Advanced Carpet Manufacturing Machines for Efficient Production

Advanced Carpet Manufacturing Machines for Efficient Production

Advancing Automotive Interiors: The Role of Modern Carpet Manufacturing Technologies

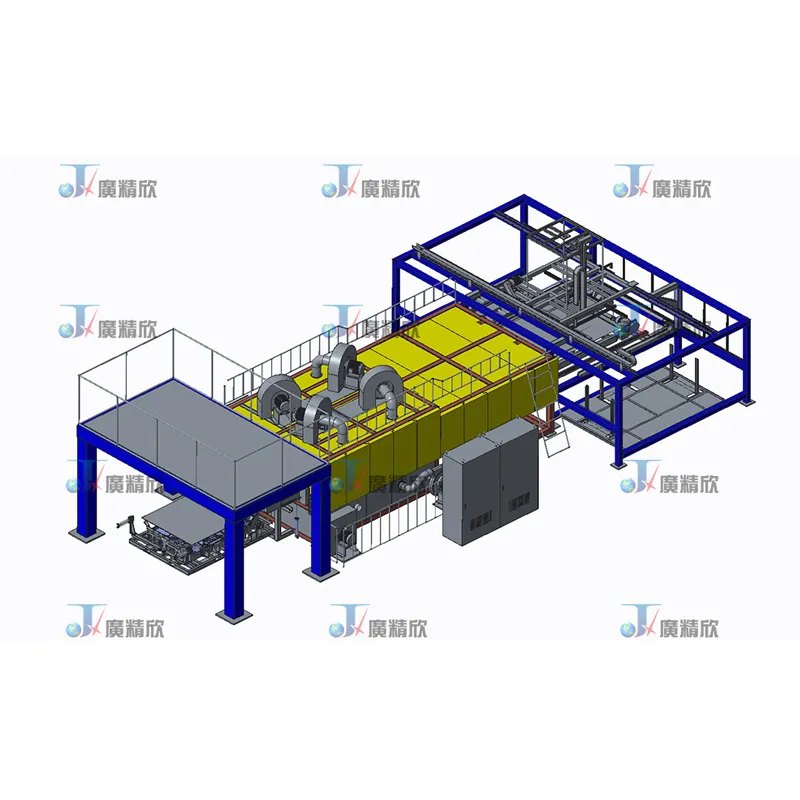

The global automotive industry is undergoing a transformative period, driven by evolving consumer demands for enhanced comfort, superior aesthetics, and sustainable manufacturing practices. Within this landscape, automotive interior components, particularly carpets, play a pivotal role in defining vehicle acoustics, insulation, and overall occupant experience. The demand for lightweight, durable, and aesthetically versatile automotive carpets necessitates sophisticated production methodologies and cutting-edge equipment. Modern carpet manufacturing machine solutions are at the forefront of this evolution, integrating advanced thermal bonding techniques and precision control systems to deliver high-performance products. Our Automotive Carpet Production Line, specifically designed with Hot Air Penetration heating, represents a significant leap forward in this domain, offering unparalleled efficiency, material adaptability, and consistent quality. This innovative approach addresses critical industry trends, including the increasing use of recycled materials, the imperative for energy reduction in manufacturing processes, and the need for flexible production lines capable of handling diverse product specifications and complex geometric designs common in contemporary vehicle interiors. The strategic adoption of such advanced equipment is not merely an operational upgrade but a fundamental shift towards a more competitive and sustainable future for automotive component suppliers worldwide.

The market for automotive carpets is experiencing robust growth, propelled by the increasing production of electric vehicles and the continuous innovation in interior design. As vehicle manufacturers strive to differentiate their offerings, the quality, performance, and environmental footprint of interior materials become increasingly critical. This necessitates investments in state-of-the-art carpet manufacturing machine technology that can deliver superior products while optimizing operational costs. Key trends include the development of multi-layered carpets for enhanced sound absorption, lightweight constructions to improve fuel efficiency and extend EV range, and the incorporation of sustainable and recyclable fibers. Furthermore, the integration of smart manufacturing principles, such as IoT connectivity and real-time data analytics, is transforming how these production lines operate, leading to predictive maintenance, optimized resource utilization, and reduced downtime. Our specialized production line is engineered to meet these rigorous demands, ensuring that manufacturers can produce automotive carpets that excel in durability, acoustic performance, and aesthetic appeal, all while adhering to the strictest industry standards. This holistic approach ensures that every aspect of the production process, from raw material handling to final product finishing, is meticulously controlled to achieve desired outcomes and support the long-term success of our clients in a rapidly evolving market landscape.

The Advanced Process: Hot Air Penetration in Automotive Carpet Production

The core innovation of our Automotive Carpet Production Line lies in its Hot Air Penetration heating system, a sophisticated thermal bonding method that ensures unparalleled quality and efficiency in non-woven automotive carpet manufacturing. Unlike traditional heating methods that rely on surface contact or radiant heat, hot air penetration involves forcing precisely heated air through the fibrous web. This convective heat transfer mechanism uniformly heats the entire material thickness, from the top surface to the bottom, ensuring that all thermoplastic fibers reach their optimal melting temperature for bonding. This process eliminates common issues such as uneven bonding, delamination, or brittle spots often seen with less precise heating techniques. The machine’s robust construction, utilizing high-grade steel components fabricated through advanced CNC machining and precision welding, ensures structural integrity and minimal vibration during operation, contributing to a longer lifespan and consistent performance. This meticulous approach to machine manufacturing guarantees the durability and reliability essential for continuous, high-volume production cycles in the demanding automotive sector, allowing for stable operation and reduced maintenance over its extensive operational life, typically exceeding 15 years with proper care and routine servicing, aligning with industry standards like ISO 9001 for quality management in equipment manufacturing.

This heating methodology offers several distinct technical advantages. Firstly, it provides exceptional energy efficiency, as the heated air directly transfers energy to the fibers, minimizing heat loss and reducing overall energy consumption compared to conventional heating systems. Secondly, the precise control over air temperature and velocity ensures that different fiber types, including recycled PET, polypropylene (PP), and blends, can be optimally processed without degradation, maintaining the material's structural integrity and performance characteristics such as sound absorption and wear resistance. This adaptability is crucial for manufacturers looking to diversify their product offerings and incorporate sustainable materials. Furthermore, the system’s design incorporates advanced air recirculation and filtration, optimizing heat recovery and maintaining a clean operating environment, which is vital for product purity and worker safety. The integration of high-precision sensors and a sophisticated PLC (Programmable Logic Controller) system allows for real-time monitoring and adjustment of temperature profiles, ensuring that each square meter of carpet meets stringent quality specifications and exhibits uniform density and thickness. This level of control is paramount for achieving the consistent, high-quality output demanded by automotive OEMs and for reducing material waste due to process variations.

Comprehensive Process Flow of Automotive Carpet Manufacturing

The production of automotive carpets using our specialized line involves a meticulously engineered multi-stage process, ensuring high-quality, consistent output suitable for demanding automotive applications. The journey begins with Fiber Preparation and Blending, where various synthetic fibers, such as polyester (PET) and polypropylene (PP), are fed into openers and blenders. This stage is critical for achieving the desired fiber mix, color uniformity, and opening the fiber bales into individual filaments. Next, the prepared fibers move to the Web Forming section, typically employing an air-laid or carding system, which precisely lays down the fibers onto a conveyor belt to form a uniform web. The density and thickness of this web are meticulously controlled at this stage, influencing the final carpet’s properties such as sound absorption and resilience. High-precision sensors and feedback loops, integrated with the PLC, ensure that web weight and consistency meet predefined specifications, minimizing material waste and guaranteeing product uniformity throughout the entire production run. This foundational step is critical for the subsequent thermal bonding process, as any inconsistencies here would propagate and compromise the final product's integrity.

Following web formation, the material enters the core of the system: the Hot Air Penetration Thermal Bonding Oven. Here, heated air is forced through the non-woven web, activating the thermoplastic binder fibers or melting the low-melt components within the fiber blend. The precise temperature control and uniform airflow ensure complete and consistent bonding across the entire width and depth of the material, which is paramount for the durability and structural integrity of the automotive carpet. Post-bonding, the bonded web undergoes Cooling, where it is rapidly cooled to stabilize the newly formed structure and prevent any deformation. This rapid cooling is essential for setting the fibers in their bonded state, ensuring dimensional stability. The carpet then proceeds to Calendering and Surface Treatment, where it may pass through heated rollers to achieve a specific thickness, surface smoothness, or texture. This stage can also incorporate anti-slip backings or other functional layers. Finally, the finished automotive carpet is subjected to Trimming and Winding, where it is cut to specified widths and wound onto rolls, ready for further processing such as molding into specific vehicle floor shapes or direct shipment. Throughout this entire process, adherence to rigorous inspection standards, including ISO 17025 for testing laboratories and specific automotive industry standards like ISO/TS 16949 (now IATF 16949) for quality management systems, ensures that every component of the carpet making equipment and the final product meets the highest benchmarks for performance and reliability in diverse and demanding applications like automotive interiors.

Technical Specifications and Performance Metrics

The Automotive Carpet Production Line (Heating By Hot Air Penetration) is engineered for high performance and reliability, offering a suite of technical specifications designed to meet the rigorous demands of automotive manufacturers. The core operational parameters include a typical production speed ranging from 5 to 30 meters per minute, adjustable based on material type and desired carpet thickness, which commonly ranges from 2mm to 15mm. The working width of the line is customizable, often between 2.5 and 4.5 meters, accommodating various vehicle model requirements. The hot air oven, a critical component, features multiple heating zones, each with independent temperature control, allowing for precise thermal profiles to be applied across the web. The maximum operating temperature can reach up to 250°C (482°F), with a temperature uniformity variance typically less than ±2°C across the web width, ensuring consistent bonding. The sophisticated PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) system provide intuitive control over all parameters, offering real-time data monitoring, fault diagnostics, and recipe management for different product specifications, enhancing operational efficiency and reducing human error. This advanced control system integrates seamlessly with factory automation protocols, providing comprehensive insights into production metrics and facilitating proactive adjustments to optimize throughput and quality.

Beyond these core specifications, the line's robust construction utilizes high-quality, corrosion-resistant stainless steel for critical components exposed to heat and air, ensuring durability and compliance with industrial safety standards (e.g., ANSI B11.19 for machine guarding). The total installed power typically ranges from 150 kW to 400 kW, depending on the line configuration and capacity, with optimized energy recovery systems minimizing consumption, aligning with the "energy saving" advantage. For example, specific lines have demonstrated up to 20% energy savings compared to radiant heating systems. The precision of the carpet manufacturing machine is further exemplified by its ability to maintain a web weight consistency of ±5% or better, which is vital for acoustic performance and material yield. The integrated tension control system ensures consistent web tension throughout the process, preventing material distortion or stretching. Furthermore, noise levels during operation are designed to be below 80 dB, meeting industrial safety regulations. The modular design of the entire production line allows for future upgrades or expansions, ensuring long-term applicability and return on investment for automotive textile producers. Below is a representative table of general parameters for a typical high-performance automotive carpet production line.

Typical Automotive Carpet Production Line Parameters

| Parameter | Description/Value Range |

|---|---|

| Heating Method | Hot Air Penetration (Convective) |

| Production Speed | 5 - 30 m/min (Adjustable) |

| Working Width | 2.5 - 4.5 meters (Customizable) |

| Carpet Thickness Range | 2 mm - 15 mm |

| Max. Operating Temperature | Up to 250°C |

| Temperature Uniformity | ±2°C across width |

| Control System | Siemens PLC with HMI Touchscreen |

| Installed Power | 150 - 400 kW (Config. Dependent) |

| Energy Efficiency | Up to 20% improved vs. radiant heating |

| Material Compatibility | PP, PET, Recycled Fibers, Blends |

| Web Weight Consistency | ±5% |

| Service Life | 15+ Years (with proper maintenance) |

Application Scenarios and Strategic Advantages

The Automotive Carpet Production Line (Heating By Hot Air Penetration) finds its primary application in the high-volume manufacturing of diverse automotive interior components. These include, but are not limited to, main floor carpets, trunk liners, wheel arch covers, and various acoustic insulation panels. The versatility of the line allows for the production of materials with varying densities and thicknesses, catering to different vehicle segments and acoustic requirements. For instance, thicker, denser carpets are crucial for premium vehicle cabins to enhance noise, vibration, and harshness (NVH) characteristics, while thinner, lightweight materials are essential for electric vehicles to maximize range efficiency. Beyond automotive, the underlying technology of this carpet manufacturing machine is adaptable to other non-woven thermal bonding applications requiring precise heat treatment, such as geotextiles, filtration media, and certain industrial composites, showcasing its broad applicability. The modular design enables seamless integration into existing factory layouts or the establishment of new, fully automated production facilities, providing a scalable solution for manufacturers aiming to expand their capacity or diversify their product lines in a cost-effective manner.

The strategic advantages of deploying this advanced carpet making equipment are multifaceted. Firstly, the "energy saving" aspect is paramount; the hot air penetration technology significantly reduces energy consumption compared to traditional methods, contributing to lower operating costs and a reduced carbon footprint, aligning with global sustainability initiatives. Secondly, its "anti-corrosion" properties, stemming from the use of high-grade materials and protective coatings in its construction, ensure a longer service life and minimal maintenance, even in challenging industrial environments. This robustness translates into higher uptime and a lower total cost of ownership over the equipment's lifespan. Thirdly, the "high efficiency" of the continuous production process, coupled with precise digital control, allows for rapid changeovers between different product specifications and minimizes material waste, maximizing throughput. Lastly, the consistent quality achievable with this line, particularly in terms of uniform bonding and dimensional stability, results in superior finished products that meet stringent OEM quality standards, thereby enhancing customer satisfaction and reinforcing brand reputation for automotive component suppliers. The ability to customize production parameters for different material blends and end-use requirements further solidifies its position as a leading solution for modern automotive textile manufacturing.

Manufacturer Comparison and Value Proposition

When evaluating carpet manufacturing machine price and capabilities, industrial buyers typically assess several critical factors beyond the initial investment. These include the level of automation, throughput capacity, R&D capabilities of the manufacturer, and the quality of after-sales support. While some manufacturers may offer seemingly lower upfront costs, they often compromise on advanced control systems, energy efficiency, or material compatibility, leading to higher operational expenses and limited product versatility in the long run. Our Automotive Carpet Production Line stands out by providing a superior balance of these critical attributes. We emphasize fully integrated automation, from automated fiber feeding to precise winding, minimizing manual intervention and maximizing consistent output. Our R&D continually focuses on incorporating the latest advancements in thermal bonding, material science, and automation, ensuring our clients benefit from state-of-the-art technology that keeps them competitive in a rapidly evolving market. This commitment to innovation is reflected in features like predictive maintenance sensors, which minimize unscheduled downtime by identifying potential issues before they escalate, thereby enhancing overall equipment effectiveness (OEE).

Our value proposition extends significantly beyond just the hardware. We offer comprehensive customized solutions, understanding that each client has unique production requirements and spatial constraints. Our engineering team collaborates closely with clients to design lines optimized for their specific product mix, production volume, and factory footprint. This includes tailoring features such as working width, oven length, and integration with existing upstream or downstream processes like needle punching or lamination. Furthermore, our commitment to customer success is underscored by robust after-sales support, encompassing installation, commissioning, operator training, and readily available spare parts. We provide extensive technical documentation, including detailed operational manuals and troubleshooting guides, ensuring smooth and efficient long-term operation. Our service team, backed by years of experience in textile machinery, is available for on-site support and remote diagnostics, ensuring minimal disruption to production. This holistic approach, combining advanced technology, customizable solutions, and unparalleled support, positions our carpet making equipment as a strategic investment rather than just a purchase, offering a superior return on investment (ROI) through enhanced efficiency, reduced operational costs, and the production of high-quality, market-leading automotive carpets that meet and exceed industry standards.

Ensuring Quality, Reliability, and Trustworthiness

At the heart of our operations lies an unwavering commitment to quality and reliability, underpinned by stringent adherence to international standards and rigorous internal protocols. Our manufacturing facilities are ISO 9001:2015 certified, signifying a robust quality management system that governs every stage from design and raw material sourcing to production, assembly, and final testing of each carpet manufacturing machine. Components are sourced exclusively from reputable global suppliers, and critical parts undergo meticulous inspection, often involving non-destructive testing (NDT) such as ultrasonic or magnetic particle inspection, to ensure structural integrity. Furthermore, specific automotive industry standards, such as those related to material flammability (e.g., FMVSS 302) or acoustic performance (e.g., ISO 354), are deeply integrated into the design considerations for the carpets produced by our line, ensuring that the output consistently meets the most demanding automotive OEM specifications. This comprehensive quality assurance framework not only ensures the durability and longevity of our equipment but also translates directly into the high-performance and consistent quality of the automotive carpets produced on our lines, building immense trust with our global clientele through proven performance and certified compliance.

Our trustworthiness is built on transparent processes and steadfast support. We provide clear, comprehensive documentation for every machine, including detailed specifications, operation manuals, maintenance schedules, and spare parts lists. Each production line undergoes extensive factory acceptance testing (FAT) before shipment, where customers are often invited to witness the machine's performance with their specific materials, ensuring it meets all agreed-upon parameters. Our standard warranty commitment is typically 12-24 months for major components, with extended service contracts available for peace of mind. The typical delivery cycle, from order confirmation to factory acceptance, ranges from 90 to 180 days, depending on customization complexity, with clear communication at every milestone. Post-installation, our dedicated customer support team provides comprehensive technical assistance, remote diagnostics, and on-site visits when required. We maintain a vast inventory of critical spare parts, ensuring rapid availability and minimizing potential downtime. This dedication to end-to-end support and a proactive problem-solving approach reinforces our reputation as a reliable partner in the automotive textile industry, fostering long-term relationships based on performance, trust, and mutual success.

Frequently Asked Questions (FAQ)

Our Hot Air Penetration line is highly versatile and capable of processing a wide range of thermoplastic fibers, including but not limited to polypropylene (PP), polyethylene terephthalate (PET), recycled PET (rPET) flakes or fibers, and various blends. This adaptability allows manufacturers to produce diverse automotive carpet products, from standard floor coverings to specialized acoustic insulation layers, while also supporting sustainable manufacturing initiatives by effectively utilizing recycled content. The precise temperature control of the hot air system ensures optimal bonding for each fiber type, preventing degradation and maintaining the material's structural integrity and performance characteristics, which is critical for meeting automotive industry specifications for durability, sound absorption, and aesthetic appeal. This flexibility allows our clients to respond quickly to market demands and material innovations.

Hot Air Penetration offers several key advantages over conventional heating methods like drum heaters or radiant ovens. Firstly, it ensures superior heat uniformity throughout the entire thickness of the non-woven web, leading to more consistent and stronger bonding without surface scorching or internal unbonded areas. Secondly, it is significantly more energy-efficient, as heated air directly penetrates the material, minimizing heat loss and reducing operational costs. Thirdly, it offers greater material compatibility and processing flexibility, allowing for finer control over the bonding process for various fiber types and thicknesses. This precision contributes to higher product quality, reduced material waste, and increased throughput compared to less controlled heating techniques, making it a preferred choice for high-performance automotive carpet production where consistent quality is paramount.

Our Automotive Carpet Production Line offers a high degree of automation, managed by an advanced PLC (Programmable Logic Controller) system and an intuitive HMI (Human-Machine Interface) touchscreen. This enables automated control over fiber feeding, web forming, oven temperature and speed, tension control, trimming, and winding. The automation significantly enhances efficiency by reducing the need for manual intervention, minimizing human error, and ensuring consistent production parameters around the clock. Real-time data monitoring and diagnostic capabilities allow for immediate identification and resolution of issues, minimizing downtime. Furthermore, recipe management functions enable quick changeovers between different product specifications, drastically improving production flexibility and overall line efficiency, which is crucial for meeting demanding production schedules in the automotive supply chain and optimizing the entire manufacturing process.

Conclusion and References

The Automotive Carpet Production Line (Heating By Hot Air Penetration) represents a pinnacle in modern non-woven textile manufacturing, specifically tailored for the intricate and demanding requirements of the automotive industry. Its advanced Hot Air Penetration technology ensures superior product quality through uniform thermal bonding, while its energy efficiency and robust construction contribute to lower operational costs and an extended service life. By integrating sophisticated automation, precise control systems, and modular design, this carpet manufacturing machine offers unparalleled versatility, allowing manufacturers to produce a diverse range of high-performance automotive carpets with consistent quality and minimal environmental impact. The strategic advantages, including significant energy savings, enhanced durability, and high throughput, position this equipment as a critical investment for automotive component suppliers aiming to maintain a competitive edge and respond effectively to evolving market trends for lightweight, sustainable, and aesthetically refined vehicle interiors.

Academic and Industry References:

- Textile Research Journal

- Journal of Industrial Textiles

- International Journal of Nonwovens

- SAE International Technical Papers (Society of Automotive Engineers)

- Journal of Cleaner Production