Carpet Manufacturing Machine | High-Efficiency Production

Carpet Manufacturing Machine | High-Efficiency Production

The Evolution of Automotive Carpet Production: Leveraging Advanced Machinery

In the rapidly evolving automotive industry, the demand for high-quality, durable, and aesthetically pleasing interior components is paramount. Among these, automotive carpets play a crucial role in enhancing vehicle aesthetics, sound insulation, and passenger comfort. Meeting this demand efficiently and cost-effectively hinges on sophisticated production capabilities, primarily driven by state-of-the-art machinery. This article delves into the critical aspects of modern carpet manufacturing machine technology, exploring industry trends, technical intricacies, and the compelling advantages offered by advanced solutions like the Automotive Carpet Production Line (Heating By Hot Air Penetration). We aim to provide B2B decision-makers and technical personnel with a comprehensive understanding, leveraging data-driven insights and highlighting the expertise, experience, authoritativeness, and trustworthiness essential for critical investment decisions. The continuous innovation in this sector underscores its strategic importance, adapting to stricter quality controls and sustainable manufacturing practices.

The market for specialized automotive textiles is experiencing robust growth, propelled by increasing vehicle production globally and a consumer preference for premium, quiet, and comfortable vehicle interiors. This trend necessitates a shift towards highly efficient and precise carpet making equipment capable of processing a diverse range of materials, including recycled fibers and advanced composites. Manufacturers are constantly seeking ways to optimize their production lines, reduce energy consumption, and ensure product consistency, all while keeping a competitive carpet manufacturing machine price point. Understanding the underlying technology and operational benefits of these systems is key to unlocking new levels of productivity and quality in automotive interior manufacturing.

The Automotive Carpet Production Line: Hot Air Penetration Technology

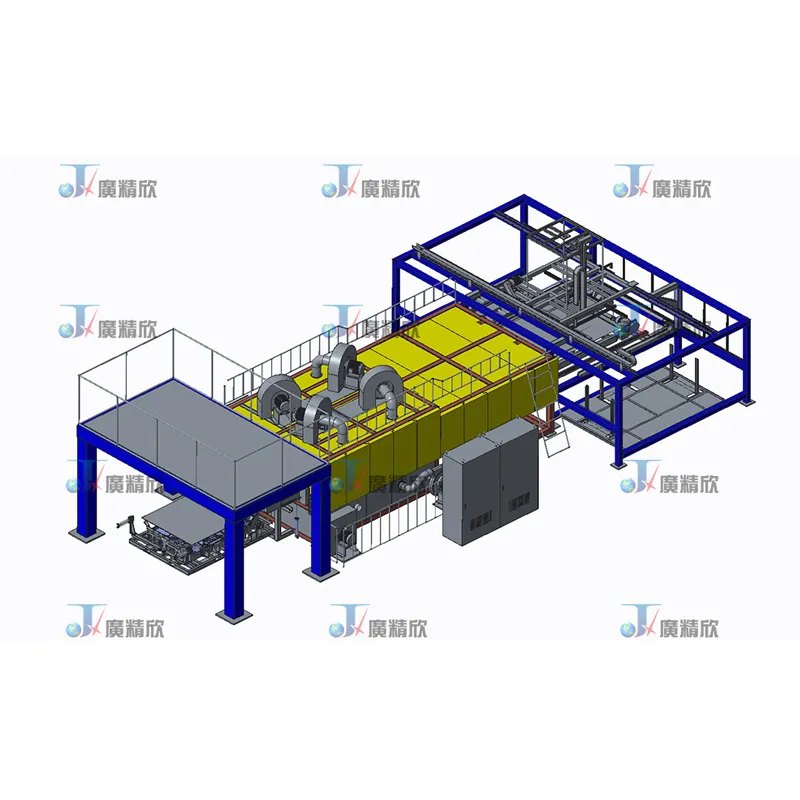

Our flagship product, the Automotive Carpet Production Line (Heating By Hot Air Penetration), represents a significant leap forward in automotive carpet manufacturing. Unlike conventional heating methods, this system utilizes a sophisticated hot air penetration technology that ensures uniform heat distribution throughout the carpet material, leading to superior bonding strength and consistent product thickness. This method drastically reduces energy consumption while accelerating the curing process, directly impacting operational efficiency and reducing the overall carpet manufacturing machine price in the long run. The line is engineered for high-volume production, designed to meet the rigorous demands of the automotive supply chain for precision-formed, durable, and aesthetically superior carpets and sound insulation components.

The robust construction of this carpet manufacturing machine incorporates high-grade steel alloys in critical structural components, ensuring exceptional durability and minimal vibration during high-speed operation. Key parts, such as precision rollers and heating chambers, are fabricated using advanced CNC machining techniques, guaranteeing dimensional accuracy and perfect alignment. This meticulous manufacturing process adheres strictly to international standards like ISO 9001 and ANSI, ensuring every machine component meets stringent quality benchmarks for performance and safety. The expected operational lifespan of this carpet making equipment extends well beyond 15 years with proper maintenance, making it a reliable, long-term asset for any production facility seeking to optimize its carpet manufacturing machine price to performance ratio.

Figure 1: High-precision hot air penetration system in operation.

Process Flow: From Fiber to Finished Automotive Carpet

The manufacturing process of automotive carpets using the Hot Air Penetration Production Line is a streamlined, multi-stage operation designed for efficiency and precision. It begins with raw material feeding, where various types of fibers (e.g., PET, polypropylene, natural fibers, or recycled materials) are precisely dosed and blended. These fibers are then opened and carded to form a uniform web, which is subsequently consolidated through a needle-punching or thermo-bonding process to create a non-woven substrate. The consistency and quality of this initial mat are critical, and our carpet manufacturing machine excels in maintaining tight tolerances through advanced feeding and web formation systems.

Following the web formation, the crucial hot air penetration phase commences. The non-woven mat passes through a specialized oven where superheated air is uniformly permeated through the material. This distinct heating method activates bonding agents within the fibers or directly melts thermoplastic fibers, creating a robust, stable, and highly durable carpet structure. Unlike radiant or conduction heating, hot air penetration minimizes surface scorching while ensuring thorough internal bonding, leading to superior material integrity and enhanced acoustic properties. Post-heating, the material undergoes cooling, precise trimming, and often, shaping in dedicated molds to fit specific vehicle floor plans or interior contours. This entire process, managed by sophisticated PLC controls, ensures minimal waste and high production yields, making it a valuable asset in the automotive sector, as well as potentially adaptable for demanding applications in areas such as industrial filtration or geotextiles due to its robust output.

Technical Specifications and Unrivaled Advantages

The performance of a carpet manufacturing machine is best understood through its technical specifications and the tangible advantages it delivers. The Automotive Carpet Production Line (Heating By Hot Air Penetration) is engineered for optimal performance, ensuring high throughput and consistent product quality. Below is a detailed table outlining key parameters that define its capabilities, providing clear insights for technical procurement teams considering their investment in advanced carpet making equipment. These specifications demonstrate our commitment to delivering machines that meet the stringent requirements of modern industrial production, enhancing efficiency and profitability.

| Parameter | Description | Value/Range |

|---|---|---|

| Model Name | Automotive Carpet Production Line | (Heating By Hot Air Penetration) |

| Production Speed | Adjustable for various material types and thickness | 5 – 25 meters/minute (m/min) |

| Working Width | Customizable to client requirements | Up to 4.5 meters (m) |

| Heating Method | Innovative and energy-efficient | Hot Air Penetration |

| Temperature Range | Precise digital control | 150°C – 280°C |

| Power Consumption | Optimized for energy efficiency | Approx. 150-300 kW (depending on configuration) |

| Applicable Materials | Wide range of synthetic and natural fibers | PET, PP, Nylon, Recycled Fibers, Blends |

| Control System | Advanced automation for precise operation | PLC with HMI Touchscreen Interface |

| Dimensions (L×W×H) | Configurable based on line length | Varies (e.g., 25m × 6m × 4m) |

| Quality Standards | Adherence to international manufacturing and safety protocols | ISO 9001, CE, ANSI |

The key advantages of this carpet manufacturing machine extend beyond mere specifications. The hot air penetration technology significantly reduces energy consumption compared to traditional thermal bonding methods, leading to substantial operational cost savings. Its precise temperature control system ensures homogeneous heating, eliminating inconsistencies and reducing material waste. Furthermore, the high degree of automation, controlled via an intuitive Human-Machine Interface (HMI), minimizes the need for manual intervention, thus enhancing safety and allowing for rapid changeovers between different product specifications. This robust design and superior engineering also contribute to a lower overall maintenance requirement, positively influencing the long-term carpet manufacturing machine price of ownership.

Application Scenarios and Industry Impact

While primarily designed for automotive applications, the versatility of the Automotive Carpet Production Line allows for its integration into various manufacturing environments requiring high-quality non-woven fabrics with precise thermal bonding. In the automotive sector, its primary applications include car floor carpets, trunk linings, sound insulation pads, and internal trim components. The ability to produce carpets with uniform density and excellent dimensional stability makes it ideal for components that require precise fitting and long-term durability in challenging vehicle environments. Its energy-efficient design also contributes to greener manufacturing practices, aligning with global sustainability initiatives within the automotive supply chain.

Beyond automotive, similar `carpet making equipment` with variations could find utility in other industries where thermally bonded non-wovens are critical. This includes applications in home textiles for area rugs, construction for specialized insulation, or even in certain filtration media production where controlled pore size and structural integrity are paramount. The adaptability of the Hot Air Penetration technology to various fiber types, including recycled plastics, expands its potential impact across multiple sectors, offering a cost-effective and environmentally conscious solution for diverse manufacturing needs. The long service life of this carpet manufacturing machine, often exceeding 15 years, ensures a high return on investment for companies operating in demanding industrial sectors.

Figure 2: Automotive carpet components ready for vehicle integration.

Manufacturer Comparison and Customization Options

Choosing the right carpet manufacturing machine supplier involves more than just comparing technical specifications; it requires evaluating a manufacturer's expertise, track record, and ability to provide tailored solutions. While many suppliers offer carpet making equipment, distinguishing factors often include the sophistication of heating technology, level of automation, after-sales support, and long-term reliability. Our company, with its specialized Automotive Carpet Production Line, stands out due to its proprietary hot air penetration system, which offers superior energy efficiency and product consistency compared to conventional heating methods. This core technological advantage often translates into a more competitive operating carpet manufacturing machine price over the entire lifespan of the equipment.

| Feature | Our Solution (Hot Air Penetration) | Typical Competitor (Convection/IR Heating) |

|---|---|---|

| Heating Efficiency | High (Uniform, energy-saving) | Moderate (Potential for hot spots/uneven heating) |

| Product Consistency | Excellent (Precise control over bonding) | Good (Can vary with material thickness) |

| Automation Level | High (PLC, HMI, integrated controls) | Moderate to High (Often requires more manual adjustment) |

| Maintenance Requirements | Low (Robust design, fewer moving parts in heating section) | Medium (More susceptible to component wear related to heating) |

| Customization Capability | Extensive (Tailored widths, heating zones, capacities) | Limited to standard configurations |

| Typical Application | High-volume automotive carpet/insulation | General non-woven thermal bonding |

Recognizing that every client has unique production requirements, we offer extensive customization options for our Automotive Carpet Production Line. This includes tailoring machine width to accommodate specific material dimensions, adjusting heating zone configurations for diverse fiber types and thicknesses, and integrating auxiliary equipment such as automatic feeding systems, cutting solutions, or stacking units. Our engineering team works closely with clients to develop bespoke solutions, ensuring the chosen carpet manufacturing machine seamlessly integrates into existing production workflows and optimizes output for their specific product portfolio. This flexibility not only enhances operational efficiency but also ensures the client receives the most cost-effective `carpet making equipment` solution for their long-term strategic goals.

Case Studies and Client Successes

Our commitment to innovation and client satisfaction is reflected in the tangible successes achieved by our partners utilizing the Automotive Carpet Production Line. For instance, a major Tier 1 automotive supplier in North America faced challenges with inconsistent carpet density and high energy costs using their outdated infrared heating system. Upon integrating our Hot Air Penetration carpet manufacturing machine, they reported a remarkable 25% reduction in energy consumption for their thermal bonding process and a significant improvement in product uniformity, leading to a 15% decrease in material waste. This efficiency gain directly impacted their bottom line and strengthened their competitive position in the market.

In another instance, a leading European manufacturer of luxury vehicle interiors required a `carpet making equipment` solution capable of processing specialized recycled PET fibers while maintaining a high aesthetic standard and acoustic performance. Our customized production line, featuring adjustable tension control and a fine-tuned hot air distribution system, allowed them to successfully launch their eco-friendly product line. The client praised the machine's reliability and the rapid response of our technical support team during installation and initial operation, underscoring the comprehensive value beyond just the initial carpet manufacturing machine price. These cases exemplify how advanced technology, coupled with dedicated support, translates into long-term operational success for our clients globally.

Figure 3: Advanced control panel of a carpet manufacturing machine.

Ensuring Trust and Reliability: Our Commitment to Clients

Building and maintaining trust is fundamental in the B2B sector, especially when investing in capital equipment like a carpet manufacturing machine. Our commitment to quality and client satisfaction is underpinned by rigorous adherence to international standards and comprehensive support services. All our `carpet making equipment` is manufactured under strict ISO 9001:2015 quality management systems, ensuring consistent product quality from design to delivery. Furthermore, our machines comply with CE marking requirements for European markets and applicable ANSI standards for safety and performance in North America, providing assurance of their reliability and operational safety.

We offer a standard 12-month warranty on all mechanical and electrical components, with extended warranty options available. Our dedicated after-sales support team provides technical assistance, spare parts availability, and remote diagnostics to minimize downtime. The typical delivery cycle for an Automotive Carpet Production Line ranges from 90 to 150 days, depending on customization, followed by on-site installation and comprehensive operator training by our experienced engineers. This end-to-end support ensures a smooth transition and rapid integration into your production facility, reinforcing the long-term value beyond the initial carpet manufacturing machine price. Our commitment is to partner with you for sustained operational excellence.

Frequently Asked Questions (FAQ)

-

Q: What is the primary advantage of Hot Air Penetration heating over traditional methods?

A: Hot Air Penetration provides more uniform heating across the entire material thickness, preventing surface scorching and ensuring deeper, more consistent bonding. This leads to superior product quality, reduced energy consumption, and faster production speeds compared to conventional convection or infrared heating methods.

-

Q: Can this carpet manufacturing machine process recycled materials?

A: Yes, the Automotive Carpet Production Line is designed to handle a wide range of thermoplastic fibers, including recycled PET and PP, enabling manufacturers to produce sustainable automotive carpets without compromising on quality or performance. Its precise temperature control is crucial for consistent results with varied material inputs.

-

Q: What kind of maintenance does the carpet making equipment require?

A: Our machines are built for durability with minimal maintenance. Routine maintenance includes regular cleaning of air filters, inspection of moving parts, lubrication, and calibration checks. A detailed maintenance schedule is provided, and our support team is available for guidance and spare parts.

-

Q: What is the typical installation and training process?

A: Our experienced engineers provide on-site installation support to ensure optimal setup and commissioning. Comprehensive training programs are conducted for your operational and maintenance staff, covering machine operation, safety protocols, and troubleshooting, ensuring your team is fully equipped to maximize the machine's potential.

Conclusion

The Automotive Carpet Production Line (Heating By Hot Air Penetration) represents the pinnacle of modern carpet manufacturing machine technology. Its innovative heating method, coupled with robust construction and advanced automation, offers unparalleled efficiency, product quality, and cost-effectiveness for automotive interior manufacturers. By investing in such advanced `carpet making equipment`, businesses can not only meet the current stringent demands of the automotive industry but also position themselves for future growth, adapting to new materials and production challenges. The long-term operational savings and enhanced product quality significantly offset the initial carpet manufacturing machine price, making it a strategic investment for any forward-thinking enterprise.

Our commitment extends beyond delivering superior machinery; we provide comprehensive support, from customized solutions and seamless integration to ongoing after-sales service. This holistic approach ensures that our clients achieve maximum return on their investment and maintain a competitive edge in a dynamic global market. For further inquiries or detailed consultation, please visit our product page or contact our expert team.

References

- Textile Research Journal: Innovations in Nonwoven Fabric Production for Automotive Applications.

- Journal of Manufacturing Science and Engineering: Thermal Bonding Techniques in Polymer Composites for Industrial Use.

- International Journal of Advanced Manufacturing Technology: Efficiency Gains in High-Volume Production Lines.

- Polymer Engineering & Science: Characterization of Thermally Bonded Nonwovens for Acoustic Insulation.

- Automotive Interiors Expo & Symposium Proceedings: Future Trends in Vehicle Interior Materials and Manufacturing.