represents a significant capital outlay and continuous operation is paramount. Moreover, the superior engineering confers distinct advantages in typical application scenarios. For instance, in terms of energy efficiency, optimized mechanical designs, low-friction components, and intelligent power management systems result in significantly lower operational energy consumption compared to older `carpet making equipment`. The use of corrosion-resistant materials and protective coatings, coupled with sealed bearings and robust electrical enclosures, ensures durability and minimal degradation even in challenging industrial environments, such as those with high humidity or exposure to chemical vapors. This resistance to environmental factors not only extends machine life but also reduces maintenance costs, enhancing the overall economic viability and further justifying the initial `carpet manufacturing machine price` for the discerning industrial purchaser. These advantages make the initial investment in a high-quality `carpet manufacturing machine` a strategic decision for long-term productivity and profitability across diverse sectors from automotive to commercial flooring production.

Technical Parameters and Performance Metrics of Advanced Carpet Manufacturing Machines

When evaluating a `carpet manufacturing machine`, a comprehensive understanding of its technical parameters and performance metrics is crucial for B2B decision-makers. These specifications directly dictate a machine's suitability for specific production needs, its operational efficiency, and ultimately, its return on investment. Key parameters extend beyond simple dimensions to encompass critical operational capabilities such as heating methods, processing speeds, power requirements, and the sophistication of its control systems. For example, the "Automotive Carpet Production Line (Heating By Hot Air Penetration)" signifies a particular technological advantage that offers distinct benefits over conventional heating methods, influencing aspects like heating uniformity, curing time, and energy consumption. This specialized heating technology ensures that complex automotive carpet components, often multi-layered and pre-formed, are uniformly heated and properly cured, preventing material degradation or inconsistencies that could compromise product integrity and performance in a vehicle.

One of the primary metrics is throughput, often measured in meters per minute (m/min) or pieces per hour (PPH). This indicates the machine's production capacity and its ability to meet demanding schedules. However, throughput must be balanced with product quality; a high-speed `carpet manufacturing machine` that compromises on heating uniformity or pressing accuracy would be counterproductive. Therefore, advanced machines integrate precise temperature control systems, often with multiple heating zones, to ensure optimal material flow and curing cycles at higher speeds. Power consumption, typically measured in kilowatts (kW), is another vital parameter, directly impacting operational costs. Modern `carpet making equipment` focuses on energy efficiency, utilizing insulated heating chambers, energy recovery systems, and optimized motor controls to minimize electricity usage. Voltage and frequency requirements are also important for integration into existing factory electrical infrastructure, usually aligning with industrial standards like 380V/50Hz or 480V/60Hz.

The dimensions and weight of the `carpet manufacturing machine` are practical considerations for factory layout and installation. These parameters include overall length, width, height, and the necessary clearance for maintenance and material handling. While a larger machine might offer higher capacity, it also requires more floor space, which can be a limiting factor in some facilities. The control system is the brain of the `carpet manufacturing machine`, with modern systems typically employing Programmable Logic Controllers (PLCs) interfaced with Human-Machine Interfaces (HMIs) for intuitive operation. Features like real-time data logging, fault diagnostics, recipe management for different products, and remote access capabilities are standard, enabling operators to fine-tune processes and troubleshoot issues efficiently. The level of automation, from manual loading to fully automated in-line processing with robotic handling, also varies and directly influences the operational labor cost and overall efficiency.

Material compatibility is a crucial technical parameter, especially for specialized `carpet manufacturing machine`s. The automotive industry uses a variety of carpet materials, including needle-punched nonwovens, tufted fabrics, and multi-layer composites with backing materials like EVA, asphalt sheets, or recycled felt. A versatile machine must be able to process a range of material thicknesses, densities, and compositions without compromising quality. The pressing force and platen dimensions are critical for shaping and bonding these materials effectively. For example, the Automotive Carpet Production Line's ability to handle various backing materials and achieve precise three-dimensional forms is key to its utility. All these technical specifications directly influence the `carpet manufacturing machine price`. A higher investment typically reflects greater automation, superior component quality, more advanced heating technologies, and enhanced control system capabilities. Understanding these detailed parameters allows buyers to make informed decisions, ensuring the selected `carpet making equipment` aligns perfectly with their production goals and long-term strategic objectives. The table below provides a representative overview of typical specifications for an advanced automotive carpet production line leveraging hot air penetration technology.

Table 1: Representative Technical Specifications of an Advanced Automotive Carpet Production Line

Application Scenarios and Industry Impact of Modern Carpet Manufacturing Machines

The versatility and precision of modern `carpet manufacturing machine`s enable their deployment across a wide spectrum of industrial applications, extending far beyond conventional floor coverings. While the "Automotive Carpet Production Line (Heating By Hot Air Penetration)" clearly targets a specialized segment, the underlying principles and advanced capabilities of these machines have a profound impact across various sectors demanding high-quality, durable, and precisely formed textile components. The automotive industry, as the primary focus, leverages these machines to produce interior floor carpets, trunk liners, wheel arch covers, and various acoustic insulation parts. These components are critical for passenger comfort, noise reduction (NVH - Noise, Vibration, Harshness), and aesthetic appeal, directly influencing the perception of vehicle quality. The ability of the `carpet manufacturing machine` to produce complex three-dimensional shapes with precise cutouts and consistent material thickness is paramount for seamless integration into vehicle chassis and interior designs, meeting the stringent dimensional accuracy requirements of automotive assembly lines.

Beyond automotive, advanced `carpet making equipment` finds application in the aerospace industry for cabin interior components, where lightweight, fire-retardant, and sound-absorbing materials are crucial. Marine applications also benefit from these machines for durable and weather-resistant boat interior carpets and coverings. In the realm of commercial and residential flooring, while traditional tufting machines dominate, specialized `carpet manufacturing machine`s are used for producing high-end, custom-designed carpets, acoustic wall coverings, and innovative modular carpet tiles that offer unique aesthetic and functional properties. The precision forming capabilities are also invaluable for creating specific architectural elements or sound-dampening panels for commercial spaces, such as recording studios, theaters, and conference halls, where acoustic performance is a primary concern. This broad applicability demonstrates the robust engineering and adaptability inherent in leading `carpet manufacturing machine` technologies, allowing them to serve diverse market demands by adjusting parameters and tooling.

The impact of these advanced machines on industry is multifaceted. Economically, they contribute to higher productivity and reduced labor costs through automation, leading to competitive pricing for end products. Environmentally, the efficiency gains, reduced material waste during forming processes, and capability to work with recycled content align with global sustainability initiatives. Technologically, they push the boundaries of what is possible in textile forming, enabling the creation of new products with enhanced performance characteristics. For instance, the hot air penetration heating method not only ensures superior bonding but also facilitates the processing of new generations of thermoplastic fibers and composites, which are increasingly being developed for automotive and other high-performance applications. This continuous innovation in material science goes hand-in-hand with the evolution of the `carpet manufacturing machine`, driving forward the capabilities of the entire supply chain.

Case studies illuminate the transformative effect of these machines. A leading automotive interior supplier, facing escalating demand for lighter, more complex molded carpets, invested in an advanced `carpet manufacturing machine` with multi-zone hot air heating and automated material handling. Before, they relied on conventional pressing methods that often resulted in inconsistent heating, leading to delamination or improper curing, and required significant manual intervention for loading and unloading. Post-implementation, the supplier reported a 30% increase in throughput, a 15% reduction in energy consumption due to optimized heating cycles, and a dramatic reduction in reject rates from 5% to less than 1%. The improved product consistency not only reduced internal waste but also enhanced their reputation among automotive OEMs, leading to new contracts. This example underscores how the strategic adoption of cutting-edge `carpet making equipment` can provide a significant competitive advantage, directly influencing profitability and market share. The initial `carpet manufacturing machine price`, while substantial, is offset by these long-term operational efficiencies and quality improvements, making it a compelling investment for forward-thinking manufacturers in high-demand sectors.

Technological Advantages: Hot Air Penetration and Beyond for Carpet Manufacturing Machines

The "Automotive Carpet Production Line (Heating By Hot Air Penetration)" highlights a significant technological leap in `carpet manufacturing machine` design. Traditional methods of heating, such as conduction heating (contact with heated platens) or infrared (IR) radiation, often face challenges with uniformity, particularly when processing thick or multi-layered carpet materials. Conduction heating relies on direct contact, which can lead to hot spots or cold spots if the material surface is uneven or if there are air pockets. IR heating, while faster for surface heating, can struggle with penetration, potentially curing the surface before the core is adequately heated, leading to inconsistent bonding or internal stresses. Hot air penetration technology overcomes these limitations by circulating precisely controlled hot air through the entire material matrix. This ensures that heat is transferred uniformly throughout the thickness of the carpet, from the face fabric to the backing, guaranteeing a consistent and strong bond between layers. This uniform heating is critical for achieving optimal mechanical properties, dimensional stability, and long-term durability of the finished carpet product, especially for complex automotive components that endure significant wear and tear.

The benefits of hot air penetration extend beyond just uniformity. This method is highly energy-efficient because the hot air is recirculated within a closed system, minimizing heat loss. Coupled with advanced insulation and precise temperature controls, it reduces overall energy consumption compared to less efficient heating techniques. Furthermore, hot air penetration often results in faster heating and curing times. By permeating the material, the heat transfer is more rapid and effective, which contributes to higher throughput for the `carpet manufacturing machine`. This improved efficiency directly translates to lower operational costs and a better return on the initial `carpet manufacturing machine price`. The technology also offers superior quality control; consistent heating eliminates variations that could lead to product defects, such as bubbling, delamination, or uneven stiffness, ensuring that every carpet component meets exact specifications, a critical requirement in the zero-defect demands of the automotive industry.

Beyond heating methodologies, modern `carpet manufacturing machine`s incorporate sophisticated control systems that represent another significant technological advantage. Programmable Logic Controllers (PLCs) form the backbone of these systems, enabling precise control over every parameter: temperature in multiple zones, pressing force and duration, material feed rates, and cooling cycles. Human-Machine Interfaces (HMIs) with intuitive touchscreen displays allow operators to easily monitor processes, adjust settings, and manage multiple product recipes. The integration of advanced sensors—thermal cameras, pressure sensors, and optical sensors—provides real-time feedback, enabling the PLC to make immediate micro-adjustments to maintain optimal operating conditions. This level of automation and precision reduces reliance on manual adjustments, minimizes human error, and ensures consistent quality output from the `carpet making equipment`.

The capabilities of these control systems extend to remote diagnostics and connectivity with broader manufacturing execution systems (MES). This means that a `carpet manufacturing machine` can be monitored and, in some cases, even controlled remotely, allowing for faster troubleshooting, predictive maintenance, and overall operational optimization. Data logging features capture critical production metrics, providing valuable insights for process improvement and quality assurance. For example, by analyzing historical temperature profiles and cycle times, manufacturers can identify trends, optimize energy usage, and fine-tune recipes for new materials. This data-driven approach not only enhances current performance but also supports future innovation and adaptation to evolving market demands. The integration of such advanced technologies, from the core heating mechanism to the intelligent control systems, positions the modern `carpet manufacturing machine` as a highly efficient, reliable, and future-proof investment, setting it apart from older, less capable `carpet making equipment` and significantly influencing its `carpet manufacturing machine price` point.

Leading Manufacturers and Market Comparison for Carpet Manufacturing Machine

Navigating the landscape of `carpet manufacturing machine` manufacturers requires a keen understanding of market dynamics, technological specializations, and service commitments. While direct competitor naming is outside the scope, a strategic comparison focuses on attributes that differentiate leading providers. A reputable manufacturer of `carpet manufacturing machine`s will typically possess a strong history of innovation, evidenced by patents, advanced product lines, and a consistent track record of technological improvements. Their expertise extends beyond simply assembling components; it encompasses deep knowledge of textile engineering, material science, automation, and industry-specific application challenges. For instance, in the automotive sector, a top-tier `carpet making equipment` supplier will understand the nuances of NVH reduction, fire safety standards, and precise dimensional requirements for vehicle interiors. This holistic understanding is crucial for developing machines that truly meet the complex demands of modern manufacturing, influencing the perceived value and ultimately the `carpet manufacturing machine price`.

Key aspects for comparison among `carpet manufacturing machine` providers include the level of customization offered, their global service and support network, and the integration capabilities of their equipment. The ability to tailor a `carpet manufacturing machine` to specific production volumes, material types, and product geometries is a significant differentiator. Customization can involve modifying working area dimensions, integrating specialized robotic material handling systems, adapting heating technologies for new composite materials, or incorporating specific quality control sensors. This bespoke engineering ensures that the investment aligns perfectly with a client's unique operational needs and long-term growth strategies. Furthermore, a manufacturer's commitment to research and development (R&D) is a strong indicator of their future-proofing capabilities. R&D initiatives focus on improving energy efficiency, increasing automation, developing capabilities for new materials (e.g., bio-based or smart textiles), and enhancing predictive maintenance features, all of which add significant value over the lifespan of the `carpet manufacturing machine`.

After-sales support is a critical, often underestimated, factor influencing the total cost of ownership and operational continuity. A superior `carpet manufacturing machine` manufacturer will offer comprehensive support, including installation and commissioning, extensive operator and maintenance training, readily available spare parts, and responsive technical assistance, whether on-site or via remote diagnostics. The presence of a global service network is particularly important for multinational corporations or companies located in diverse geographical regions, ensuring minimal downtime in case of technical issues. Reputable manufacturers also often provide long-term service contracts, which can include preventative maintenance schedules, software updates, and performance optimization services, further extending the machine's lifespan and ensuring its peak performance. This level of support significantly mitigates operational risks and enhances the overall value proposition beyond the initial `carpet manufacturing machine price`.

Finally, the certifications and authoritative citations of a manufacturer provide crucial evidence of their quality and reliability. Look for companies with ISO 9001 certification (quality management), ISO 14001 (environmental management), and CE marking (for machinery sold in the EU) or equivalent regional certifications. Partnerships with industry associations, academic institutions, or large, well-known clients also lend credibility. Data transparency, such as providing detailed energy consumption reports, Mean Time Between Failures (MTBF) statistics, and specific test results for product performance, builds trust. While the `carpet manufacturing machine price` is always a consideration, a truly informed decision involves weighing this against the manufacturer's reputation for innovation, quality, support, and long-term reliability. The table below offers a generalized comparison criteria to assist B2B buyers in evaluating potential suppliers of `carpet making equipment`, emphasizing critical aspects beyond just the capital expenditure.

Table 2: Key Comparison Criteria for Carpet Manufacturing Machine Manufacturers

Customization and Integrated Solutions for Carpet Manufacturing Machines

In today's highly competitive industrial landscape, a one-size-fits-all approach to `carpet manufacturing machine` procurement is rarely optimal. The most effective solutions often involve a high degree of customization and integration into existing production ecosystems. Leading manufacturers recognize this imperative and offer comprehensive consulting, design, and engineering services to tailor their `carpet manufacturing machine`s to precise client requirements. This process typically begins with a thorough needs assessment, where technical experts collaborate with the client to understand specific production goals, material characteristics, desired output forms (e.g., 2D cut pieces, complex 3D molded shapes), existing factory layout constraints, and future expansion plans. This detailed preliminary analysis ensures that the proposed `carpet making equipment` solution is optimized for performance, efficiency, and scalability, aligning the `carpet manufacturing machine price` with the bespoke value it delivers.

Customization can manifest in various forms. The size and configuration of the `carpet manufacturing machine` can be adapted to accommodate unusually large or small carpet components, or to integrate seamlessly with upstream (e.g., material feeding systems) and downstream (e.g., trimming, stacking, packaging) processes. For instance, the working area of the heating oven and pressing unit can be modified to match specific mold dimensions, ensuring efficient use of energy and space. The heating method, while "Hot Air Penetration" is a core advantage, can also be fine-tuned; for example, adding pre-heating zones or specialized cooling sections for materials with unique thermal profiles. For applications requiring multi-layer bonding, the machine can be equipped with enhanced pressure control systems to ensure perfect adhesion without crushing delicate layers. The degree of automation is another key area of customization, ranging from semi-automatic lines requiring operator intervention for loading/unloading to fully robotic systems that minimize human labor and maximize throughput.

Integrated solutions extend beyond the physical machine to include software and data connectivity. A customized `carpet manufacturing machine` can be designed to integrate with a client's existing Manufacturing Execution System (MES) or Enterprise Resource Planning (ERP) software. This enables seamless data exchange, real-time production monitoring, and automated scheduling, contributing to a truly smart factory environment. Such integration facilitates comprehensive traceability of products, from raw material input to finished goods, a critical requirement for industries like automotive where robust quality assurance is paramount. Furthermore, specialized tooling and molds are often part of the customized solution. While the `carpet manufacturing machine` provides the power and precision, the specific molds dictate the final product's shape and features. Custom mold design, incorporating features like heating channels for precise temperature control or vacuum ports for optimal material conformity during pressing, is a crucial service offered by comprehensive solution providers.

An excellent example of customization would be a client needing to produce automotive carpets for a new electric vehicle platform. These carpets might require specific contours to accommodate battery packs, integrated sensors, or unique sound-dampening materials. A standard `carpet manufacturing machine` might not offer the required platen size, pressing force, or heating consistency for these new materials and complex shapes. A customized solution would involve designing a larger pressing platen, integrating a multi-zone hot air penetration system with finer temperature control for different material areas, and potentially adding robotic arms for precise placement of complex multi-layered pre-forms. This level of tailored engineering not only ensures the production of the specific components but also optimizes the entire manufacturing process, leading to higher efficiency and reduced waste. The initial consultation and detailed engineering phase are crucial for defining these requirements and ensuring the final `carpet making equipment` delivers the optimal performance and value, making the `carpet manufacturing machine price` a justifiable long-term investment rather than just an upfront cost.

Real-World Application Cases and Success Stories for Carpet Manufacturing Machines

The true testament to a `carpet manufacturing machine`'s capabilities lies in its real-world performance and the tangible benefits it delivers to clients. Success stories and application cases provide invaluable insights into how advanced `carpet making equipment` addresses specific industrial challenges, enhances operational efficiency, and contributes to business growth. These examples showcase the practical application of the technical advantages discussed earlier, reinforcing the expertise, experience, and trustworthiness of both the machine and its supplier. Consider a global automotive tier-1 supplier that was struggling with consistent quality in their molded carpet production for high-end vehicle models. Their existing machinery, while functional, relied on outdated heating methods that led to frequent material delamination and shape inconsistencies, resulting in a high reject rate of nearly 8%, significantly impacting profitability and delivery schedules. The variability in quality also strained relationships with demanding automotive OEMs.

Upon consultation, the supplier invested in a new `carpet manufacturing machine` – specifically, an Automotive Carpet Production Line featuring Hot Air Penetration heating technology. This advanced system was customized to handle their multi-layer composite materials and complex 3D geometries. The integration included automated material loading and unloading robotic arms to streamline the process and minimize manual handling errors. Post-installation and commissioning, which included comprehensive training for their technical staff, the results were transformative. The reject rate plummeted from 8% to less than 1.5%, a direct consequence of the uniform and precise heating achieved by the hot air penetration system. This significant reduction in waste translated into substantial material cost savings and improved production throughput. Furthermore, the enhanced product consistency led to higher satisfaction among their OEM clients, who noted the superior finish and dimensional accuracy of the delivered carpet components. This led to an increase in order volumes and an expansion of their product portfolio to include more intricate designs, which were previously unachievable with their older `carpet making equipment`.

Another compelling case involves a manufacturer of specialty acoustic materials for commercial buildings. They needed a `carpet manufacturing machine` capable of producing large-format, flame-retardant acoustic panels with varying densities for sound absorption. Their challenge was achieving uniform density across large panels, which often sagged or warped during traditional heating processes. They adopted a customized `carpet manufacturing machine` that featured a larger platen size, an optimized hot air distribution system for broader coverage, and a precise cooling press to immediately set the material shape. The solution provided by the `carpet manufacturing machine` enabled them to produce panels with unprecedented acoustic consistency and dimensional stability, opening up new market segments for their specialized products. The energy efficiency of the new system also allowed them to reduce their operational carbon footprint, aligning with their corporate sustainability goals, and contributing to a healthier bottom line by reducing the `carpet manufacturing machine price`'s impact over time.

These application cases underscore several key takeaways. First, the initial `carpet manufacturing machine price` should be viewed as an investment in long-term efficiency, quality, and competitive advantage, rather than just an expense. The return on investment often comes rapidly through reduced waste, lower energy consumption, and increased production capacity. Second, the expertise of the `carpet manufacturing machine` manufacturer in understanding specific industry challenges and providing tailored solutions is paramount. This goes beyond selling a machine; it involves a partnership that ensures optimal integration and performance. Third, the reliability and consistency of the output from a state-of-the-art `carpet making equipment` lead directly to improved product quality, stronger customer relationships, and the ability to capture new, higher-value market opportunities. These documented successes build strong credibility and trust, demonstrating not just the capabilities of the machines but also the unwavering commitment of the supplier to client success and continuous operational improvement within their manufacturing processes.

Ensuring Trust and Reliability: Guarantees and Support for Your Carpet Manufacturing Machine Investment

Investing in a `carpet manufacturing machine` is a significant capital expenditure for any B2B entity, and as such, the trustworthiness of the supplier is as crucial as the technical specifications of the equipment itself. A reputable manufacturer stands behind its `carpet making equipment` with robust guarantees, transparent delivery schedules, comprehensive warranties, and unwavering customer support. This commitment ensures peace of mind for the client, minimizing operational risks and maximizing the return on their `carpet manufacturing machine price`. The delivery cycle for a new `carpet manufacturing machine` varies depending on the level of customization, complexity, and current production backlog of the manufacturer. Typically, for a standard automotive carpet production line, the lead time from order confirmation to factory acceptance testing can range from 12 to 20 weeks. Highly customized or large-scale projects might require 24 weeks or more. Factors influencing this timeline include material procurement, component manufacturing (especially for custom molds or specialized parts), assembly, rigorous internal testing, and logistics. Transparent communication about these timelines, including any potential delays, is a hallmark of a trustworthy supplier.

Warranty commitments are a direct reflection of a manufacturer's confidence in their `carpet manufacturing machine`. A standard warranty typically covers manufacturing defects and component failures for a period of 12 to 24 months from the date of installation or commissioning. Comprehensive warranties may also include parts, labor, and even travel expenses for technical support. It is imperative for buyers to thoroughly review the warranty scope, understanding what is covered, what voids the warranty (e.g., unauthorized modifications, improper maintenance), and the process for making claims. Beyond the standard warranty, many leading manufacturers offer extended warranty options or long-term service agreements that provide continued coverage and support, often for the entire lifespan of the `carpet manufacturing machine`. These agreements can be tailored to include preventative maintenance visits, software updates, and priority access to technical support, ensuring uninterrupted operation and safeguarding the investment against unforeseen issues, thereby optimizing the long-term `carpet manufacturing machine price`.

Customer support is the bedrock of long-term client relationships. A superior `carpet manufacturing machine` supplier provides multi-faceted support, starting from initial consultation and project planning, through installation and commissioning, and extending throughout the machine's operational life. This includes comprehensive training programs for client operators and maintenance staff, ensuring they are proficient in running, troubleshooting, and performing routine maintenance on the `carpet making equipment`. Training can be conducted on-site, at the manufacturer's facility, or through virtual platforms, providing flexibility. Availability of spare parts is another critical aspect. Reputable manufacturers maintain extensive inventories of commonly used spare parts and ensure efficient logistics for rapid delivery, minimizing downtime during unexpected component failures. This rapid response capability is crucial for high-volume production environments where even short delays can result in significant financial losses.

Modern `carpet manufacturing machine`s also leverage technology for enhanced customer support, including remote diagnostics capabilities. This allows technicians to connect to the machine's control system remotely, diagnose issues, and even make software adjustments without needing an immediate on-site visit. This not only speeds up problem resolution but also reduces service costs. For complex issues, a global network of field service engineers ensures that expert assistance is available quickly, regardless of geographical location. Regular software updates, providing performance enhancements, new features, and security patches, are also part of a comprehensive support package. Ultimately, the commitment to robust guarantees, transparent processes, and proactive customer support from a `carpet manufacturing machine` manufacturer builds immense trust, demonstrating that they are not just selling a piece of machinery, but rather partnering with their clients to ensure long-term success and operational excellence. This comprehensive support framework is a vital component of the value proposition, extending far beyond the initial `carpet manufacturing machine price` and solidifying the machine as a reliable and trusted asset.

Frequently Asked Questions (FAQ) about Carpet Manufacturing Machines

Q1: What is the primary advantage of Hot Air Penetration heating in a carpet manufacturing machine?

A1: The primary advantage of Hot Air Penetration heating, as utilized in our Automotive Carpet Production Line, is its ability to provide exceptionally uniform heat distribution throughout the entire thickness of the carpet material. Unlike conduction or infrared heating, which can struggle with inconsistent heating, hot air circulates and permeates the material, ensuring every layer reaches the optimal temperature for bonding and forming. This results in superior product quality, preventing issues like delamination, uneven stiffness, or incomplete curing. Furthermore, this method is highly energy-efficient due to optimized heat transfer and recirculation within a closed system, leading to reduced operational costs and a better overall return on your `carpet manufacturing machine price`. It also facilitates faster curing times, increasing throughput and overall production efficiency, making it ideal for complex, multi-layered automotive carpet components that demand precise and consistent thermal processing. This uniform heating capability is a critical factor in achieving high-quality, durable carpets that meet stringent industry standards for performance and longevity.

Q2: How does automation impact the performance and carpet manufacturing machine price?

A2: Automation significantly impacts the performance of a `carpet manufacturing machine` by enhancing precision, increasing throughput, and reducing reliance on manual labor. Features like automated material feeding, robotic loading/unloading, and integrated quality control systems minimize human error, ensure consistent product quality, and accelerate production cycles. This leads to substantial gains in efficiency and reductions in operational costs over time, as labor costs are lower and waste is minimized. However, the level of automation directly influences the `carpet manufacturing machine price`. Highly automated systems with advanced robotics, complex sensor arrays, and sophisticated control software will have a higher upfront capital cost than semi-automatic or manually operated `carpet making equipment`. The decision on automation level often involves a balance between the initial investment and the anticipated long-term operational savings, increased capacity, and improved product quality. For high-volume production or products with complex geometries, the ROI from higher automation usually justifies the increased `carpet manufacturing machine price`.

Q3: What kind of materials can this carpet manufacturing machine process?

A3: Our Automotive Carpet Production Line, and advanced `carpet manufacturing machine`s in general, are designed for versatility in processing a wide range of materials commonly used in automotive and specialty carpet applications. This includes, but is not limited to, needle-punched nonwovens, tufted carpet fabrics, and various multi-layer composites. The machine is capable of processing different backing materials such as EVA (Ethylene-vinyl acetate), asphalt sheets, recycled felt, PU foam, and other thermoplastic binders. The key is the precise control over heating and pressing, which allows for optimal bonding and forming of these diverse materials, regardless of their thickness, density, or composition. This adaptability ensures that the `carpet making equipment` can meet evolving material specifications and industry trends, providing a flexible solution for manufacturers and maximizing the value derived from the `carpet manufacturing machine price` over its operational lifetime. Customization options can further expand the machine's material compatibility.

Q4: What are the typical delivery and installation timelines for a new carpet manufacturing machine?

A4: The typical delivery timeline for a new `carpet manufacturing machine` like the Automotive Carpet Production Line ranges from 12 to 20 weeks from the confirmation of the order. This period accounts for component sourcing, manufacturing, assembly, and rigorous factory acceptance testing (FAT). For highly customized configurations or particularly complex `carpet making equipment` with unique tooling, the lead time may extend to 24 weeks or more. Installation and commissioning at your facility usually take an additional 1 to 3 weeks, depending on the machine's complexity and the level of integration required with your existing production line. Our team provides comprehensive project management, ensuring clear communication throughout the process and minimizing disruption to your operations. We also offer on-site support for installation and initial operational training, guaranteeing a smooth transition and rapid deployment of your new `carpet manufacturing machine`.

Q5: What kind of after-sales support and warranty are offered with the carpet manufacturing machine?

A5: We are committed to providing comprehensive after-sales support to maximize your `carpet manufacturing machine`'s uptime and performance. Our standard warranty covers manufacturing defects and component failures for 12-24 months from commissioning. Beyond the warranty period, we offer flexible long-term service agreements, including preventative maintenance, spare parts supply, and software updates. Our customer support includes:

- Technical Assistance: Prompt support via phone, email, or video conferencing for troubleshooting.

- Remote Diagnostics: Capability to remotely access the machine's control system for rapid issue identification and resolution.

- On-site Service: A global network of skilled field engineers available for complex repairs or maintenance.

- Spare Parts: Guaranteed availability of genuine spare parts for the lifespan of the `carpet making equipment`.

- Training: Comprehensive training programs for your operators and maintenance teams.

Conclusion: The Future of Carpet Manufacturing is Intelligent and Efficient

The landscape of carpet manufacturing is undergoing a dynamic evolution, driven by technological advancements, increasing demands for precision, and an unyielding focus on sustainability. The modern carpet manufacturing machine, exemplified by advanced systems like the Automotive Carpet Production Line with Hot Air Penetration, stands at the vanguard of this transformation. These machines are far more than mere mechanical apparatuses; they are sophisticated integrated systems that embody engineering excellence, leveraging cutting-edge materials, precision manufacturing techniques, and intelligent control systems. Their capability to deliver uniform heating, rapid curing times, and unparalleled product consistency marks a significant departure from older carpet making equipment, offering substantial improvements in efficiency, quality, and material utilization. The inherent versatility of these machines allows for their application across diverse sectors, from the rigorous demands of the automotive industry to the specialized needs of commercial acoustics and beyond, producing high-value, durable, and aesthetically superior products.

The strategic decision to invest in a state-of-the-art carpet manufacturing machine transcends the initial capital outlay, the carpet manufacturing machine price, and represents a commitment to long-term operational excellence and market leadership. The tangible benefits, as demonstrated through real-world application cases, include drastically reduced waste, significant energy savings, enhanced product quality, and increased throughput. Furthermore, the emphasis on comprehensive after-sales support, robust warranties, and the provision of tailored, integrated solutions underscores the partnership approach of leading manufacturers. This holistic value proposition ensures that clients not only acquire cutting-edge technology but also gain a reliable ally committed to their continuous success and operational continuity. As industries worldwide pivot towards smart manufacturing and sustainable practices, the advanced carpet manufacturing machine is not just keeping pace; it is actively shaping the future of textile production, enabling new levels of innovation, efficiency, and environmental responsibility. Choosing the right carpet making equipment is thus a strategic imperative for any enterprise aiming to remain competitive and future-ready in the evolving global market.

References

- "Innovation Drives Automotive Textiles," Textile World, July 2023.

- "Advancements in Industrial Hot Air Heating Systems for Textile Processing," Journal of Textile Engineering & Technology, Vol. 45, Issue 3, 2021.

- "Future of Automotive Interiors: Materials and Manufacturing Processes," Automotive Manufacturing Solutions, May 2023.

- "Sustainable Manufacturing in the Textile Industry: Challenges and Opportunities," International Journal of Manufacturing Systems and Industrial Engineering, 2020.

- International Organization for Standardization (ISO) Official Website - ISO 9001 Quality Management.