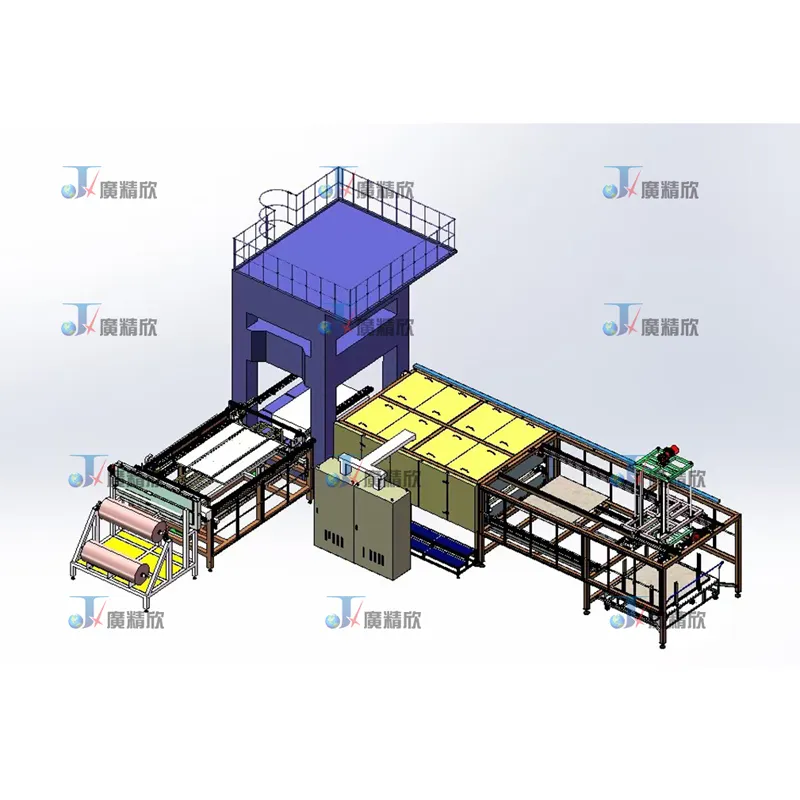

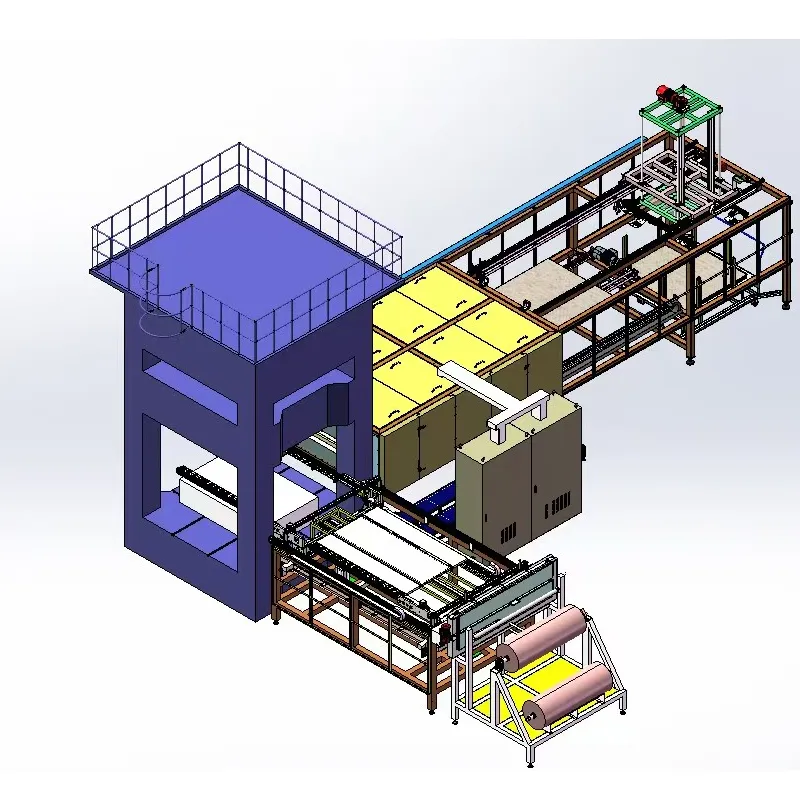

Precision Automotive Interior Sound Insulation Pad Oven

Precision Automotive Interior Sound Insulation Pad Oven

The Pivotal Role of Specialized Ovens in Automotive NVH Solutions

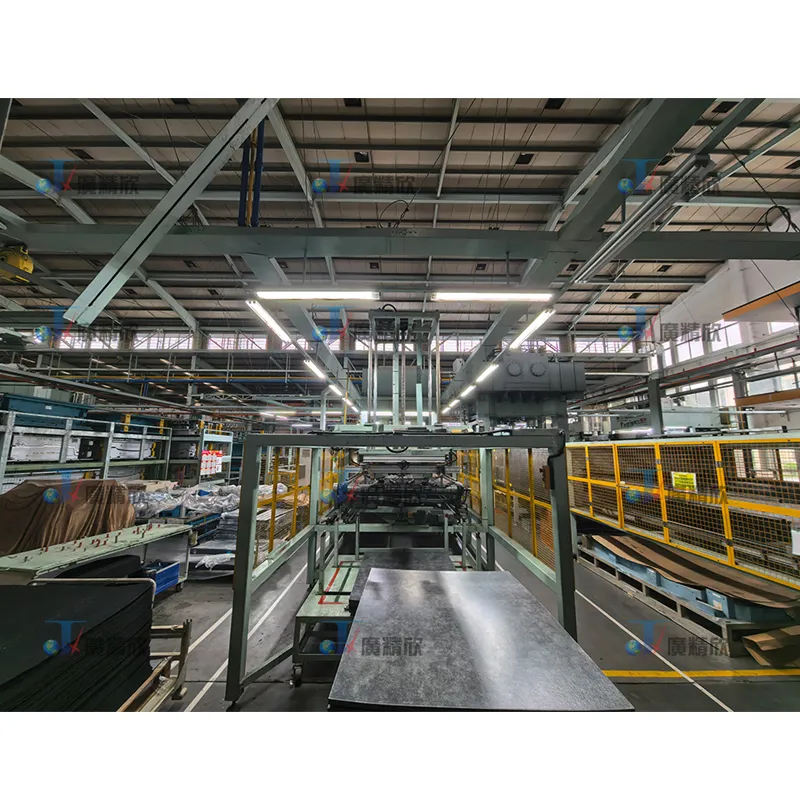

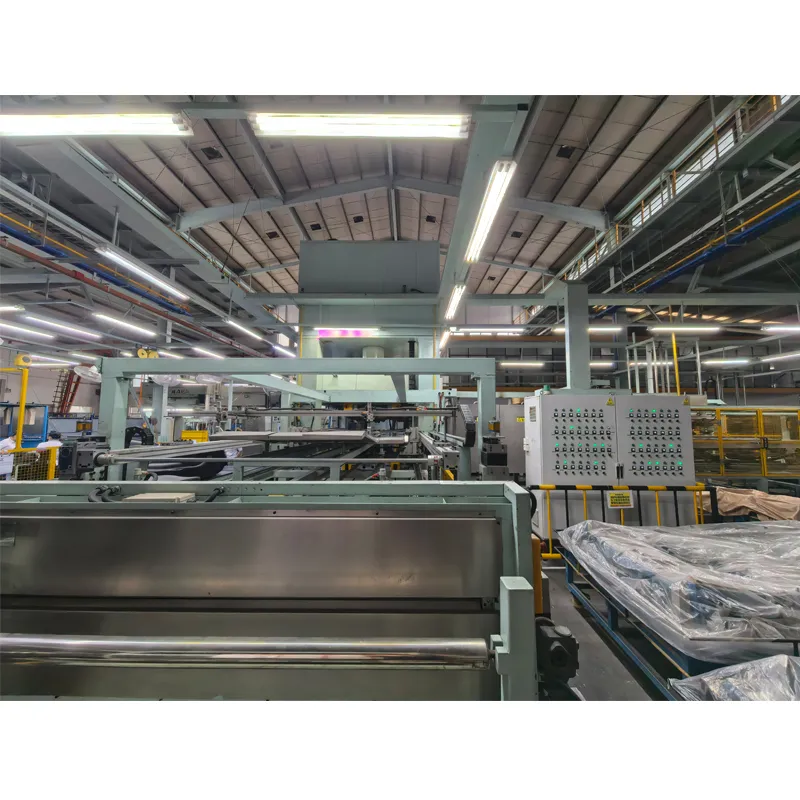

In the fiercely competitive automotive industry, the pursuit of superior comfort, safety, and acoustic performance drives continuous innovation. A critical component in achieving these goals is the effective management of Noise, Vibration, and Harshness (NVH). Advanced NVH solutions rely heavily on high-performance sound insulation materials, and the precise manufacturing of these materials necessitates highly specialized equipment. Among these, the Automotive Interior Sound - Insulation Pad Oven stands out as an indispensable asset. This bespoke industrial oven is engineered to provide precise temperature control and uniform heat distribution, essential for the curing, thermoforming, and bonding processes of various sound insulation pads used in vehicle interiors. Its sophisticated design ensures the structural integrity and acoustic efficacy of materials ranging from felt and foam composites to multi-layered damping sheets. The integration of such an oven into automotive production lines signifies a commitment to excellence in vehicle cabin refinement, directly contributing to enhanced occupant comfort and a premium driving experience. This dedication to acoustic optimization is not merely about luxury; it significantly impacts vehicle safety by reducing driver fatigue and allowing clearer communication within the cabin, reinforcing its position as a foundational technology for modern automotive manufacturing.

Industry Trends and Evolving Demands for NVH Solutions

The automotive industry is undergoing transformative shifts, largely driven by the electrification of vehicles and the growing consumer demand for quieter, more refined interiors. Electric Vehicles (EVs) inherently lack the combustion engine noise that traditionally masked other sounds, bringing new NVH challenges to the forefront. This mandates even more effective and lighter sound insulation solutions. Concurrently, the push for lightweighting vehicles to improve fuel efficiency and extend EV range necessitates innovative materials and processing techniques. The role of the Automotive Interior Sound - Insulation Pad Oven becomes even more critical in this evolving landscape, as it must accommodate the processing of new, advanced composite materials that are both lightweight and highly effective at absorbing or blocking sound. Trends indicate a move towards multi-material designs, including recycled content and sustainable polymers, requiring ovens capable of precise temperature profiles for complex curing cycles. Furthermore, the automation and digitalization of manufacturing lines demand ovens with advanced Human-Machine Interface (HMI) systems, seamless integration with plant-wide control systems (MES/SCADA), and predictive maintenance capabilities. Manufacturers are increasingly seeking ovens that offer not only superior thermal performance but also high throughput, energy efficiency, and adaptability to varied production scales, underscoring the shift towards smart manufacturing in the automotive sector.

Core Technology and Manufacturing Process Unveiled

Oven Construction and Material Superiority

The robust construction of an Automotive Interior Sound - Insulation Pad Oven is paramount to its long-term performance and the quality of the sound insulation pads it produces. Typically, the oven chamber is constructed from high-grade steel, such as SUS304 or equivalent, ensuring excellent corrosion resistance and thermal stability under continuous operation at elevated temperatures. The structural framework often utilizes precision-fabricated mild steel sections, designed for exceptional rigidity and minimal thermal distortion, preventing deformation over its extensive service life. Manufacturing processes for these critical components involve advanced techniques like CNC laser cutting for precise panel dimensions, automated welding for strong, uniform seams, and precision machining for critical interfaces and moving parts. Insulation material within the oven walls usually comprises high-density mineral wool or ceramic fiber blankets, meticulously layered to minimize heat loss and ensure energy efficiency. This multi-layered insulation strategy maintains consistent internal temperatures while keeping external surfaces safe for operators and reducing thermal stress on surrounding equipment.

Advanced Heating and Control Mechanisms

The operational heart of the Automotive Interior Sound - Insulation Pad Oven lies in its sophisticated heating and control systems. Heating methods vary, but forced convection ovens are common, utilizing powerful circulation fans to ensure uniform temperature distribution throughout the chamber, critical for consistent curing or thermoforming of complex insulation pads. Electric heating elements or gas burners (for larger systems) provide the primary heat source. Temperature accuracy is maintained via multiple RTD (Resistance Temperature Detector) sensors strategically placed within the oven, feeding data to a high-precision PID (Proportional-Integral-Derivative) control system. This closed-loop control minimizes temperature fluctuations, often within ±2°C or better, ensuring optimal material processing. For instance, composite insulation pads require precise temperature ramps and dwell times to activate binders and achieve desired acoustic properties without material degradation. The oven's PLC (Programmable Logic Controller) orchestrates the entire process, managing temperature profiles, conveyor speeds, and interlocks with other machinery on the production line. Safety mechanisms, including over-temperature protection, emergency stops, and interlocks on access doors, are integrated as standard to comply with stringent industrial safety regulations.

Quality Assurance and Applicable Standards

To ensure unparalleled quality and reliability, the manufacturing of an Automotive Interior Sound - Insulation Pad Oven adheres to rigorous international standards. Key certifications typically include ISO 9001 for quality management systems, guaranteeing consistent product quality throughout the design, manufacturing, and testing phases. Electrical components and safety features often conform to CE standards for European markets, and potentially UL or CSA for North America, ensuring compliance with local electrical and safety codes. Dimensional accuracy of manufactured parts is verified using CMM (Coordinate Measuring Machine) equipment, and welds undergo non-destructive testing (NDT) such as ultrasonic testing or dye penetrant inspection. Before shipment, each oven undergoes comprehensive Factory Acceptance Testing (FAT), simulating real-world operating conditions to validate performance parameters such as temperature uniformity, ramp rates, and control accuracy. This exhaustive testing ensures that the oven delivers its specified performance from day one. The typical service life of such a professionally manufactured oven can exceed 15-20 years with proper maintenance, showcasing its robust design and high-quality components, proving a valuable long-term investment for automotive manufacturers focused on efficiency and durability.

Technical Specifications and Performance Metrics

The performance of an Automotive Interior Sound - Insulation Pad Oven is defined by a range of critical technical parameters that directly impact its efficiency, material quality, and operational cost. These specifications are vital for automotive manufacturers and Tier 1 suppliers when evaluating and integrating such equipment into their production lines. Understanding these metrics ensures that the oven meets specific production volumes, material requirements, and energy consumption targets. The precise control over temperature profiles, conveyor speed, and air circulation makes these ovens highly versatile for various types of insulation pads, including those made from jute, felt, foam, and advanced composite materials, each with unique thermal processing needs. The design must accommodate diverse pad geometries and thicknesses while maintaining temperature uniformity across the entire product surface. This uniformity is crucial to prevent material degradation or uneven curing, which could compromise the acoustic performance and durability of the finished insulation pads.

Application Scenarios and Strategic Advantages

The versatility of the Automotive Interior Sound - Insulation Pad Oven allows its deployment across numerous critical stages of automotive component manufacturing, particularly within the NVH sector. Its primary applications include the thermoforming of pre-cut acoustic materials, the curing of binding agents in multi-layered sound deadening composites, and the pre-heating of materials before pressing or molding. For instance, in the production of lightweight dashboard insulators, the oven precisely heats a blend of fibers and thermoplastic binders, preparing it for subsequent compression molding into complex shapes that perfectly fit the vehicle's interior contours. Another key application is the production of wheel arch liners or floor pan insulators, where materials like felt or rubberized bitumen are processed to enhance their acoustic absorption and vibration damping properties. The precise temperature control of the oven ensures optimal material flow and bonding without compromising the material's inherent sound-dampening capabilities, which is crucial for achieving high-quality acoustic performance in the final vehicle.

Key Advantages in Automotive Production

The advantages derived from integrating a specialized Automotive Interior Sound - Insulation Pad Oven into a production line are multifaceted. Foremost is the significant improvement in the quality and consistency of sound insulation pads. Uniform heating prevents material degradation, ensuring that the acoustic properties, such as Noise Reduction Coefficient (NRC) and Sound Transmission Loss (STL), are consistently met. This translates directly to enhanced vehicle cabin quietness and comfort, a significant differentiator in today’s market. Secondly, these ovens contribute substantially to energy efficiency. Optimized insulation, precise temperature control, and efficient air circulation systems minimize heat loss and energy consumption, leading to lower operational costs and a reduced environmental footprint—a vital consideration for sustainability-focused manufacturers. Furthermore, the robust construction and long service life of these ovens reduce downtime and maintenance requirements, ensuring high production uptime and overall operational reliability. Their adaptability to various material types and production volumes makes them a highly flexible asset for dynamic automotive manufacturing environments, providing a competitive edge through superior product quality and cost-effective production.

Customization and Integrated Solutions for Unique Demands

In the highly specialized realm of automotive manufacturing, off-the-shelf solutions often fall short of meeting the unique demands of specific production lines, material specifications, or facility constraints. This is particularly true for an Automotive Interior Sound - Insulation Pad Oven, where optimal performance hinges on its seamless integration into an existing or planned production ecosystem. Leading manufacturers offer extensive customization options, collaborating closely with clients to design ovens that precisely align with their operational requirements. This includes variations in chamber dimensions, allowing for processing of unusually large or small insulation pads, or adapting to specific conveyor systems. Heating configurations can be tailored, such as multi-zone heating for intricate temperature profiles, or specific ventilation systems for handling volatile organic compounds (VOCs) released during curing of certain materials. Customization also extends to automation levels, from semi-automatic loading/unloading systems to fully integrated robotic material handling, enhancing throughput and reducing labor costs. Data connectivity features, such as OPC UA or Ethernet/IP, can be integrated to allow real-time monitoring and control from a central manufacturing execution system (MES), optimizing overall plant efficiency and providing valuable production data for continuous improvement initiatives.

Seamless Integration and Future-Proofing

Beyond bespoke physical design, comprehensive integration solutions are crucial. A custom-built Automotive Interior Sound - Insulation Pad Oven can be designed to interface directly with upstream material feeding systems and downstream pressing, trimming, or cooling stations. This end-to-end process optimization ensures a streamlined workflow, minimizing manual intervention and maximizing throughput. For instance, ovens can be equipped with specialized tooling interfaces to work with specific mold designs, ensuring perfect alignment and efficient heat transfer during thermoforming. Furthermore, considering the rapid evolution of automotive materials and manufacturing processes, the ability to upgrade or reconfigure the oven in the future is a significant advantage. Manufacturers committed to long-term partnerships provide modular designs and scalable control systems, allowing for future expansion or adaptation to new material types and processing requirements without necessitating a complete oven replacement. This foresight ensures that the investment in an advanced insulation pad oven remains viable and productive for decades, underpinning the long-term success of automotive interior sound solution providers.

Strategic Manufacturer Comparison and Selection Criteria

Selecting the right manufacturer for an Automotive Interior Sound - Insulation Pad Oven is a strategic decision that profoundly impacts production efficiency, product quality, and long-term operational costs. While specific company names are not discussed here, understanding the critical criteria for evaluating potential suppliers is paramount. A reputable manufacturer distinguishes itself through a proven track record of delivering high-performance industrial ovens, particularly within the automotive sector. This includes a robust R&D department capable of innovating and adapting to new material science and processing demands. Their expertise should be evident in the precision of their temperature control systems, the uniformity of heat distribution, and the energy efficiency of their designs. Look for manufacturers who prioritize robust construction using premium-grade materials and employ advanced fabrication techniques such as robotic welding and precision CNC machining, which are indicative of a durable, reliable product with a long service life. Furthermore, adherence to international quality standards such as ISO 9001 and relevant safety certifications (e.g., CE, UL) is non-negotiable, ensuring compliance and peace of mind.

Beyond Technical Specifications: Support and Partnership

Beyond the intrinsic technical specifications of an Automotive Interior Sound - Insulation Pad Oven, the quality of after-sales support and the manufacturer's commitment to a long-term partnership are equally vital. A top-tier supplier offers comprehensive engineering support from the initial consultation and design phase through to installation, commissioning, and operator training. Their capacity for providing swift and effective technical assistance, spare parts availability, and preventative maintenance programs is crucial for maximizing uptime and minimizing production interruptions. Manufacturers with a global service network can provide rapid response times, regardless of the client's geographical location. Furthermore, assess their flexibility in providing customized solutions that integrate seamlessly with existing or planned production lines, demonstrating their understanding of specific client needs rather than offering a one-size-fits-all approach. Choosing a partner with a deep understanding of automotive NVH requirements and a commitment to continuous improvement ensures not only the acquisition of a superior oven but also a collaborative relationship that drives sustained operational excellence and innovation in sound insulation pad production.

Real-World Impact: An Application Case Study Example

Consider a leading Tier 1 automotive supplier specializing in acoustic and thermal management components. Facing increased demands for lighter, more complex multi-layered sound insulation pads for next-generation EV platforms, their existing convection ovens struggled to maintain the required temperature uniformity across the larger, intricate pad designs, leading to inconsistent material properties and increased scrap rates. The challenge was to achieve precise curing of a new composite material combining recycled textile fibers with a low-melt thermoplastic binder, demanding a temperature uniformity of ±2°C across a 3-meter wide conveyor. To address this, the supplier invested in a custom-engineered Automotive Interior Sound - Insulation Pad Oven featuring advanced multi-zone PID control, high-volume forced air circulation, and a precision-engineered mesh belt conveyor system. The oven was equipped with an integrated cooling section to rapidly stabilize the material after curing, preventing post-processing warpage and further enhancing material consistency.

Transformative Results and Operational Excellence

The deployment of this new Automotive Interior Sound - Insulation Pad Oven led to remarkable improvements. Material scrap rates for the new composite pads plummeted by 18%, directly reducing waste and raw material costs. The consistency of the cured pads, as measured by density, thickness, and acoustic absorption coefficients (tested using ISO 10534-2: impedance tube method), significantly improved, consistently meeting stringent OEM specifications. This reliability allowed the supplier to secure new contracts for high-volume EV programs. Furthermore, the oven's optimized energy recovery system and superior insulation resulted in a 25% reduction in energy consumption compared to their previous ovens for the same throughput, directly contributing to their sustainability goals and reducing operational expenditures. The integrated PLC and HMI also provided comprehensive data logging and real-time process monitoring, enabling predictive maintenance and further optimizing production schedules. This case exemplifies how a purpose-built, technologically advanced oven can be a cornerstone in achieving manufacturing excellence and meeting the evolving demands of the automotive industry.

Commitment to Trust: FAQs, Delivery, and Warranty

Frequently Asked Questions (FAQ)

-

Q: What types of sound insulation materials can be processed by your Automotive Interior Sound - Insulation Pad Oven?

A: Our ovens are versatile and can process a wide range of materials, including natural fibers (e.g., jute, cotton shoddy), synthetic felts, foams (PU, PE, EVA), multi-layered composites with various binders, and bituminous damping sheets. Custom configurations can accommodate specific material requirements, ensuring optimal thermal processing for diverse acoustic applications. -

Q: How do you ensure temperature uniformity within the oven?

A: We employ a multi-pronged approach: high-volume forced air circulation using strategically placed fans and baffles, multiple precision RTD sensors feeding data to advanced PID controllers, and robust chamber insulation. This design ensures variations typically within ±2°C to ±5°C across the working zone, critical for consistent material processing. -

Q: What are the typical delivery and installation timelines?

A: Delivery times for a standard Automotive Interior Sound - Insulation Pad Oven typically range from 12 to 20 weeks, depending on customization levels and current production schedules. Installation and commissioning usually take an additional 1-3 weeks, facilitated by our experienced technical team. A detailed project timeline is provided upon order confirmation. -

Q: What kind of after-sales support and warranty do you offer?

A: We provide comprehensive after-sales support, including remote diagnostics, on-site technical assistance, and a readily available inventory of spare parts. Our standard warranty for the Automotive Interior Sound - Insulation Pad Oven covers 12 to 24 months from the date of commissioning or 18 to 30 months from shipment, covering manufacturing defects and component failures under normal operating conditions. Extended warranty options and preventative maintenance contracts are also available to ensure long-term reliability.

Commitment to Reliability and Support

Our dedication to client success extends far beyond the sale of an Automotive Interior Sound - Insulation Pad Oven. We understand that reliability, timely support, and transparent communication are paramount in the B2B sector. Our commitment to quality is underscored by our adherence to stringent manufacturing standards and rigorous factory acceptance testing (FAT) for every oven. We ensure that our equipment not only meets but often exceeds industry benchmarks for performance and safety. Furthermore, our global network of service engineers provides rapid response times for any technical queries or support requirements, minimizing potential downtime and maximizing your return on investment. We also offer comprehensive training programs for your operational and maintenance personnel, empowering your team to fully leverage the capabilities of our advanced oven systems, ensuring sustained optimal performance and prolonged operational life. This holistic approach ensures a trusting, productive partnership from initial consultation through the entire lifecycle of your oven.

Conclusion: Driving Automotive Acoustic Excellence

The continuous evolution of the automotive industry, particularly the accelerated shift towards Electric Vehicles and enhanced passenger experience, places unprecedented demands on NVH management. At the heart of meeting these demands is the sophisticated manufacturing of interior sound insulation pads, a process critically reliant on specialized thermal processing equipment. The Automotive Interior Sound - Insulation Pad Oven stands as a testament to engineering precision, offering the vital capability to process advanced materials with unparalleled consistency and efficiency. Its integrated design, precise temperature control, and robust construction are not just features but fundamental enablers of superior vehicle acoustics, contributing significantly to driver and passenger comfort, safety, and overall brand perception. Investing in a high-quality, customized oven represents a strategic decision for automotive manufacturers and Tier 1 suppliers aiming to optimize their production processes, reduce operational costs through energy efficiency, and consistently deliver world-class NVH solutions. As vehicles become quieter and more refined, the role of this advanced oven will only grow in importance, solidifying its position as a cornerstone technology for future automotive interior excellence.

References and Further Reading

- Journal of Sound and Vibration - Advancements in Acoustic Materials for Automotive Applications.

- SAE International - Technical Papers on Noise, Vibration, and Harshness (NVH) in Automotive Engineering.

- Polymer Engineering & Science - Studies on Thermoforming and Curing of Polymer Composites for Automotive Industry.

- International Journal of Thermal Sciences - Heat Transfer and Energy Efficiency in Industrial Ovens.

- Materials & Design - Lightweighting Strategies and Multi-Material Systems in Automotive Structures.