car mat making machine - Guangzhou Jingxin Electric Machinery Co., Ltd.|Compact Design&Energy-Efficient Heating

car mat making machine - Guangzhou Jingxin Electric Machinery Co., Ltd.|Compact Design&Energy-Efficient Heating

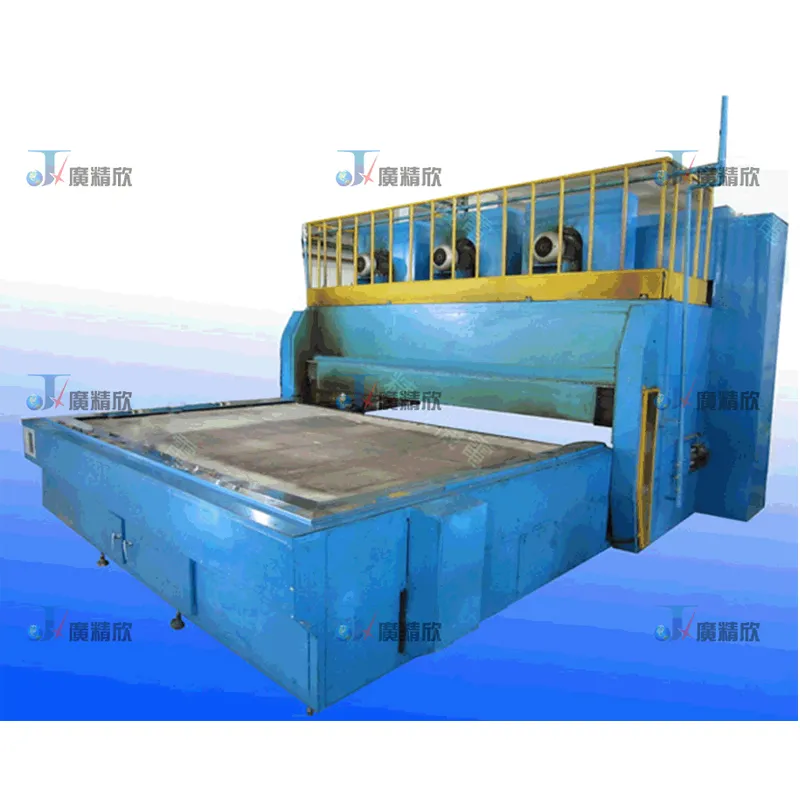

The Internal Circulating Air Electrically Heating Oven represents a cutting-edge solution for industries reliant on thermoplastic materials. Engineered for precision, efficiency, and adaptability, this oven is a cornerstone in modern manufacturing processes, particularly in the production of automotive carpets and other thermoplastic-coated products. This article delves into the product's core features, advantages, technical specifications, applications, and the company behind its innovation.

Product Overview and Core Features

The Internal Circulating Air Electrically Heating Oven is a specialized piece of equipment designed for the production of thermoplastic materials. It integrates advanced heating technology with a compact design, making it ideal for space-constrained environments. The oven's primary function is to ensure uniform heat distribution, which is critical for achieving high-quality results in thermoplastic applications.

The oven's construction includes a base material tray, a heating oven, and an interactive chain mechanism. Its working principle involves two trays for substrate placement, utilizing an interactive access mode. The heating system employs electric heating tubes combined with air mixing technology, ensuring efficient energy use and consistent heating across the entire surface area. This design not only enhances operational efficiency but also reduces the need for extensive labor and floor space.

Key Advantages of the Oven

The Internal Circulating Air Electrically Heating Oven offers several distinct advantages that make it a preferred choice in industrial settings:

- Compact and Space-Efficient Design: With a small footprint, this oven is perfect for installations with limited space, such as small to medium-sized production lines. This design reduces the need for expansive facilities, making it cost-effective for manufacturers.

- Energy-Efficient Heating: The combination of electric heating tubes and air mixing technology ensures that the oven operates with minimal energy consumption while maintaining a uniform temperature distribution. This not only lowers operational costs but also aligns with sustainability goals.

- Easy Operation: The oven is designed for user-friendly operation, requiring minimal training. A single operator can manage the loading and unloading of trays, significantly enhancing labor efficiency and reducing the need for multiple workers.

- Reduced Operational Costs: The simplicity and compactness of the oven contribute to lower maintenance and operational costs. This is particularly beneficial for businesses aiming to optimize their budget while maintaining high production standards.

- Consistent and High-Quality Production: The air mixing heating mode ensures that materials are heated uniformly, resulting in consistent quality. This is crucial for applications where the durability and performance of thermoplastic coatings are paramount.

Applications Across Industries

The versatility of the Internal Circulating Air Electrically Heating Oven extends beyond automotive carpets, making it a valuable asset in various sectors:

Automotive Industry

In the automotive sector, this oven is extensively used for producing automotive carpets, including floor mats, trunk mats, wheel covers, and seat covers. The uniform heat distribution ensures that thermoplastic coatings adhere effectively, enhancing the durability and comfort of the carpets. Additionally, the oven is utilized for other interior components such as door panels, headliners, and soundproofing materials. The consistent heating also plays a role in thermal insulation processes, ensuring that automotive components meet stringent heat resistance standards.

Commercial Textile Production

The oven is ideal for large-scale production of commercial carpets and rugs, which require durable thermoplastic coatings for easy cleaning and resistance to wear. It is also used in the production of wall coverings and upholstery fabrics, where uniform heating ensures effective bonding of coatings to substrates. For protective textiles, the oven's capabilities are crucial in applications requiring water resistance, abrasion resistance, and flame retardancy.

Specialty Flooring and Insulation Products

For temporary event carpets, the oven provides quick and efficient processing, ensuring smooth surfaces and high-quality finishes. It is also used in the creation of soundproofing materials that require thermoplastic coatings to improve acoustic properties. The oven's consistent heating is ideal for producing thermal and acoustic insulation mats used in both construction and automotive industries.

Aerospace and Transportation

In aerospace applications, the oven is used for non-woven carpets and insulation materials, where lightweight and fire-resistant properties are essential. The uniform heat provided by the oven ensures compliance with aerospace standards for flame resistance. Similarly, the oven is applied in the manufacturing of railway and bus flooring, ensuring materials meet safety regulations for public transport vehicles.

Construction and Building Materials

The oven is employed in the production of thermoplastic-coated flooring materials for commercial and industrial spaces. These floors are designed to be durable, slip-resistant, and easy to clean. It also plays a role in producing waterproof membranes and roofing materials, where thermoplastic coatings ensure high water resistance. The oven can be used for applying protective films to building materials, enhancing their durability and UV resistance.

Sports and Recreation Products

The oven is used to produce sports flooring materials, such as gym mats and running tracks, where thermoplastic coatings ensure impact resistance and long-lasting wear. It is also beneficial in manufacturing outdoor gear like tents and protective covers, where the consistent heating ensures durable, weather-resistant coatings.

Packaging Materials

The oven is beneficial in the production of thermoplastic packaging films used in food packaging, medical packaging, and industrial products. These films require consistent, controlled heating to ensure the adhesion of coatings that protect the contents and enhance shelf life.

Technical Specifications

The Internal Circulating Air Electrically Heating Oven is equipped with advanced technology to meet the demands of modern manufacturing. Below is a detailed specification table:

| Parameter | Details |

|---|---|

| Heating Method | Electric heating tubes with air mixing technology |

| Dimensions | Compact design (specific measurements available on product page) |

| Energy Efficiency | High efficiency with minimal energy consumption |

| Operational Capacity | Single operator required for loading/unloading |

| Temperature Range | Customizable to meet specific application needs |

| Material Compatibility | Thermoplastic materials for carpets, textiles, and insulation |

About the Manufacturer: Guangzhou Jingxin Electric Machinery Co., Ltd.

The Internal Circulating Air Electrically Heating Oven is manufactured by Guangzhou Jingxin Electric Machinery Co., Ltd., a company renowned for its innovative solutions in industrial equipment. With a focus on precision engineering and customer-centric design, the company has established itself as a reliable provider of high-quality manufacturing systems. Their expertise in thermoplastic processing and commitment to technological advancement ensure that their products meet the highest industry standards.

For more information about the company and its other products, visit the official website.

Conclusion

The Internal Circulating Air Electrically Heating Oven is a versatile and efficient solution for industries relying on thermoplastic materials. Its compact design, energy efficiency, and ease of operation make it an invaluable asset in various manufacturing processes. Whether in the automotive, construction, or textile industries, this oven delivers consistent quality and performance, ensuring that products meet the highest standards.

For those interested in exploring the Internal Circulating Air Electrically Heating Oven and its applications, the product page provides detailed specifications and additional information. The company's commitment to innovation and quality ensures that their products remain at the forefront of industrial advancements.