High-Efficiency Carpet Maker Machine for Quality Production

High-Efficiency Carpet Maker Machine for Quality Production

The Evolution of Automotive Carpet Manufacturing: Precision with the Modern carpet maker machine

The automotive industry demands unparalleled quality, durability, and aesthetic appeal from every component, and car carpets are no exception. The modern carpet maker machine, specifically designed for automotive applications, represents the pinnacle of automated manufacturing. These advanced production lines are engineered to meet stringent specifications, ensuring precise fitment, superior acoustics, and enhanced passenger comfort and safety. From raw material input to the final contoured product, the automation capabilities of these machines have revolutionized the sector, enabling high-volume production with consistent quality and reduced operational costs. This article delves into the intricate details of these sophisticated systems, highlighting their technical prowess, operational advantages, and strategic importance in contemporary automotive manufacturing.

Industry Trends in Automotive Carpet Production

The landscape of automotive carpet manufacturing is continually evolving, driven by innovations in material science, automation, and sustainability. Key trends include:

- Advanced Materials: A shift towards more durable, lightweight, acoustic-enhancing, and environmentally friendly materials such as recycled PET fibers, natural fibers, and advanced non-wovens. These materials contribute to vehicle weight reduction, improved fuel efficiency, and enhanced cabin quietness.

- Increased Automation and Robotics: The integration of industrial robots for material handling, precise cutting, and complex assembly tasks, significantly boosting efficiency and consistency. The sophisticated control systems within a modern carpet maker machine enable seamless, lights-out operation.

- Customization and Personalization: Growing demand for bespoke carpet solutions tailored to specific vehicle models and consumer preferences, requiring flexible manufacturing lines capable of rapid changeovers.

- Energy Efficiency and Sustainability: Focus on reducing energy consumption in production processes, optimizing heating systems (like thermal conductive oil), and minimizing waste through precise manufacturing techniques.

- Industry 4.0 Integration: Implementation of IoT sensors, real-time data analytics, and predictive maintenance protocols to optimize uptime, enhance quality control, and streamline production flows.

These trends collectively underscore the need for high-performance, adaptable, and energy-efficient carpet manufacturing machine solutions.

Detailed Process Flow: From Machine Fabrication to Carpet Production

Understanding the capabilities of a modern carpet maker machine involves appreciating both how the machine itself is manufactured and how it subsequently produces high-quality automotive carpets.

1. Manufacturing Process of the Carpet Maker Machine Itself

The creation of a robust and reliable automotive carpet production line involves a sophisticated engineering and manufacturing process for its components:

- Product Materials & Component Fabrication: High-grade structural steel (e.g., Q345B, S355JR) for frames, precision-machined alloys for rollers and guides, and heat-resistant metals for the thermal oil heating system are standard. Fabrication techniques include:

- Casting: Used for complex, high-strength parts that require specific material properties, such as certain gear housings or specialized pump components.

- Forging: Employed for critical components demanding superior strength and fatigue resistance, like heavy-duty shafts and connecting rods within mechanical systems.

- CNC Machining: Essential for achieving the high precision required for rollers, guides, cutting tools, and component interfaces, ensuring smooth operation and tight tolerances.

- Welding: Automated and manual welding processes (MIG, TIG) for structural integrity, conforming to international standards like AWS D1.1.

- Electrical & Control Systems: Integration of advanced PLCs (e.g., Siemens, Allen-Bradley), HMI touchscreens, servo motors, and safety systems (e.g., light curtains, emergency stops).

- Testing Standards & Quality Control: Each machine undergoes rigorous testing:

- Mechanical Performance: Load testing, run-out tests for rollers, alignment checks, and vibration analysis.

- Thermal System Integrity: Pressure testing of thermal oil circuits, temperature uniformity tests, and leakage checks in accordance with standards like ASTM D1310.

- Electrical Safety: Compliance with IEC 60204-1 and CE directives, ensuring operator safety and electromagnetic compatibility.

- Functional Testing: Dry runs and actual material processing tests to validate performance against design specifications.

- Service Life & Maintenance: Designed for an operational service life exceeding 15-20 years with proper maintenance, benefiting from robust component selection and modular design for easy replacement.

2. Operational Process: Automotive Carpet Manufacturing using the Production Line

The "Automotive Carpet Automatic Production Line (Heating By Thermal Conductive Oil)" follows a meticulous multi-stage process:

- Material Feeding: Raw materials, typically non-woven fabric rolls (e.g., polyester, polypropylene, nylon) and backing materials (e.g., heavy layer, EVA, bitumen sheets), are automatically fed into the line. Precision uncoilers ensure smooth, tension-controlled feeding.

- Pre-heating / Lamination: The initial layers are pre-heated to prepare for lamination. The thermal conductive oil heating system provides uniform, indirect heat, crucial for preparing composite materials without degradation. This stage ensures optimal adhesion.

- Forming / Calendering: The heated layers are pressed together under controlled pressure and temperature by calendering rollers. This process fuses the layers, creating a cohesive, multi-layered carpet structure with specified thickness and density. The thermal oil heating ensures precise temperature profiles across the large roller surfaces.

- Molding / Shaping: The composite carpet material is then conveyed to a molding station, often involving a thermoforming press. Here, it is shaped into the complex contours required for specific vehicle floor pans, wheel wells, and other interior areas. The controlled heat from the thermal oil system aids in the material's plasticity and subsequent shape retention.

- Trimming & Edge Finishing: After molding, excess material is precisely trimmed using automated cutting systems (e.g., robotic knife cutting, waterjet, or laser cutting). Edges are then finished (e.g., bound, hemmed) to prevent fraying and ensure a clean, professional appearance.

- Cooling & Inspection: The finished carpet is actively cooled to set its shape and material properties. A final quality inspection station, often incorporating vision systems, checks for defects, dimensional accuracy, and aesthetic consistency before packaging.

Fig 1: Advanced automated material feeding system for a modern carpet manufacturing machine.

Target Industries for this Production Line: Primarily the automotive industry (OEMs and Tier 1 suppliers), but also applicable to specialized transport sectors requiring custom flooring solutions, such as railway coaches or recreational vehicles.

Advantages in Typical Application Scenarios:

- Energy Saving: Thermal conductive oil systems offer superior heat transfer efficiency and more stable temperature control compared to direct heating methods. This reduces energy consumption for consistent heating of large surfaces over extended periods.

- Corrosion Resistance: Components in contact with thermal oil are selected for their high-temperature stability and resistance to oil-related corrosion, ensuring long-term system integrity and minimal maintenance.

- Enhanced Product Quality: Precise temperature control and uniform pressure distribution result in carpets with consistent material properties, excellent dimensional stability, and superior finish.

- High Throughput: Automation at every stage minimizes manual intervention, leading to high production speeds and significantly increased output capacity, crucial for meeting automotive supply chain demands.

Technical Specifications of an Automotive Carpet Automatic Production Line

A detailed look at the core parameters that define the performance and capabilities of a high-end carpet manufacturing machine is essential for B2B decision-makers. The "Automotive Carpet Automatic Production Line (Heating By Thermal Conductive Oil)" offers robust specifications designed for demanding industrial environments.

Product Specification Table: Automotive Carpet Automatic Production Line

| Parameter | Specification |

|---|---|

| Production Capacity | Up to 500-1500 kg/hour (material dependent) |

| Line Speed | 1-10 meters/minute (adjustable) |

| Working Width | Max. 2500 mm (customizable) |

| Heating Method | Thermal Conductive Oil (Closed Loop System) |

| Heating Power | 150 kW - 300 kW (variable, based on configuration) |

| Temperature Control Range | Ambient to 280°C (±1°C accuracy) |

| Roller Diameter (Calendering) | Φ400mm - Φ800mm (hard chrome plated) |

| Pressing Force (Calendering) | Up to 100 kN/meter (pneumatic/hydraulic) |

| Control System | Siemens/Allen-Bradley PLC with HMI Touchscreen |

| Power Supply | 3 Phase, 380V/400V/480V, 50/60Hz (customizable) |

| Overall Dimensions (L x W x H) | Approx. 20-40m x 4m x 3.5m (line configuration dependent) |

| Materials Processed | PP, PET, PA non-wovens, EVA, bitumen, heavy layer composites |

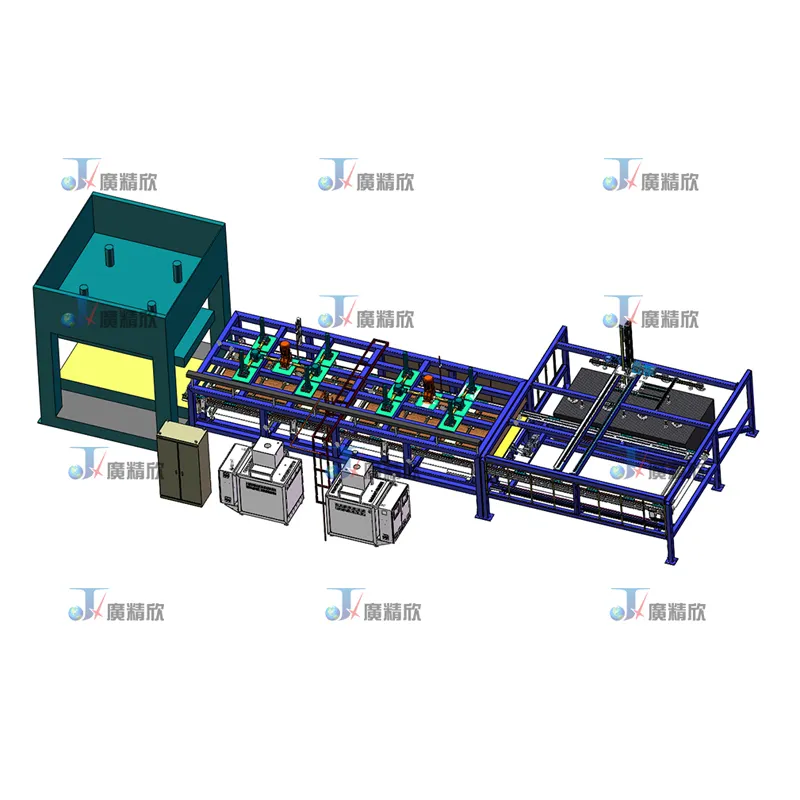

Fig 2: A modular section of the carpet maker machine, showcasing precision engineering.

Application Scenarios and Technical Advantages

Primary Application Scenarios

The "Automotive Carpet Automatic Production Line" is indispensable in several key manufacturing contexts:

- Automotive OEM Production: Directly supplying vehicle assembly lines with precisely molded floor carpets, trunk liners, and wheel arch covers. This requires high throughput, consistent quality, and just-in-time delivery capabilities.

- Automotive Aftermarket & Replacement Parts: Manufacturing replacement carpets for various vehicle models, demanding flexibility for different designs and material specifications.

- Specialty Vehicle Manufacturing: Producing specialized flooring for luxury vehicles, electric vehicles, and custom transport solutions where unique materials and precise geometries are paramount.

- Acoustic and Thermal Insulation Components: Beyond visual carpets, the machine can produce multi-layered composites for under-carpet insulation, critical for NVH (Noise, Vibration, Harshness) reduction and thermal management in vehicles.

Commoda Technica

The advanced design of this carpet maker machine offers significant technical benefits:

- Precise Temperature Control with Thermal Oil: The thermal conductive oil heating system provides extremely stable and uniform heating across large surfaces, critical for consistent lamination and thermoforming of multi-layered materials. This prevents hot spots and material degradation, ensuring superior bond strength and material integrity.

- High Energy Efficiency: Closed-loop thermal oil systems boast high energy transfer efficiency and minimal heat loss. Compared to steam or electrical resistance heating, they can achieve significant energy savings, reducing operational costs for the carpet manufacturing machine.

- Enhanced Durability & Low Maintenance: The use of thermal oil, operating at atmospheric pressure for typical application temperatures, minimizes stress on system components. This leads to extended service life, reduced corrosion, and lower maintenance requirements compared to high-pressure steam systems.

- Automation & Integration: Fully automated material handling, precise digital control via PLC/HMI, and seamless integration of various stages (feeding, heating, pressing, molding, cutting) lead to minimal human intervention, reduced errors, and high throughput.

- Versatilitas Materialis: Capable of processing a wide range of thermoplastic and composite materials, including various non-woven fabrics, EVA, bitumen, and other acoustic/thermal layers, allowing for diverse product offerings.

- Consistent Product Quality: The precision afforded by automated controls and stable heating ensures every carpet produced meets exact dimensional, aesthetic, and functional specifications, crucial for automotive compliance.

Fig 3: Close-up of calendering rollers, heated by thermal conductive oil, for precise material bonding.

Vendor Comparison: Choosing the Right Carpet Manufacturing Machine Partner

Selecting a supplier for a high-value asset like an automotive carpet manufacturing machine requires thorough due diligence. Beyond the initial carpet manufacturing machine price, factors such as technological capability, after-sales support, customization options, and long-term reliability are paramount.

Key Comparison Criteria for Carpet Production Lines

| Criterion | Standard Vendor Offerings | Premium Vendor (e.g., Headlining Line) Advantages |

|---|---|---|

| Heating Technology | Direct electric heating, steam heating (less precise, higher pressure) | Thermal Conductive Oil (highly stable, uniform, energy-efficient, low pressure) |

| Automation & Controls | Basic PLC, manual adjustments, limited data logging | Advanced PLC (Siemens/AB), HMI, SCADA integration, IoT readiness, remote diagnostics |

| Material Handling | Semi-automatic, reliance on manual feeding/take-off | Fully automatic, tension control, robotic integration for cutting/molding |

| Customization | Limited modularity, standard configurations only | Extensive modular design, tailored working width, specialized molding/cutting tools |

| After-Sales Support | Basic warranty, limited on-site support, regional service centers | Comprehensive warranty, global on-site technical assistance, 24/7 remote support, spare parts availability |

| Certifications | CE only, no specific material or process certifications | ISO 9001, CE, specific material/component certifications (e.g., PED for pressure equipment) |

Fig 4: The advanced control panel (HMI) for a modern carpet manufacturing machine, ensuring precise process management.

Customized Solutions and Application Case Studies

Customized Solutions for Unique Requirements

Recognizing that no two manufacturing operations are identical, leading providers of carpet maker machine technology offer extensive customization capabilities. These typically include:

- Line Configuration: Tailoring the length, width, and number of processing stations to fit specific plant layouts and production volumes.

- Material Compatibility: Designing heating and pressing systems optimized for specific material composites (e.g., highly abrasive fibers, sensitive acoustic layers).

- Tooling & Molding: Developing custom molds and cutting tools for intricate automotive carpet shapes and vehicle-specific requirements.

- Integration with Existing Systems: Seamless integration with upstream material preparation (e.g., fiber blending, web forming) and downstream processes (e.g., automated warehousing, robotic kitting).

- Advanced Control Features: Custom software development for specialized process parameters, recipe management, and enhanced data analytics specific to client needs.

Application Case Study: High-Volume OEM Automotive Carpet Production

Client: Global Tier 1 Automotive Interior Supplier, specializing in NVH components.

Challenge: The client needed to upgrade an aging production line to meet increasing demand for complex, multi-layered automotive floor carpets for a new electric vehicle platform. Key requirements included higher throughput, improved material bonding consistency, reduction in energy consumption, and seamless integration with their existing ERP system.

Solution: A custom "Automotive Carpet Automatic Production Line (Heating By Thermal Conductive Oil)" was designed and implemented. This solution featured:

- Enhanced Thermal System: A dual-zone thermal oil heating system for precise temperature profiling, allowing different layers to be conditioned optimally before lamination. This significantly improved bond strength and reduced delamination issues.

- Advanced Robotic Trimming: Integrated robotic six-axis cutting cells with vision systems for precise trimming and edge finishing of complex contours, reducing material waste by 15% and increasing cutting speed by 30%.

- Data Integration & Predictive Maintenance: The PLC control system was integrated with the client's ERP, providing real-time production data and enabling predictive maintenance alerts, which decreased unscheduled downtime by 25%.

- Energy Optimization: The thermal oil system, combined with optimized insulation and heat recovery, resulted in a 20% reduction in heating energy consumption compared to their previous line, directly impacting the overall carpet manufacturing machine price of operation.

Results: The new carpet maker machine enabled the client to increase production capacity by 40% while achieving superior product quality, particularly for critical acoustic properties. Customer feedback highlighted improved dimensional accuracy and consistent material finish. The operational cost savings from reduced energy consumption and waste, coupled with enhanced reliability, provided a rapid return on investment, solidifying the client's position as a preferred supplier for advanced EV platforms.

Fig 5: Example of a finished automotive carpet molded by an automatic production line, ready for installation.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

Frequently Asked Questions (FAQ)

- Q: What types of materials can this carpet maker machine process?

- A: Our Automotive Carpet Automatic Production Line is highly versatile and can process a wide range of materials including PP, PET, PA (nylon) non-woven fabrics, EVA, bitumen, heavy layer composites, and various types of foam or felt for multi-layered automotive carpets and insulation products.

- Q: How does the thermal conductive oil heating system improve efficiency?

- A: Thermal oil heating provides extremely stable and uniform heat distribution, which is crucial for consistent material lamination and molding. Its closed-loop design minimizes energy loss, making it more energy-efficient than direct electric or steam heating, particularly for large-surface, high-temperature applications. It also operates at lower pressures, enhancing safety and reducing maintenance.

- Q: Is the production line customizable for specific vehicle models?

- A: Yes, our systems are designed with modularity and flexibility in mind. We offer extensive customization for working width, line speed, integration of specific tooling (e.g., custom molds for floor pans), and specialized cutting technologies to meet the unique geometric and material requirements of different automotive models.

- Q: What is the typical lead time for a new production line?

- A: Standard configurations typically have a lead time of 6-8 months from order confirmation to factory acceptance testing. Highly customized lines, depending on complexity, may require 9-12 months. Project timelines are always clearly communicated and managed from the outset.

Lead Time and Fulfillment Details

Our commitment is to transparency and efficient project delivery. Following a detailed design and engineering phase, manufacturing and assembly typically span 4-6 months. Factory Acceptance Testing (FAT) is conducted with the client on-site. Shipping, installation, and commissioning at the client's facility usually add another 1-2 months, depending on location and local logistics. Each project is assigned a dedicated project manager to ensure smooth coordination and timely communication.

Warranty Commitments

We stand by the quality and reliability of our equipment. All "Automotive Carpet Automatic Production Lines" come with a comprehensive 12-month warranty on parts and labor from the date of commissioning or 18 months from shipment, whichever comes first. Extended warranty options and service contracts are available to provide long-term peace of mind and minimize operational risks.

Customer Support Information

Our commitment to our clients extends far beyond the sale. We offer multi-faceted support services:

- Technical Support: 24/7 remote technical support via phone and secure online portals, backed by experienced engineers.

- On-site Assistance: Global network of field service engineers available for routine maintenance, troubleshooting, and emergency repairs.

- Spare Parts Management: Comprehensive inventory of critical spare parts with expedited shipping options to minimize downtime.

- Training: Detailed operator and maintenance training programs conducted during commissioning and available as refresher courses.

- Upgrades & Modernization: Services for system upgrades, retrofits, and capacity expansions to ensure the longevity and continued competitiveness of your carpet maker machine.

References

- SAE International. (2022). "Advances in Automotive Interior Materials for NVH Performance." Available at: sae.org

- ISO. (2020). "ISO 9001: Quality management systems – Requirements." Available at: iso.org

- ASTM International. (2021). "Standard Test Methods for Thermal Conductive Materials." Available at: astm.org

- European Commission. (2023). "CE Marking for Machinery Directive 2006/42/EC." Available at: ec.europa.eu

- ScienceDirect. (2021). "Thermal Fluid System Efficiency in Industrial Applications." Available at: sciencedirect.com