Excellence pionnière dans les solutions de fabrication d'intérieurs automobiles

Depuis sa création en 2006, la société Guangjingxin n'a cessé de se développer et d'innover, et elle est désormais devenue une entreprise de référence leader dans le développement de l'industrie des équipements de décoration intérieure automobile.

Nous menons activement des activités de recherche et développement innovantes, avons mis en place une équipe dédiée, obtenu de nombreux brevets technologiques et sommes attentifs aux tendances du secteur et aux besoins de nos clients. Nous lançons en permanence des produits et services innovants pour créer davantage de valeur pour nos clients.

De la conception standardisée au contrôle rigoureux des pièces, en passant par le contrôle précis du processus de production et les tests du produit fini, chaque étape est axée sur l'excellence, le professionnalisme et l'amélioration continue. Nous appliquons rigoureusement les normes ISO 9001, 14001 et 45001 et nous nous efforçons d'atteindre notre objectif à long terme : devenir une référence dans le secteur des équipements de production de pièces intérieures automobiles, grâce à des entreprises de haute technologie, spécialisées et émergentes.

Nous nous engageons à constituer une équipe efficace et dynamique pour répondre aux besoins de nos clients, avec une volonté d'excellence. Elle rassemble des professionnels expérimentés et créatifs. Forts de leurs connaissances professionnelles approfondies et de leur riche expérience pratique, nos collaborateurs collaborent étroitement et communiquent entre eux pour offrir à nos clients une gamme complète de solutions de haute qualité, dépassant ainsi leurs attentes.

En tant que leader du secteur des équipements pour pièces intérieures automobiles, Guang Jingxin se spécialise principalement dans ce domaine. Ses activités comprennent une ligne de production humide et sèche de garnitures de pavillon, une ligne de laminage de tissus, une ligne de production de tapis, une ligne d'assemblage de garnitures de pavillon, ainsi qu'un four pour pièces intérieures, etc.

Contrôler strictement le processus de production, de fabrication et d'assemblage des produits, assurer la qualité des produits et fournir aux clients les meilleurs produits et services de qualité en utilisant des avantages professionnels, une technologie innovante et un système de supervision de qualité strict.

De la pré-communication à la personnalisation du programme, en passant par la mise en œuvre du projet et le service après-vente, nous offrons à nos clients un service client complet et de qualité. Un système de service client performant a été mis en place pour garantir à nos clients une réponse rapide, professionnelle et efficace à tout moment.

Nos produits sont exportés vers le Japon, les États-Unis, le Mexique, la Russie, l'Indonésie, la Thaïlande, le Vietnam et d'autres pays, et ont établi des partenariats stables et à long terme avec de nombreuses sociétés automobiles renommées au pays et à l'étranger.

Tournés vers l'avenir, nous poursuivrons notre quête d'excellence, de professionnalisme et d'innovation technologique. Nous avons déployé des efforts considérables dans le domaine des pièces et équipements intérieurs automobiles. Collaborer avec nos clients et partenaires pour bâtir un avenir meilleur.

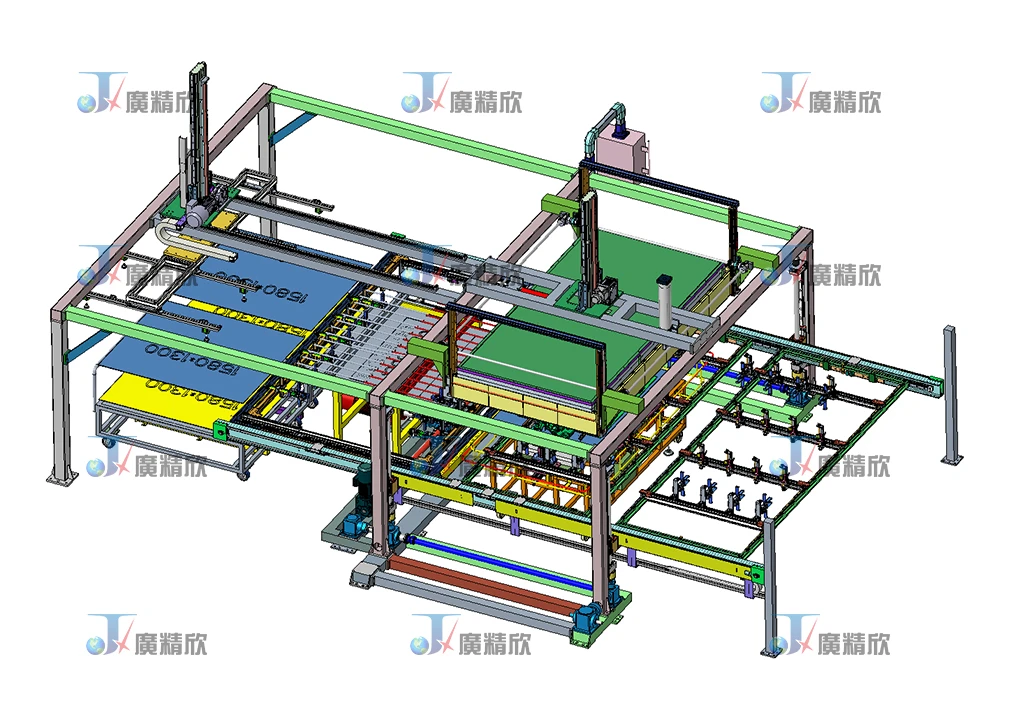

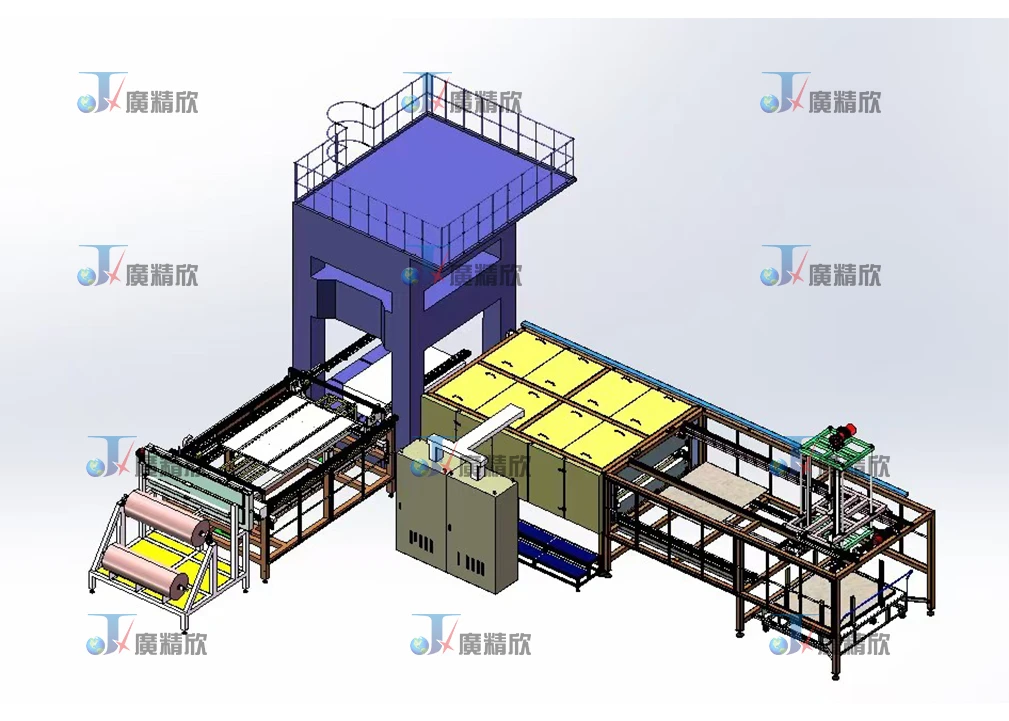

- Ligne de production humide de garnitures de pavillon automobiles

- Ligne de production sèche de garnitures de pavillon automobiles

- Ligne de laminage de tissus automobiles

- Ligne de production de tapis pour automobiles

- Ligne de production de coussinets d'isolation acoustique pour timonerie et intérieur

- Équipement de découpe intérieure

- Ligne d'assemblage de garnitures de pavillon pour automobiles

- Forme intérieure et matrice

- Équipements auxiliaires de production

- Maison

- Produits

- Ligne de production humide de garnitures de pavillon automobiles

- Ligne de production sèche de garnitures de pavillon automobiles

- Ligne de laminage de tissus automobiles

- Ligne de production de tapis pour automobiles

- Ligne de production de coussinets d'isolation acoustique pour timonerie et intérieur

- Équipement de découpe intérieure

- Ligne d'assemblage de garnitures de pavillon pour automobiles

- Forme intérieure et matrice

- Équipements auxiliaires de production

- Application

- À propos de nous

- Ressources

- Nouvelles

- Contact

- produits phares