Introduction

The Internal Circulating Air Electrically Heating Oven represents a cutting-edge solution in the realm of industrial heating systems. Designed specifically for the production of automotive carpets and other thermoplastic materials, this oven combines efficiency, precision, and compact design to meet the demands of modern manufacturing. With its innovative use of electric heating tubes and air mixing technology, the oven ensures uniform heat distribution, enhancing the quality and durability of thermoplastic coatings. This article delves into the product's features, advantages, technical specifications, applications, and the company behind this technology, Chongqing Guang Jingxin Technology Co., Ltd..

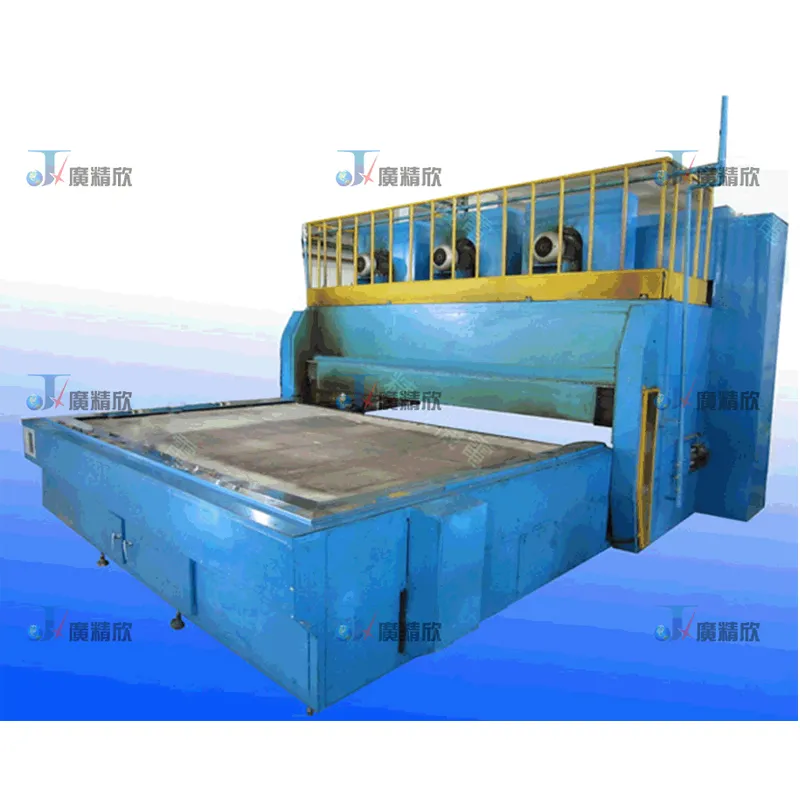

Product Overview

The Internal Circulating Air Electrically Heating Oven is a specialized heating system designed for the production of automotive carpets and other thermoplastic materials. Its compact design and efficient operation make it an ideal choice for manufacturers seeking to optimize space and reduce operational costs. The oven's core components include a base material tray, a heating oven, and an interactive chain mechanism, which work in tandem to streamline the heating process. By utilizing electric heating tubes and an air mixing mode, the oven ensures consistent heat distribution, which is critical for achieving high-quality results in thermoplastic applications.

Key Features and Advantages

1. Compact and Space-Efficient Design

The Internal Circulating Air Electrically Heating Oven is engineered to occupy minimal floor space, making it an excellent fit for small to medium-sized production lines. This design not only conserves valuable manufacturing space but also allows for easy integration into existing workflows. The compact footprint is particularly beneficial for facilities with limited room for expansion, ensuring that manufacturers can maintain high productivity without compromising on space.

2. Energy-Efficient Heating

One of the standout features of this oven is its energy-efficient heating system. The use of electric heating tubes combined with air mixing technology ensures that energy is utilized optimally. This results in reduced power consumption while maintaining consistent and uniform heating across the entire surface area of the substrate. The energy efficiency of the oven not only lowers operational costs but also aligns with modern sustainability goals, making it a responsible choice for eco-conscious manufacturers.

3. Easy Operation

The Internal Circulating Air Electrically Heating Oven is designed with user-friendliness in mind. Its intuitive operation allows for minimal training requirements, enabling a single operator to manage the loading and unloading of trays efficiently. This simplicity in operation enhances labor efficiency, reducing the need for multiple workers and lowering overall labor costs. The oven's side-access design further streamlines the process, ensuring that tasks can be completed swiftly and with ease.

4. Reduced Operational Costs

By combining a compact design with energy-efficient technology, the oven significantly reduces operational costs. The reduction in both energy consumption and labor requirements translates to substantial savings for manufacturers. Additionally, the oven's durability and low maintenance needs contribute to long-term cost-effectiveness, making it a valuable investment for any production facility.

5. Consistent and High-Quality Production

The air mixing heating mode of the Internal Circulating Air Electrically Heating Oven ensures that materials are heated uniformly, which is essential for achieving consistent and high-quality results. This uniformity is particularly critical in the production of automotive carpets, where even heat distribution enhances adhesion and durability. The oven's ability to maintain precise temperature control ensures that thermoplastic coatings meet the highest standards of quality, resulting in products that are heat-resistant, durable, and comfortable under various environmental conditions.

Technical Specifications

| Parameter | Specification |

|---|---|

| Heating Method | Electric heating tubes with air mixing technology |

| Power Supply | 380V, 50Hz |

| Heating Capacity | Up to 1000 kg/h (varies based on material) |

| Operating Temperature Range | 100°C - 250°C |

| Dimensions (L x W x H) | 2000mm x 1200mm x 1500mm |

| Weight | Approx. 800 kg |

| Control System | PLC-based temperature and time control |

| Power Consumption | Approx. 15 kW |

| Material of Construction | Stainless steel and aluminum alloy |

| Number of Trays | 2 (interactive access mode) |

Applications in Various Industries

1. Automotive Industry

The Internal Circulating Air Electrically Heating Oven is extensively used in the automotive industry for the production of automotive carpets, including floor mats, trunk mats, wheel covers, and seat covers. By ensuring uniform heat distribution, the oven enhances the adhesion and durability of thermoplastic coatings, ensuring that carpets remain durable, heat-resistant, and comfortable under a wide range of environmental conditions. Additionally, the oven is utilized in the production of interior components such as door panels, headliners, and soundproofing materials, where consistent heating is crucial for proper molding and adhesion of thermoplastic materials.

2. Commercial Textile Production

In commercial textile production, the oven is ideal for large-scale manufacturing of commercial carpets and rugs, such as those used in hotels, offices, and public spaces. These carpets require a consistent coating of thermoplastic materials for increased durability, heat resistance, and easy cleaning properties. The oven is also used in the production of wall coverings and upholstery fabrics, where uniform heating ensures effective bonding of thermoplastic coatings to the substrate material. Furthermore, it is employed in the creation of protective textiles used in industrial environments or outdoor settings, where coatings are applied for water resistance, abrasion resistance, and flame retardancy.

3. Specialty Flooring and Insulation Products

The oven is used in the production of temporary event carpets, soundproofing materials, and thermal and acoustic insulation mats. For temporary flooring solutions such as event carpets, the oven provides quick and efficient processing, ensuring smooth surfaces and high-quality finishes for high-traffic areas. In the case of soundproofing materials, the oven's consistent heating is essential for creating materials that require thermoplastic coatings to improve their acoustic properties. These materials are commonly used in commercial buildings, conference rooms, theaters, and automotive applications. Additionally, the oven is utilized in the manufacturing of insulation mats for both construction and automotive industries to reduce heat loss and external noise.

4. Aerospace and Transportation

The Internal Circulating Air Electrically Heating Oven is also applied in the aerospace industry for the production of non-woven carpets and insulation materials used in aircraft interiors. The uniform heat provided by the oven ensures that materials meet aerospace standards for flame resistance and structural integrity. Similarly, the oven is used in the manufacturing of railway and bus flooring, ensuring that materials are durable, fire-resistant, and meet safety regulations for public transport vehicles.

5. Construction and Building Materials

In the construction industry, the oven is employed to produce thermoplastic-coated flooring materials for commercial and industrial spaces. These floors are designed to be durable, slip-resistant, and easy to clean, making them ideal for hospitals, schools, and shopping malls. The oven also plays a role in producing waterproof membranes and roofing materials, where the thermoplastic coating applied through the oven ensures high water resistance and long-lasting protection against the elements. Additionally, it is used for applying protective films to building materials such as glass or metal surfaces to enhance scratch resistance, UV protection, and overall durability.

6. Sports and Recreation Products

The oven is used in the production of sports flooring materials, such as gym mats, indoor/outdoor courts, and running tracks, where the thermoplastic coating ensures impact resistance, shock absorption, and long-lasting wear in high-traffic environments. It is also employed in the manufacturing of outdoor gear such as tents, tarps, and protective covers, where the consistent heating ensures durable, weather-resistant coatings for outdoor activities and harsh environments.

7. Packaging Materials

The Internal Circulating Air Electrically Heating Oven is beneficial in the production of thermoplastic packaging films used in food packaging, medical packaging, and industrial products. These films require consistent, controlled heating to ensure the adhesion of coatings that protect the contents and enhance shelf life. The oven's ability to maintain precise temperature control makes it an ideal choice for applications where quality and consistency are paramount.

Company Background: Chongqing Guang Jingxin Technology Co., Ltd.

Chongqing Guang Jingxin Technology Co., Ltd., located in Guangzhou, is a leading manufacturer of industrial equipment, specializing in the production of car mat making machines, non-woven carpet making machines, and machines to make carpet. With years of experience in the industry, the company has established itself as a reliable provider of high-quality, innovative solutions for manufacturing processes. Chongqing Guang Jingxin Technology Co., Ltd. is committed to delivering products that meet the evolving needs of the automotive, textile, and construction industries, ensuring that customers receive equipment that is both efficient and durable.

Industry Standards and NIST Reference

The Internal Circulating Air Electrically Heating Oven is designed to comply with industry standards that prioritize precision, safety, and efficiency. The National Institute of Standards and Technology (NIST), a U.S. government agency, plays a critical role in developing and promoting standards that ensure the accuracy and reliability of measurement technologies. According to NIST, "standards are essential for innovation, economic growth, and the safety of products and services" (NIST, 2025). The principles outlined by NIST align with the design and functionality of the oven, which emphasizes precise temperature control and energy efficiency. By adhering to such standards, Chongqing Guang Jingxin Technology Co., Ltd. ensures that its products meet the highest levels of quality and performance.

Conclusion

The Internal Circulating Air Electrically Heating Oven is a versatile and efficient solution for manufacturers in the automotive, textile, and construction industries. Its compact design, energy efficiency, and ease of operation make it an ideal choice for facilities seeking to optimize space and reduce costs. With its ability to deliver consistent, high-quality results, the oven is a valuable asset for producing thermoplastic materials that meet stringent industry standards. As a leader in industrial equipment, Chongqing Guang Jingxin Technology Co., Ltd. continues to innovate and provide solutions that address the evolving needs of modern manufacturing. By leveraging the principles of precision and efficiency, the company ensures that its products contribute to the advancement of technology and the growth of industries worldwide.